Recycling System ’Looop’ Helps H&M Transform Unwanted Garments into New Fashion Favourites

We are thrilled to soon offer customers in Sweden the possibility to transform unwanted garments into new fashion favourites with the help from our new garment-to-garment recycling system ‘Looop’. We are committed to closing the loop on fashion and this machine visualizes to customers that old textiles hold a value and should never go to waste.

Looop opens to the public in one of our Drottninggatan stores in Stockholm on October 12. This is the first time this garment-to-garment recycling system is shown in store by a fashion retailer and H&M is proud to soon offer customers the opportunity to watch this container-sized machine recycle their old textiles into something new. This is part of a bigger plan - our ambition is to become fully circular and climate positive and we are working with many exciting projects to reach this goal. We must innovate materials and processes while inspiring customers to keep their garments in use for as long as possible.

“We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources. Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire,”

says Pascal Brun, Head of Sustainability at H&M.

Looop uses a technique that dissembles and assembles old garments into new ones. The garments are cleaned, shredded into fibres and spun into new yarn which is then knitted into new fashion finds. Some sustainably sourced virgin materials need to be added during the process, and we of course work to make this share as small as possible. The system uses no water and no chemicals, thus having a significantly lower environmental impact than when producing garments from scratch.

H&M wants to lead the change towards a sustainable fashion industry. In 2013 we became the first fashion retailer with a global garment collecting program. Now, we are taking the next step with our garment-to-garment recycling system Looop. For 100 Swedish kronor, members of our loyalty club can use Looop to transform their old garment into a new favourite. For non-members the fee is 150 Swedish kronor. All proceeds go to projects related to research on materials. By 2030 we aim for all our materials to be either recycled or sourced in a more sustainable way, a figure that for 2019 was at 57%.

Looop is created by the non-profit H&M Foundation, together with research partner HKRITA (The Hong Kong Research Institute of Textiles and Apparel) and Hong Kong-based yarn spinner Novetex Textiles. For more information on how Looop works check out: https://www2.hm.com/en_gb/life/culture/inside-h-m/meet-the-machine-turning-old-into-new.html

H&M's 'looop' recycling system transforms unwanted garments into new fashion favorites

what if an unwanted pair of socks could change the fashion system? H&M has developed a machine that dissembles and assembles old clothes into new ones with ‘looop’ — the world’s first in-store recycling system. ‘looop’ opened to the public in an H&M store in stockholm on october 12, 2020, with customers able to watch the container-sized machine recycle their old textiles into something new. here’s how it works — an unwanted garment is fed into the machine to get cleaned, shredded and spun into yarn. after about five hours, a new knitted garment is made from the piece put into the machine. the system uses no water and no chemicals, thus having a significantly lower environmental impact than producing garments from scratch.

in eight steps, ‘looop’ turns old garments into new ones: 1. the old garment is sprayed with ozone to remove any microorganisms; 2. the garment is shredded down into small chunