Recommended

About us | Advertise with us | Contact us

Quality Assurance / Pharmaceutical Quality Systems in manufacturing medicinal products

Posted: 12 September 2018 | Anastasia Petropoulu | 1 comment

Quality Assurance (QA) covers all aspects that could have an impact on the quality of prescribed pharmaceutical products. This article focuses on some of the Pharmaceutical Quality Systems in relation to QA of manufactured medicines.

Quality Assurance (QA) is a wide concept and covers all aspects that could have an impact on the quality of prescribed pharmaceutical products. The objectives of QA are: to ensure that the prescribed medicine competently provides the desired effect to the person taking it; to protect patients from accidentally being administered an incorrect or contaminated medication; and to ensure medicines comply with the regulation.

Pharmaceutical Quality Systems (PQS) consist of eight pillars, which are designed to provide high quality finished pharmaceutical products, with QA and PQS working together in synergy (Figure 1). Pharmaceutical companies strive to provide high quality products to enable them to enhance their reputation, maximise profit and to provide high quality drugs to humans and animals. To meet these targets, they rely on well-designed PQS, which involve the coordination of quality through processes, with the aim of producing finished products of the highest quality. 1

It is worth noting that the European Medicines Agency (EMA) defines PQS as: “The degree of excellence processed by an item” and “Meeting the requirements of specific customers’ needs”. 6

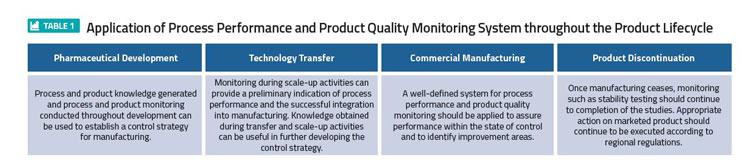

The general model of controlling quality involves standards. Those include: checking the value or degree of the set standards, checking the product for conformity and feeding this back into the initial system and checking stages. 2 The control of quality is an essential process and should be applied at all manufacturing stages; starting with the design, through to assembly of raw materials, in-process, post process and finally the finished products including stability testing. This explains why Quality Control is often described as being the most appropriate Total Quality Control (TQC) concept (Table 1). 4,3

This article will focus on some of the Pharmaceutical Quality Systems in relation to QA of manufactured medicines. As mentioned previously, the eight pillars of PQS constitute a good foundation for discussion (Figure 1). 7

Figure 1: Eight Quality Systems contribute to the high quality of the finished pharmaceutical product

The application of a process performance and product quality monitoring system throughout the product lifecycle is shown in Table 1. This illustrates the most effective monitoring system that provides assurance of the continued capability of processes and controls to produce a product of desired quality and to identify areas for continual improvement, according to PQS Q10. 5

Nevertheless, it is not possible to mention high quality finished pharmaceuticals without mentioning Good Manufacturing Practice (GMP) and Validation. 5 It is well known that all manufacturing stages need quality assurance actions to ensure successful results; but how can they be achieved, and which is the most important action during all the manufacturing stages?

The answers can be found by applying GMP in each step of the manufacturing process. 3 GMP is part of Quality Management that ensures products are consistently produced and controlled to the quality standards appropriate to their intended use and as required by the marketing authorisation or product specification. 3 Furthermore, it ensures the manufactured products meet the end-user’s needs in terms of safety, quality and efficacy. GMP involves monitoring of processes, equipment, personnel and the environment in pharmaceutical companies. 4

GMP is essential in all cases from initial drug trials to commercial launch. To obtain the best product, a manufacturer needs a system in place to ensure regular formulation, processing and composition. 4 Without regulation of a manufacturing process, the consequences cause confusion that might escape notice in the first instance but at some later point will invalidate the safety of the product. This means someone will get harmed or it will cost the manufacturer money. However, the importance of patient safety is what drives companies to improve quality and prevent unnecessary expenditure on manufacturing. 4

GMP applies to all types of pharmaceuticals. For example, a ‘standard product’ is one in which the unit operation and risk assessment of the end product suggests simple equipment ambient conditions; however, this doesn’t mean that the system can be abused. GMP should be applied, and the product manufactured, according to highly-regimented and regulated procedures. 4 On the other hand, sterile medicines require different processes and equipment. 4,2 These types of manufacturing processes often include biotechnology derivatives; where the consistency and potency of bio-preparation, that needs validation and constant monitoring, is often highly variable but may also be associated with issues such as purity. 2 Sterile manufacture tends to be more vigorous in terms of equipment and specialised clean rooms. These specialised conditions and the nature of the drug itself often require additional staff training and a stronger reliance on the Qualified Person (QP) to sign-off. 4

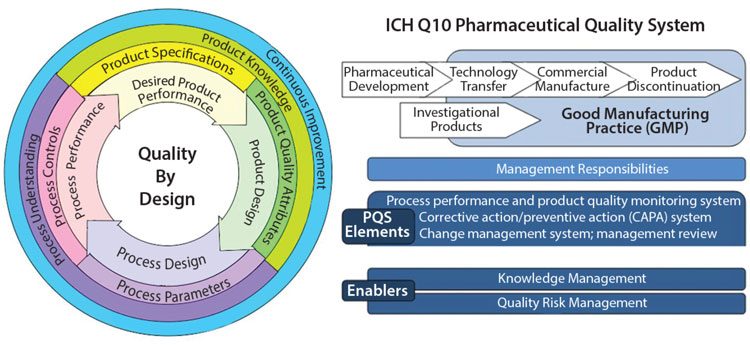

Figure 2 shows how Quality by Design embraces an integrated science and risk-based approach with continuous improvement for the entire product lifecycle. 8 Process validation is needed to underpin confidence in the compatibility and coherence of each individual stage in a process of manufacture of pharmaceuticals. 4

Figure 2: Challenges in Implementing Quality by Design: An Industry Perspective

This represents the biggest part of the validation process in pharmaceutical products. However, cleaning and analytical validation are equally as important in manufacturing validation as in-process, or on-process, control. The aim is to ensure end-product suitability by fragmenting the process into modules with an appropriate consideration of risk and non-compliance to established standards. 4 As such, the essential considerations of any validation of manufacturing should include:

- The importance of following and establishing an environment of GMP

- The site / building / equipment limitations, aspects associated with packaging / storage / handling of the product

- The complexity of routine production, provision of a suitable audit trail in terms of detailed reports and records. 3,4

Additional aspects of higher-end quality in a manufacturing validation include: the probability for consistency of manufacturing and the consequences of inconsistency. Another parameter in the validation process is the use of a pilot trial to identify the point of ‘weakness’ in a particular stage of a manufacturing process where particular attention is required. 4 Pharmaceutical companies should have a system for implementing corrective and preventive actions arising from the investigation of complaints, product rejections, non-conformances, recalls, deviations, audits, regulatory inspections and findings, trends from process performance and product quality monitoring. A structured approach to the investigation process should be used, with the objective of determining the root cause. 3,4

A Quality Risk Management system (Figure 3) involves monitoring and assessing the system’s or procedure’s effectiveness. This mainly involves investigating deviations that have occurred during any step of the manufacturing process, or identifying other factors such as damaged or faulty raw materials, devices or equipment.

Quality risk management

The root cause analysis is identified and documented and finally an evaluation is undertaken to confirm quality objectives were achieved and the quality of the product was not affected. 2 In other words, this system was built to ensure the quality of products by solving various issues or identifying risks and preventing the same happening again.

Risk management principles are used in many areas of business, including pharmaceuticals. The manufacturing and use of medicinal products, including its components, involves some degree of risk, whereas the risk to its quality is just one part of the overall risk. 4 A robust quality risk management programme can ensure the high quality of pharmaceuticals by providing a proactive means of identifying and controlling potential quality issues during development and manufacturing. Effective quality risk management can provide regulators with greater assurance of a company’s ability to deal with possible risks and can positively affect the level of direct regulatory oversight. 4,6

Efficient quality management results from the correct interfacing of quality control, quality assurance and quality improvement initiatives. It is achieved through acting on feedback from the people involved in the product supply chain. A quality cycle is a group of experts who meet with the aim of improving the quality of manufacturing processes, the environment, health and safety etc. Effective communication between the investors in the group can result in an improvement over and above those routine improvements. 4,6

In pharmaceutical manufacturing, QA is the parameter used to ensure prescribed medicine effectively produces the desired effect on the person taking it. The PQS, part of QA system, was designed to help manufacturers achieve the target for high quality finished pharmaceutical products; leading to the required level of drug regulations and providing efficacy and safety for patients. 4 The parameters for approaching these targets include:

- The pharmaceutical product is designed to meet the need and performance requirements

- The process is designed to consistently meet product critical quality attributes 8

- Processes, equipment, personnel and deviations are identified and controlled in an appropriate manner

- The whole manufacturing process is constantly monitored and updated to enable consistency in quality over time.

The application of Pharmaceutical Quality Systems in pharmaceutical products can extend to pharmaceutical development, which should facilitate innovation and continual improvement of prescribed medication. 2,6 It is the tool with which to achieve product realisation by designing, planning, implementing, maintaining and continuously improving a system, to allow the consistent delivery of pharmaceuticals with appropriate quality attributes. 4,6

- Article: Viper. 2015. Quality In Pharmaceutical Industry Management, UK essays

- Book: Beaney AM. 2006. Quality Assurance of Aseptic Preparation Services, fourth edition, published by pharmaceutical press

- Book: MHRA. 2017. Rules and Guidance for Pharmaceutical Manufacturers and Distributors, London Pharmaceutical Press, Chapter 2 EU Guidance on Good Manufacturing Practice

- Book: Sarker DK. 2008. Quality Systems and Control for Pharmaceuticals, School of Pharmacy and Biomedical Sciences University of Brighton, UK

- Article: ICH Harmonised Tripartite Guideline. 2008. Pharmaceutical Quality Systems, Q10, step 4 version

- Article: EUROPEAN MEDICINES AGENCY, science medicines health. 2015. EMA/CHMP/ICH/24235/2006, ICH guideline Q9 on Quality risk management, step 5

- Image: Morley L, CEO, EUSA, Pharma. 2016. Total Quality Service Management, Regulis, UK

- Image: Torres L. 2015. Challenges in Implementing Quality By Design: An Industry Perspective, BioProcess International

- Image: Quality Risk Manager for Manufacturing Systems; a Contamination Control Perspective, T. PDA Technical Report No 54-5 (TR 54-5)

Anastasia Petropoulu is a Radiopharmacy Technician / Clinical Scientist in the Radiopharmacy Department of University Hospital Bristol NHS Foundation Trust, Anastasia obtained a certificate in Health and Science followed by a BSc Hons degree in Pharmaceutical Science at the University of the West of England. She has gained experience in Quality Assurance / Quality Systems (QA / QS) by completing work in both pharmacy and the food industry. Anastasia has worked in Greece in the food industry as a Quality Assurance technician and in the UK pharmaceutical industry at Norbrook Laboratories Ltd in Northern Ireland and gained experience in testing raw materials as a Quality Control Analyst. She has also worked at NHSBT Bristol and the University Hospital Bristol NHS Foundation Trust, where she assisted in the production of parenteral nutrition and cytotoxic medicines. She currently works in Radiopharmacy as a Radiopharmacy Technician / Clinical Scientist where she applies PQS in the manufacturing process of radiopharmaceuticals.

The rest of this content is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here

Issue 4 2018

Related topics

Aseptic Processing , Industry Insight , Manufacturing , QA/QC

Related organisations

European Medicines Agency.

Next-Generation Rapid mRNA Vaccine CQA Analytics

Novel medicine could address short stature in children

By Catherine Eckford (European Pharmaceutical Review)

CRISPR technologies fuelling haematological innovations

EFPIA reaction to European Parliament plenary vote

New partnership to advance European oligonucleotide manufacturing

One response to “quality assurance / pharmaceutical quality systems in manufacturing medicinal products”.

Very well defined about the role of quality and most of the companies should remember that quality should be built inside the system.

Thanks for such a great post Anastasia Petropoulu.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

© Russell Publishing Limited , 2010-2024. All rights reserved.

Website development by e-Motive Media Limited .

Cookie Settings

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorised as ”Necessary” are stored on your browser as they are as essential for the working of basic functionalities of the website. For our other types of cookies “Advertising & Targeting”, “Analytics” and “Performance”, these help us analyse and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these different types of cookies. But opting out of some of these cookies may have an effect on your browsing experience. You can adjust the available sliders to ‘Enabled’ or ‘Disabled’, then click ‘Save and Accept’. View our Cookie Policy page.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Modern Aspects of Pharmaceutical Quality Assurance pp 1–7 Cite as

Introduction: Quality Assurance from Perspective of Pharmaceutical Industry

- Minal Ghante 4 ,

- Shrikant Dargude 4 ,

- Arpana Patil 5 &

- Vidhya Bhusari 4

- First Online: 12 March 2024

36 Accesses

Pharmaceutical development requires product quality, design, and operational efficiency. Pharmaceutical development is a multifarious process that encompasses various facets, including product quality, design, and operational efficiency. Operational excellence helps improve pharmaceutical product quality by optimizing manufacturing processes, reducing waste, and enhancing productivity augmenting operational efficiency and effectiveness. Quality assurance is essential to ensure that pharmaceutical products are safe, effective, and meet quality standards. The integration of operational excellence and quality management systems can help achieve pharmaceutical product quality and operational excellence goals. This chapter elaborates upon the intricate concept of quality assurance in the pharmaceutical industry, with a meticulous focus on the manifold perspectives that undergird its implementation. It underscores the paramount importance of quality assurance in ensuring the safety and efficacy of pharmaceutical products and expounds upon the regulatory frameworks that have been instituted to ensure compliance. This chapter also scrutinizes the multifarious challenges that the pharmaceutical industry faces in implementing quality assurance, including the exigency of a robust quality management system, the salience of risk management, and the pivotal role of technology in ensuring quality. In sum, this chapter provides a comprehensive, all-encompassing overview of quality assurance in the pharmaceutical industry and its indispensability in guaranteeing the safety and efficacy of pharmaceutical products.

This is a preview of subscription content, log in via an institution .

Buying options

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Durable hardcover edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout

Purchases are for personal use only

Levi L, Walker GC, Pugsley LI. Quality control of pharmaceuticals. Can Med Assoc J. 1964;91(15):781–5.

CAS PubMed PubMed Central Google Scholar

Fellows M, Friedli T, Li Y, et al. Benchmarking the quality practices of global pharmaceutical manufacturing to advance supply chain resilience. AAPS J. 2022;24 https://doi.org/10.1208/s12248-022-00761-7 .

International conference on harmonisation of technical requirements for registration of pharmaceuticals for human use pharmaceutical quality system Q10

Google Scholar

Kieffer RG. The changing role of quality assurance in the pharmaceutical industry. PDA J Pharm Sci Technol. 2014;68:313–9.

Article PubMed Google Scholar

VanDuyse SA, Fulford MJ, Bartlett MG. ICH Q10 pharmaceutical quality system guidance: understanding its impact on pharmaceutical quality. AAPS J. 2021;23 https://doi.org/10.1208/s12248-021-00657-y .

Haleem RM, Salem MY, Fatahallah FA, Abdelfattah LE. Quality in the pharmaceutical industry – a literature review. Saudi Pharm J. 2015;23:463–9.

Lebrun P, Giacoletti K, Scherder T, et al. A quality by design approach for longitudinal quality attributes. J Biopharm Stat. 2015;25(2):247–59.

Suleman S, Belew S, Kebebe D, et al. Quality-by-design principles applied to the establishment of a pharmaceutical quality control laboratory in a resource-limited setting: the lab water. Int J Anal Chem. 2022;2022 https://doi.org/10.1155/2022/2062406 .

Korakianiti E, Rekkas D. Statistical thinking and knowledge management for quality-driven design and manufacturing in pharmaceuticals. Pharm Res. 2011;28:1465–79.

Article CAS PubMed Google Scholar

Friedli T, Basu P, Bellm D, Werani J. Leading pharmaceutical operational excellence outstanding practices and cases. Berlin/Heidelberg: Springer; 2013.

Book Google Scholar

Download references

Author information

Authors and affiliations.

Department of Pharmaceutical Quality Assurance, Sinhgad Technical Education Society’s, Smt. Kashibai Navale College of Pharmacy (Kondhwa), Savitribai Phule Pune University, Pune, India

Minal Ghante, Shrikant Dargude & Vidhya Bhusari

Department of Pharmaceutics, Sinhgad Technical Education Society’s Smt. Kashibai Navale College of Pharmacy (Kondhwa), Pune, India

Arpana Patil

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Minal Ghante .

Editor information

Editors and affiliations.

Department of Pharmaceutical Quality Assurance, Smt. Kashibai Navale College of Pharmacy, Pune, Maharashtra, India

Minal Ghante

Manohar Potdar

Vidhya Bhusari

Rights and permissions

Reprints and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter.

Ghante, M., Dargude, S., Patil, A., Bhusari, V. (2024). Introduction: Quality Assurance from Perspective of Pharmaceutical Industry. In: Ghante, M., Potdar, M., Bhusari, V. (eds) Modern Aspects of Pharmaceutical Quality Assurance. Springer, Singapore. https://doi.org/10.1007/978-981-99-9271-3_1

Download citation

DOI : https://doi.org/10.1007/978-981-99-9271-3_1

Published : 12 March 2024

Publisher Name : Springer, Singapore

Print ISBN : 978-981-99-9270-6

Online ISBN : 978-981-99-9271-3

eBook Packages : Chemistry and Materials Science Chemistry and Material Science (R0)

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

- July 25, 2022

The importance of quality in the pharmaceutical industry

A viewpoint by June Sum , Consultant.

Quality is one of the most important management principles for any organization regardless of industry. This is particularly true for the pharmaceutical sector: maintaining quality product standards is essential for the prevention and treatment of numerous medical disorders.

Although the pharmaceutical industry has been around for centuries, in recent years we have experienced an increase in the number of drugs being launched in the market. As a result of this increase, the need for quality assurance and quality control measures has risen. For instance, drug manufacturers must follow strict guidelines to get their drugs approved by the FDA (Food and Drug Administration) in the United States. Such guidelines include requirements for testing, manufacturing, labelling, packaging, storing and distributing pharmaceuticals.

Quality Management

Quality management is a crucial component of any successful organization as it ensures that products and services are produced and distributed consistently and effectively.

Good Manufacturing Practice (GMP) is the element of quality management that ensures goods are produced and controlled according to the quality standards of their intended use and that they meet the requirements specified by the marketing authorization or product specification. Additionally, it ensures that manufactured goods are safe, of high quality, and effective. For pharmaceutical companies, GMP entails the monitoring of procedures, apparatuses, employees, and environments.

Quality planning, quality control, and quality assurance are all important aspects of quality management too. We’ll look at what quality management is, why it’s important, and the main components and principles of quality management in this article.

Quality planning

Quality planning refers to the process of defining the quality requirements and standards of a product or service and identifying the resources needed to meet such requirements and standards. The planning phase is the first stage in establishing a good quality management system. It is in this phase that companies define their baseline quality objectives. Once goals have been set, organizations must determine what is required to achieve these objectives and what procedures should be implemented to ensure their success. During this stage of the quality management process, it is important to keep in mind the following considerations:

- The organization’s definition of success

- How often procedures and processes will be evaluated for improvement

- If the stakeholders have any quality-related priorities, goals, or ambitions

- If there are any legal procedures or standards that must be followed in order to achieve the desired quality level

Quality Control

Quality control is the next step in the quality management process. At this stage, companies assess through physical inspection and testing whether their plan is achievable. They must verify that all requirements are being met and identify any issues that may need to be corrected. It is therefore important to pay close attention to all product elements, that is, every component of the product and all manufacturing procedures.

The data collected should be presented in a way that makes it simple to examine. Document management software enables teams to create and easily share histograms, run charts and cause-and-effect diagrams.

Quality control involves ensuring standards and procedures are being met. This may include conformance testing as well as feeding information back into the initial system and examination phases. It is important to apply quality management throughout the entire manufacturing process.

Quality Assurance

Quality Assurance (QA) is a broad concept that encompasses all factors that could potentially affect the quality of prescribed pharmaceutical products. The goal of quality assurance is to verify that prescribed medications provide the desired effect to its consumers; safeguarding patients from receiving defective or contaminated prescriptions by accident; and ensuring that medications comply with regulations.

Pharmaceutical Quality Systems (PQS) consist of eight pillars that help companies oversee quality management methods with ease: allowing the consistent delivery of pharmaceutical products of the highest quality.

The eight pillars of PQS:

- Quality risk management

- Quality management system consultancy & design

- Good distribution practice & good manufacturing practice compliance

- Standard operating procedures development

- Qualified person & responsible person provision

- Inspection preparation & support

Quality Improvement

Once the quality management process is complete, reviewing the results and developing an action plan for improvement is key. Continuously performing the quality control management process, re-evaluating both the procedure and the product while keeping compliance in mind, will result in a better final product, happier customers and more profit.

At Amaris Consulting, we offer a wide spectrum of services to pharmaceutical, medical device, and biotechnology companies. Our quality experts assist businesses in meeting and exceeding customer expectations while supporting you throughout the entire drug development life cycle.

Share Post:

Amaris Consulting is your stepping stone to cross rivers of change, meet challenges, and achieve all your projects with success.

- Life Sciences

- IS & Digital

- Engineering

©2024 Amaris Consulting

Get in touch

Practices in the Pharmaceutical Industry Essay

Several controversies have been hitting the pharmaceutical industry in the last few years. The larger percentage of the controversies ranges from Medicare fraud to high-priced medications that are marketed by these firms. From the researcher’s point of view, big pharmaceutical corporations are putting huge profits on top of patients, spiraling shammed public relations campaigns and more. Before the recent changes, Medicare CEOs and these companies had been reported to have involved in frauds worth billions of shillings.

The indications are that the costs of the drugs are rising more rapidly than any other thing a patient can pay for. It has been found that medications are the most rapidly increasing part of the patient health care bill. It is argued that most of the patient’s expenditure on drugs has also risen.

The reason is that the quantities of drugs that are being prescribed have increased. Moreover, the practitioners are prescribing new ineffective drugs that are more expensive than the old effective less costly drugs.

More appalling is the fact that the prices of these consistently prescribed drugs are in a great deal jacked up, in most cases a number of times a year. The discounts as well as other incentives the medical practitioners such as the oncologists are receiving are used as a reason for hiking the prices. The government as well as other researchers has found that these benefits are unwarranted.

The most shocking thing about these drug price controversies is that the trusted health care providers have an ulterior motive behind these prescriptions. Researchers found out that there is a correlation between the methods through which cancer doctors are being paid to the choice of drugs they use in a particular treatment of cancer such as chemotherapy (Abelson par.9).

Once the oncologists have decided on the type of treatment, the mode of payment influences the type of drug prescription. As opposed to the expectations those who are fairly paid are likely to prescribe more expensive drugs.

Reports indicate that most of the pharmaceutical firms’ representatives provide hand-outs to influence medical practitioners to recommend the drugs they represent. Going by analytic reviews of the articles on the diabetes drugs Avandia, it is true that drug manufacturers are paying medical experts to make positive conclusions about their drugs safety and effectiveness. In fact, Avandia case is one out of many (Bakalar par.1).

There are several cases where the medical expert opinions are influenced by the financial handouts. It is agreed among the medical professionals that the interaction between the pharmaceutical companies and the health providers are not in the best interest of the patient. Moreover, most of the doctors agree that solicitation of drugs directly from these companies compromises the ethical standards and impractical, most can be influenced by free gifts and hand outs from these companies.

Some sections of the medical profession argue that their treatment decisions are for the best interest of the patients (Abelson par.7). The argument is that doctors only prescribe drugs that are clinically recommended. Moreover, quality health care must be more costly. However, in the case of cancer therapy, there is no any evidence that one type of chemotherapy drugs are working better than the others.

In this case, the medical practitioners have the wide array of manufacturers or the pharmaceutical agents to choose from. Therefore, regardless of their persistence that their therapy decisions are based on what they feel is best for the patient; medical practitioners are influenced by other factors such as payment policies as well as other financial influences coming from the drug manufacturers.

Works Cited

Abelson, Reed. Pay Method Said to Sway Drug Choices of Oncologists . 2006. Web.

Bakalar, Nicholas. Study Sees a Slant in Articles on Drug . 2010. Web.

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2024, January 6). Practices in the Pharmaceutical Industry. https://ivypanda.com/essays/practices-in-the-pharmaceutical-industry-essay/

"Practices in the Pharmaceutical Industry." IvyPanda , 6 Jan. 2024, ivypanda.com/essays/practices-in-the-pharmaceutical-industry-essay/.

IvyPanda . (2024) 'Practices in the Pharmaceutical Industry'. 6 January.

IvyPanda . 2024. "Practices in the Pharmaceutical Industry." January 6, 2024. https://ivypanda.com/essays/practices-in-the-pharmaceutical-industry-essay/.

1. IvyPanda . "Practices in the Pharmaceutical Industry." January 6, 2024. https://ivypanda.com/essays/practices-in-the-pharmaceutical-industry-essay/.

Bibliography

IvyPanda . "Practices in the Pharmaceutical Industry." January 6, 2024. https://ivypanda.com/essays/practices-in-the-pharmaceutical-industry-essay/.

- The Plight of the Community Oncology Medicare Patient

- Ethical Issues in GlaxoSmithKline

- Practice of Qualitative Research Report

- Breaking Bad News by Medical Practitioners

- Medical Marijuana Legalization by National Football League

- Ambulance Service with Inappropriate Call Outs Burden

- A De-Emphasis Technique for Delivering Bad News

- Stock-Outs and Their Impact on the Company’s Progress

- Thyroid Cancer Chemotherapy

- The Presentation Delivery: Training Package

- Baseline Pharmaceutical Engineering Guides

- Use of Psychotropic Medications in the Treatment of Drug Abuse

- Problem of Hydrocodone Addiction in US

- Action of Nandrolone on the Cardiovascular, Renal, Blood and Respiratory Systems

- Use of Methadone, Methadone clinics, and Needle Exchange Programs

- RECRUITMENT

Technical Writing Tips for Pharmaceutical Quality Assurance Students

October 8, 2019

One aspect of pharmaceutical quality assurance that is very important, and that anyone working in the industry should be aware of, is technical writing. Technical writing is different from other kinds of writing, because it is focused first and foremost on clarity. Long sentences and descriptions might work well in an article or book, but not for a piece of technical writing.

Whether you find yourself working with Standard Operation Procedures (SOPs), Master Batch Records (MBRs), or other pieces of writing, clarity and accuracy will be essential. With a few helpful hints, you’ll be on track to writing these documents in a manner that everyone can understand and easily follow.

Working in quality assurance means working on different documents

Continue reading to learn more about technical writing and find out how you can build your own skills!

What to Think About Before Getting Started

Strong technical writing skill is essential for quality assurance in pharmaceutical operations that require different documents.

Before you get started with a piece of technical writing, you should be sure to make a plan.

- Before you even commit to writing your first sentence, think about what your objective is.

- Consider who you are writing for and what information you must communicate.

- In some cases, it is a good idea to make a preliminary writing document such as an outline or a graphic organizer before you start writing.

When planning your document, consider ways that you can enhance brevity. In fact, you should never use two words when one will do. Your writing should get to the point. In technical writing, there is no room for descriptive language. Write what needs to be said in a way that it can be well understood, and keep sentences short and easy to follow so that no misunderstandings occur.

Writing should be clear and easy to understand

Word Choice for Clarity in Pharmaceutical Quality Assurance Writing

Regardless of whether you’re writing SOPs, MBRs, or another document during your career in pharmaceutical quality assurance , there are a few guidelines or rules of technical writing that can be applied across all situations. Word choice and clarity are a couple of things you’ll want to keep in mind, to be sure your point gets across.

- Word Choice – This is a matter of making your writing easy to understand. When you are deciding which words to use to say something, choose the word that will cause the least amount of confusion, and which can be processed with the most ease.

- Clarity – Make sure that what is clear to you is also clear for the person that might read your work. Your choice of words will help you to do this, as well as clarification when necessary. For example, if you use an acronym, make sure that the reader knows what that acronym means in order to ensure that your writing is as clear as possible.

If you can, have someone re-read your work to make sure it’s clear

Are you interested in earning a Pharmaceutical Quality Assurance diploma ?

Contact AAPS today to learn more about our programs!

Categories: Pharmaceutical Quality Control & Assurance

Tags: pharmaceutical quality assurance , pharmaceutical quality assurance diploma , Quality assurance in pharmaceutical

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

Interested in AAPS? Contact us directly or provide your information for a call back.

Toronto campus, hours of operation.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Int J Health Sci (Qassim)

- v.7(3); 2013 Nov

Pharmaceuticals Safety Practices-A Comparative Pilot Study

Introduction.

The safety of medicine is essential for the safety of patients. Inappropriate drug storage, expiration dates, sharing prescription drugs, self medication habits and misuse of some drugs are contributing factors affecting medication safety. One or more of these factors may lead to serious health complications and even death.

The purpose of this study was to highlight the common errors and pharmaceutical malpractices that people usually engage in on a daily basis and to correlate these to culture, gender and educational levels. This may spread awareness in an easy and understandable manner and provide certain guidelines to drug consumers ensuring that pharmaceutical preparations are used correctly and safely.

Two hundred questionnaires were randomly distributed in two countries; Saudi Arabia and India. The collected data were statistically analyzed.

Outcomes and conclusion

Results showed that alarming percentages of various participants were using pharmaceuticals inappropriately due to carelessness, unawareness or intentional mistakes. Therefore, active participation by health care professionals is essential for the prevention of drug misuse. Increasing population awareness about self medication, products expiration, pharmaceuticals labels and optimum storage conditions would minimize the adverse effects and may even be life saving.

Medication and patient safety measures are indispensable in any health care system. Medication safety is the design of medication administration strategy to ensure the five rights; right patient, right medication, right dose, right route and right time. ( 1 ) While patient safety refers to the sustained, proactive process of identifying, avoiding and rapidly resolving errors, omissions, mishaps and miscommunications that could affect a patient’s healing, health or well-being at any point, at any time, in any care setting. ( 1 )

Adverse drug events are common, costly and serious problems. These include adverse drug reactions and medication errors. ( 2 ) The latter means any preventable actions that may lead to patient harm. These errors may include sharing prescription drugs, self medication habits, medication misuse, administration of drugs after expiration date, carelessness of reading the labels and misplacement of the products.

Whether it is prescription or Over-the-Counter (OTC), no medicine is without risk. ( 3 ) Up to half of people who use medicines, do not use them as prescribed. ( 4 ) Home medicine chests, which are often kept in inappropriate locations and containers, promote opportunities for irrational consumption, exchanging of medicines, irresponsible self-medication, unintentional toxic exposure and intentional intoxication (drug misuse among the adolescents). ( 5 ) Proper methods of storage and preservation of drugs are of great importance for maintenance of their potency. ( 6 ) Depending on the product’s composition, it may expire long before its expiration date if it has not been stored and handled properly. ( 7 ) Some of the environmental factors such as air, chemicals, insects and bacterial and fungal growth increase the risk of contamination. ( 8 , 9 ) Others like moisture, light and temperature variations may adversely affect the different dosage forms of drugs and may lower their original potency. ( 8 , 9 ) Summer heat can potentially degrade the drug which is often unnoticed especially in hot countries. ( 4 ) Reading the label before purchasing any sort of cosmetic product or medicine is less practiced by the consumers. ( 6 ) Most people find it difficult to understand the terminology and instructions given in the leaflet due to lack of its simple explanation especially for those with low literacy level. ( 10 ) A high incidence of inappropriate medication use has been documented in the older non-institutionalized population ( 11 – 13 ) and in long-term care. ( 14 ) Therefore, the risk of medication errors may be high in older home healthcare patients. Such patients are frequent medication users, and advanced age and frailty may increase their susceptibility to adverse medication effects. ( 15 )

This goes not only for medicines but also for cosmetics as well. Many people use makeup on a daily basis which is a major factor of concern since a considerable amount of cosmetics can actually be absorbed into the skin or breathed into the lungs. ( 16 )

Global drug safety depends on strong national systems that monitor the development and quality of medicines, report their harmful effects, and provide accurate information for their safe use. ( 3 , 7 ) Saudi Food and Drug Authority (SFDA) and Central Drugs Standard Control Organization (CDSCO) are the two regional regulatory authorities that assure the safety, quality and efficacy of medications in Saudi Arabia (SA) and India (IN), respectively. ( 17 , 18 ) Research has shown that medical errors and the associated injuries are a significant problem as these errors occur frequently and have significant clinical and financial consequences. ( 19 , 20 ) Hence, preventing medication errors is a blueprint for change in medication safety. ( 21 ) Recent research reports have raised concern about the protocols of administration of various pharmaceuticals that are used in health care systems and their effects on medication and patient safety in order to minimize the index of errors to the lowest. ( 22 – 26 )

Literature data from survey studies on the prevalence of common medication errors at home is lacking. Medication-related safety incidents are a source of concern not only to patients but also to policy makers and clinicians. ( 22 ) To promote adherence to medication and patient safety measures there is an urgent need to highlight the common errors that individuals make during their daily life when using pharmaceutical preparations either due to unawareness or carelessness. Comparing such practices between people of different genders, education levels or from different communities would help in determining their predisposing factors. Therefore, this snapshot study was carried out to determine how individuals use pharmaceuticals and highlight their daily home malpractices in order to focus on ways to minimize the index of errors and improve the patients’ health, recovery and well-being.

Materials and Methods

- Individuals from Saudi Arabia and India.

- Questionnaire made of 23 questions.

Inclusion Criteria

- Individuals of both genders

- Individuals aged above 18 years

Exclusion Criteria

- Uneducated people who could not read or write

- Individuals aged less than 18 years

This research design was cross sectional and used a questionnaire survey distributed randomly among selected populations in Saudi Arabia and India. The questionnaire had multiple questions pertaining to pharmaceutical preparations used and kept at home and self medication habits. Some of these questions were about the placement of drugs stored at home whether they are prescription or OTC, keeping the leftover drugs for future use (standby drugs), checking the labels and expiration dates of pharmaceuticals, understanding instructions given, sharing medications and completion of the recommended dose.

A questionnaire comprising of 38 questions was designed after referring to previous studies and interviews with five senior pharmacists who had over ten years of experience in the academic field. ( 27 ) Pretesting was done by distributing the questionnaire to a sample of 10 participants selected randomly from both countries. The responses from those individuals were subjected to a factor analysis. As a result, a minor change to certain terminology was made to some questions and the total number of questions was reduced to 23 questions. The content validity was finally assessed by discussion and rating by academics and students.

A pilot questionnaire was given to 10 participants and then re-given to them after 45 days to test reliability and reproducibility. The Cronbach’s alpha was used to test the reliability, the values for the questions ranged from 0.82 to 0.95 with an overall Cronbach’s alpha of 0.92 showing excellent reliability.

Two hundred hard copies (paper forms) were randomly distributed among populations. In addition, soft copies of the questionnaire using my easy survey website ( www.myeasysurvey.com ) were available. A systematic random sampling technique was used when questionnaires were distributed. The participants were selected from Riyadh Colleges of Dentistry and Pharmacy directory list that included all students’ names and every fourth name (aged 18 years and above) was chosen. Every third customer entering some pharmacy stores in both countries was selected to fill in a questionnaire. A total of 200 questionnaires were distributed, participants were requested to fill in the questionnaires after reading and signing an informed consent statement. After three months, 166 filled questionnaires were returned. In Saudi Arabia; all hundred distributed questionnaires were filled and returned while only 61 were returned in India. Five additional questionnaires (late reporting) from Saudi Arabia were also included in the study. Collected data was analyzed using Statistical Product and Service Solutions (SPSS) software analysis tool (version 18). Chi square test with p < 0.05 was used to check for significance of differences in responses.

Total of 166 questionnaires from paper and online versions were filled and returned with a response rate of 83%. From those, 105 came from Saudi populations and 61 from Indian populations. There were 48 females and 117 males with an indeterminate case. Of these, 84 were students, 62 had bachelor degrees, 11 had postgraduate degrees, and 9 were indeterminate ( Figure 1 ).

Study populations divided into different categories

Significant variations between participants of different cultures, genders and educational levels have been found upon comparison of their daily practices when using pharmaceutical preparations ( Tables 1 – 3 ). Pharmaceutical malpractices have been noticed from populations in both countries with significant differences in certain responses from each one ( Table 1 ). On gender basis; females were found to be notably more curious than males when dealing with pharmaceuticals ( Table 2 ). Remarkable variations between participants of different educational levels were found when using pharmaceutical products ( Table 3 ).

Saudi and Indian populations’ safety measures when using pharmaceuticals

Differences in responses about pharmaceuticals safety practices based on gender basis

Level of education in relation to participants’ responses of pharmaceuticals safety

Comparison of the safety measures practiced by the study participants when using pharmaceuticals has been done on the basis of culture, gender and education. The study asked about all pharmaceutical preparations that people were using on their daily life including prescription and OTC medications, cosmetic and various health care products. Selecting people from different communities would significantly help in understanding some of the leading factors to pharmaceuticals safety practices. Especially within Saudi and Indian communities where there are many challenges to health care services although their governments have given high priority to the development of health care systems ( 28 – 30 ). On the other hand, comparing participants of both genders and different educational levels for their attitudes when using pharmaceuticals had determined how those factors would affect their safety measures when using pharmaceuticals and hence their health and well being.

Analysis of the data revealed that most of the involved populations did not usually obtain full information from pharmacists about the pharmaceutical product they purchase in pharmacy stores ( Tables 1 – 3 ). This could be due to self dependence on reading the products’ labels. However, the results showed that more than 60% of the respondents did not try to read the leaflets of their medications. Females and postgraduates were more curious to read such leaflets. This could be explained as the majority (> 70%) of the males and graduates could not understand the terminology found in the leaflets ( Tables 2 and and3 3 ).

A few (17%) of the participants were careful enough to ask the pharmacist what to do with their medications leftover. This explains why more than half of them (> 50%) stored the leftover until further needed. Females and postgraduates were significantly the best in dealing with their medications leftover ( Tables 2 and and3). 3 ). More than half of the total participants shared their prescribed medications with others while about three quarters of them use some medications for purposes other than those labeled on the package without consultation. With respect to educational levels, it was found that, the higher the educational degree, the lesser the percentage of such malpractices ( Table 3 ). Sharing and repeating prescription medications is a common habit in developing countries where the strict laws for dispensing prescription drugs are lacking. Although 40% of the study participants repeated their prescribed medications whenever they felt sick, Saudi and postgraduate populations significantly avoided such habit when compared to Indian and graduate ones, respectively ( Tables 1 and and3 3 ).

Saudi, female and postgraduate participants were found to be remarkably more aware about the suitable instructions to be followed to ensure the safe storage of pharmaceutical preparations at home ( Tables 1 – 3 ). About two third of the total population thought that humid places (kitchens and bathrooms) or dining tables were the best places to keep pharmaceuticals. There were no significant differences between either genders or people with different education levels or from different cultures regarding this matter. This might be due to ease of accessibility and/or avoidance of forgetting taking the medicaments on their respective timing. Participants were used to practice such despite the damage occurred to certain products if kept in those places. More than three quarters of participants stored their medications in the presence of adolescents noting that Indian-, female- and student- participants were found to engage more in such behavioral mistakes ( Tables 1 – 3 ). The latter might lead to some intentional drug intoxications by those teenagers and increased rates of suicides.

Although all of the populations involved in the study were educated, most of them did not care to keep a list of emergency numbers or contacts of the closest drug poison centers in case of accidents or drug poisoning. About three quarters of the participants did not keep standard measurement tool for accurate drug dosage or check the approval of regulation authorities for food and drug safety (RAFDS) of the pharmaceuticals upon purchasing from pharmacies or retail markets. Some participants stated that if the product was available in the market, they thought no need to check this as it should have been approved already while others believed that it was hard to go through the product’s label and understand it. More than three quarters of the participants were found not to bother to update themselves about medications. Saudi-and female- participants were particularly more interested for being updated to be the first to know about harmful and useless products so they could avoid any complications before they occur ( Tables 1 and and2 2 ).

Indicating all precautions about pharmaceuticals would be extremely difficult. The prudent alternative is to make reasonable judgments based on the best available evidences combined with successful experiences in health care. ( 31 ) One of the limitations of the study is the difficulty to access different families in order to ask them about their attitudes when using pharmaceutical products. From each house, only one questionnaire is to be filled and represents what they usually do. The responses from Saudi Arabia were higher than that from India as the study was mainly done in Saudi Arabia and the distance played a factor on that. Accordingly, this is considered a snapshot study in order to achieve its main goal to capture an insight into the different individuals practice towards pharmaceuticals that they are using and keeping at home in two developing countries.

Increased vulnerabilities of drug consumers might be due to increased errors, most of which might be unintentional or due to the consumer’s carelessness. Although the limited number of samples, this pilot study focused on the common mistakes that the consumers of pharmaceuticals usually make and highlighted their increased percentages between those consumers. In addition, the study discussed the predisposing factors and reasons of such practices. A detailed study with a greater sample size is still necessary to elaborate on the factors unreached by this study.

Neglecting such malpractices can have a serious negative impact not only on individuals and community but also on the national economy. Hence, increasing population awareness about self medication, drug expiration, medications labels and optimum storage conditions would minimize the drug adverse events and even be life saving. The former would be achieved by the participation of health care professionals and researchers that should underline those mistakes and the reasons for their occurrence. People work in pharmaceutical industry also have a great responsibility to improve medication safety by supplying the market with products that are stable in most conditions, easily identified from each others with labels which are easy to be read and understood. The role of policy makers comes afterwards to set the rules which aim to minimize the index of errors to minimum, hence, improving the medication and patient safety practices.

Acknowledgment

The authors would like to thank Dr Sharat Pani for his help and support during the work of the study.

- Sign In / Manage Profile

- Learn About Membership

- Join AMWA Now

- Access Member Benefits

- Member Directory

- Recognition & Awards

- AMWA Code of Ethics

- AMWA Education

- Online Learning

- Live Webinars

- Essential Skills

- ES Certificate

- Onsite Training

- Events Calendar

- AMWA Career

- Search the Directory

- Create a Listing

- Compensation and Salary Information

- Advance Your Professional Career

- Expert Tips for Freelance Medical Writing

- Guide to Becoming a Medical Writer

- Guide to Regulatory Writing

- Medical Editing Guide

- Value of Medical Writing

- Employer Resources

- About Medical Communication

- View the Current MWCs

- About the MWC Commission

- AMWA Resources

- Current Issue

- Read Recent Issues

- Past Issue Archive

- Instructions for Contributors

- Index (1985-2023)

- Medical Communication News

- Member Resource Library

- Mini Tutorials

- Position Statements and Guidelines

- Regulatory Writer Training eBook

- Online Store

- AMWA Event Calendar

- Registration

- Onsite Experience

- Sponsors and Exhibitors

- AMWA Online Learning

Expand Your Skills to Write for the Pharmaceutical Industry

Let’s explore the distinct types of writing in this niche, then identify the challenges you must overcome to succeed as a writer in this rapidly expanding industry.

Types of Writing for the Pharmaceutical Industry

If you’re a veteran medical writer, you already have a solid understanding of these broad types of medical writing :

- Regulatory writing

- Scientific publications

- Health communications

- Education for professionals

- Promotional writing

- Grantsmanship

Whether you write for a pharmaceutical company, medical device company, or some other type of organization, pharmaceutical content can fall into several of the above categories.

Writers for the pharmaceutical industry are likely to do one (or more) of the following types of writing, which are further described in The Writing Cooperative ’s “ Writing for the Pharmaceutical Industry ”:

- Pharmaceutical marketing communications. Medical drugs and devices are marketed to consumers and health care professionals. As a medical marketing communicator, you’ll need to write plain language summaries of critical information—from drug contraindications to clear indications for use. You will also craft content such as slide decks and brochures to educate physicians about these products. If you work for a health care organization rather than a drug or medical device company, you might create content for the hospital’s website, newsletter, or other marketing materials.

- Regulatory writing . Writers in this niche focus on documents required by regulatory agencies such as the FDA’s Center for Drug Evaluation and Research (CDER). You could write manuals for conducting clinical trials (known as investigator brochures), clinical study reports, or submissions such as Investigational New Drug Applications (INDs), Marketing Authorization Applications (MAAs), or New Drug Applications (NDAs).

- Continuing medical education (CME) course writing . Like professionals in other industries, doctors, nurses, and other medical professionals must earn continuing education credits to maintain their licenses. Writing content for these courses is a lucrative, rewarding option for medical communicators with a love for learning.

- Technical writing. Pharmaceutical technical writers create technical documentation such as medical device user manuals or reference guides. This type of writing requires incredible attention to detail. The writing can seem dry—especially for those shifting from health communication or medical marketing—but a great technical writer can also enjoy the satisfaction of translating dense information into helpful material for a variety of readers.

Challenges of Writing for the Pharmaceutical Industry

The pharmaceutical field is increasingly fast‑paced. From novel drugs to the development of generic specialty medications, the rapid changes can feel overwhelming for medical writers who must keep up with changing trends and regulations.

Here are some of the greatest challenges of crafting documents for this industry:

Lack of standardized training

The baseline experience of regulatory writers is uneven or absent due to the lack of formal, standardized training in many organizations. Regulatory writer training is necessary, but it’s difficult to create because it consists of so many components, including hands‑on education. Extensive training also takes place over multiple years.

Writers for the pharmaceutical industry—especially those involved in regulatory document creation—should have the following:

- High‑level knowledge of the drug development process

- Strong medical writing skills

- Technical aptitude with a variety of resources, from Adobe Acrobat to Clinical Data Interchange Standards Consortium (CDISC) Glossary

AMWA’s training roadmap for regulatory writers offers a helpful outline of the regulatory topics that are most important and demonstrates how certain topics and skills build on the preceding ones.

Rapidly evolving therapies and standards

Addressing this challenge requires a deep commitment to continued learning. In Managed Care Executive ’s January article “Top Issues Facing Pharma in 2020,” author Frieda Wiley, PharmD, reviewed several hot-button topics in the pharmaceutical industry’s “era of exponential change.”

In this industry, you might write about a variety of therapeutic categories with new products every year. You could find yourself creating documents covering everything from gene therapy to specialty drugs for rare diseases and disorders. You should also be prepared for last‑minute document revisions due to late‑breaking study results or urgent regulatory changes.

Attention to detail

Writing for the pharmaceutical industry is not for everyone. Writers must be fastidious and undistracted—even when the topics are highly technical or dry.

The pharmaceutical industry can be challenging even for experienced medical writers . The key is to commit to learning, maintain unwavering attention to detail, and determine a niche that maximizes your background and skills.

November 16, 2020 at 8:00 AM

American Medical Writers Association

AMWA is the leading resource for medical communicators. The AMWA Blog is developed in partnership with community members who work every day to create clear communications that lead to better health and well-being.

View all posts >

Blog subscribe.

- Career development (43)

- Core knowledge and skills (37)

- Freelancing (28)

- Health communication (17)

- Writing and editing mechanics (17)

- Soft Skills (15)

- Getting Started (11)

- Regulatory writing (11)

- Scientific publications (11)

- Management & Leadership (8)

- Education for professionals (6)

- Grantsmanship (3)

- Promotional writing (1)

- Sales Training (1)

American Medical Writers Association 9841 Washingtonian Blvd, Suite 500-26 Gaithersburg, MD 20878

phone: 240. 238. 0940 fax: 301. 294. 9006 [email protected]

About Us Contact AMWA Staff © 2023 AMWA / Policies

QUICK LINKS

- AMWA Journal

- Certification

- Engage Online Community

- Medical Writing & Communication Conference

CONNECT WITH US

- Support AMWA

- Advertise with AMWA

Membership Management Software Powered by YourMembership :: Legal

Synthetic Chemistry

In-vitro biology services, in-vitro adme services, route scouting, non-gmp kilo lab, analytical support services.

A sneak peek into our facility

Piramal has been offering from mg to gm scale discovery chemistries to its customers from North America, Europe and Asia

Piramal’s in vitro Biology is designed to provide best in class support to our clients to enable their preclinical drug discovery.

Piramal's in-vitro labs provide ADME services for faster and improved decision making for our Chemistry clients

Assisting our partners in discovering and developing efficient and cost effective routes

Piramal’s fully-equipped kilo-lab allows for rapid development of scalable and robust chemical processes using advanced process methodologies

The chemists at Piramal are supported by a specialist & fully dedicated analytical team which operates 24/7 with suites containing advanced analytical equipment

Piramal Discovery Solutions offers a comprehensive range of Contract Research Services from our state-of-the-art research centre in India to support drug discovery activities.

Development, process r&d services, pre-formulation studies, pharmaceutical drug development services, regulatory services, clinical trial services.

Process development for small molecule intermediates, APIs and HPAPIs

Expert approach ensures quality of drugs from discovery to commercial supply

Pharmaceutical Development of oral solids, liquids, creams, ointments, and sterile injectable.

Range of services, including method development, stability studies, validation and transfer

Expert clinical & regulatory support across all phases of drug development programs

Clinical Trial Manufacturing, Packaging and Supply Services using our global network

Piramal offers a comprehensive range of development services to help the customer address complex drug development challenges and bring more products to the market faster.

Manufacturing, api manufacturing, finished dosage manufacturing.

- Oral Solids

- Sterile Injectables

- Liquids, Creams and Ointments

- Cytotoxic and Potent Compounds

Lifecycle Management

We provide the manufacture and supply of Active Pharmaceutical Ingredients (APIs) on an integrated manufacturing model across North America, Europe and Asia

Piramal Pharma Solutions offers the development and manufacturing of High Potency API services from its Riverview facility

With very small quantities of active pharmaceutical ingredients (API) or drug-able candidate molecules

Piramal offers contract manufacturing services for a wide variety of solid dose forms. Our global manufacturing sites located across North America, Europe and India offer the highest standards of quality and service to the customers.

Antibody drug conjugation, proof-of-concept studies, process development and scale up, adc manufacturing, adc fill/finish, analytical development services.

Piramal offers a fast-track early stage development service for your ADC programmes. Whether you are selecting your candidate mAb, linker or toxin

Piramal offers ADC process development and scale-up through Tox manufacture and into GMP manufacture

World-leading multi-product facility for clinical and commercial manufacturing of antibody drug conjugates (ADCs)

Piramal offers aseptic filling of ADC drug product through our FDA-inspected state-of- the-art manufacturing facility in Lexington, KY

Analytical development team covers a wide range of analytical methods from small molecule analysis through to cell killing assays and ELISA development

Piramal is the world leader in delivering customer-centric solutions in the field of Antibody Drug Conjugates (ADCs) to global pharmaceutical companies.

Generic apis, mumbai, india, generic api products.

- API Product List

- APIs (Under Development)

- Peptide API Product List

- Peptide APIs (Under Development)

We have an experienced team of over 28 scientists including 8 Ph.D.’s dedicated to innovation in new product development, cost optimization, and novel route scouting projects

Piramal’s Generic API division offers an indigenous basket of off-patent APIs for global markets. With the declining pipeline of new drugs in the pharmaceutical industry, our customers are looking for off-patent APIs with competitive cost and quality.

Nutrition solutions.

- Foods & Beverages

- Staple Foods

- Infant Nutrition

- Bakery Foods

- Pharma & Nutraceuticals

- Dry-Encapsulated

- Dry-Cold Water Soluble

- Oily-Liquid

- Animal Nutrition

- Customized Vitamin Mineral Premix-Powder Form

- Customized Oily & Water Miscible Vitamin Products

- Retinol & Diluted Forms

- Other Oily Forms For Cosmetic Industry

- Institutional

- Micro Nutrient Powder(MNP)

- Vitamin A Solution

- Premixes For Ready to Eat Therapeutic & Supplementary

- MOH Mandated Fortification Programs

Product List

With key focus on research and strong manufacturing capabilities, we deliver a portfolio of premium solutions to customers in more than 80 countries

Piramal Nutrition Solutions (PNS), division of Piramal Enterprises Limited (PEL) is one of the leading manufacturers of Straight Vitamins and Mineral premixes.

Dear Partners,

Necessitated by the unprecedented situation created by Covid-19, several industry events and tradeshows across the world have been postponed or stand cancelled. While we were looking forward to meet you, we at Piramal Pharma Solutions have had to take several precautionary measures to protect both our employees and customers, worldwide.

As we move forward in these extraordinary times, we want to assure you that that we are operational by taking the right safety measures and abundant precautions to ensure that we continue to support you and your patients.

While all of us are working remotely for now, you can schedule a discussion with us and we would be glad to help ensure you meet your pharmaceutical development and supply needs and thereby, your clinical and commercial timelines.

Please feel free to reach out to us at: [email protected]

Our best wishes to colleagues, friends and family.

Best Regards, Piramal Pharma Solutions

Thank You For Your Interest. Please Enter Your Details

Technical writing is not a new idea. Any type of communication written for and about industry and business with a focus on products and/or services is technical writing. Almost everyone within a company has written a form of technical document – from the résumé that was submitted to gain employment to the email sent to a co-worker to writing an investigative report. According to a survey of business leaders, as many as two-thirds of salaried employees have some writing responsibility, and all employees must have writing ability, especially with the increase in company email communication.

Technical writing skills are extremely important for any industry, but even more so when manufacturing pharmaceutical drugs. In this industry, if a batch record step is unclear or contains a mistake, it could have several types of negative consequences. Product could be unusable and clients could be lost if the mistake is caught. Employees could be hurt and lawsuits filed. Or, worse, the mistake could escape attention and end up impacting a patient, causing harm or death. The importance of good technical writing cannot be ignored as the science of pharmaceutical drug manufacturing depends on clear and accurate reporting. An otherwise meticulous document can appear flawed if it is poorly written wasting company time and resources.

It is difficult, however, to find employees who have content knowledge of their profession and also the skills needed to write a technical document. It is even rarer to find an employee who has taken a course in technical writing, and, as many colleges do not offer technical writing as a concentration in the English department, it is even harder to find an employee who has a degree in technical writing. With this information, it is not hard to believe the statistic that one-fourth of college graduates are not only poor writers, but lack proper communication skills altogether.

The Journal for Quality and Participation reports on several companies that lost big when it came to poor writing. Computer company Coleco eventually went out of business when customers who purchased its new line of computers found the instruction manual unreadable and returned the items. An oil company spent thousands of dollars to develop a new pesticide that had been written five years earlier by a technician in the same company but was so poorly written no one finished the report. A nuclear plant sent in a sales order for “ten foot long lengths” and instead of getting the ten-foot lengths they wanted, they instead received ten one-foot lengths. And, the list goes on.

According to the previously mentioned survey of business leaders, a little more than forty percent of companies offered or required additional training for employees with writing deficiencies. This training came with an annual cost of as much as three billion dollars. Add in the cost of poor writing resulting in liability to a company and that number grows substantially. Having just one staff technical writer could bring down this cost tremendously. Technical writers are diverse enough to fit into the pharmaceutical industry. Well-educated writers are able to explore a product and communicate its usefulness, process, what it means, and how it should be used clearly to the reader using as few words as possible.

In the pharmaceutical industry, Good Manufacturing Practices (GMPs) require instruction documents like Standard Operating Procedures (SOPs) to be error free and written in an orderly fashion. It is as important for manufacturing documentation, reporting on problems, laboratory test methods, batch production records, etc. to all be crystal clear in its instructions. If employees are lacking in the skills to create crystal-clear, error-free instructions, then how are companies compensating for the deficit?

By having the necessary skills to research, understand complicated information, and tailor writing to many different readers, a technical writer within the pharmaceutical company is essential. By having a staff technical writer, companies can also save on training others within the company on the traits of technical writing. Any good technical writer can put together a session for others in the company detailing the traits common to technical writing and strategies for using them. Everyone within the company producing documents must be able to communicate detailed manufacturing procedures with simplification and directness reaching the end goal quickly and effectively. The steps must be written with extreme accuracy as lives depend on it.

A technical writing session for employees should include an introduction to technical writing. A brief description of clarity, conciseness, document design, audience, and accuracy are helpful. Then, the session should focus on strategies for using these traits in company documents like SOPs and batch production records. See Figure 1.

Figure 1: Technical Writing Strategies for SOPs

By creating good quality content and having the necessary skill to tailor a document to achieve maximum clarity, technical writers can help achieve positive results for any business. More importantly, they can train others within the company to produce a more sound technical document. Customers and clients will value the consistent professional look in company documents and communications and will feel informed and trusting of the information provided to them. This, in turn, can bring in more customers and clients, increase value for stakeholders, and improve employee relations throughout the company. By hiring a technical writer, not only is your business going to increase but you save on the three billion dollars’ worth of training writing-deficient employees each year and decrease the problems resulting from unclear writing plaguing businesses.

Be sure to evaluate the technical writing capabilities of Contract Development and Manufacuring Organizations (CDMOs) before starting your next project. Piramal Pharma Solutions knows the importance of producing sound, technical documents in the pharmaceutical industry. We employ technical writing to ensure more understandable SOPs and facilitate more executable batch records. Clients appreciate the consistency among the documentation and our employees appreciate the clarity of instructions and guidelines. Overall, we are more efficient as our documents become more efficient.

References: “Writing: A Ticket to Work…Or a Ticket out: A Survey of Business Leaders.” The National Commission on Writing. 2004. “Total Quality Business Writing.” The Journal for Quality and Participation . 1995.

Posted in Blogs on Oct 31, 2016

- Environment

- Information Science

- Social Issues

- Argumentative

- Cause and Effect

- Classification

- Compare and Contrast

- Descriptive

- Exemplification

- Informative

- Controversial

- Exploratory

- What Is an Essay

- Length of an Essay

- Generate Ideas

- Types of Essays

- Structuring an Essay

- Outline For Essay

- Essay Introduction

- Thesis Statement

- Body of an Essay

- Writing a Conclusion

- Essay Writing Tips

- Drafting an Essay

- Revision Process

- Fix a Broken Essay

- Format of an Essay

- Essay Examples

- Essay Checklist

- Essay Writing Service

- Pay for Research Paper

- Write My Research Paper

- Write My Essay

- Custom Essay Writing Service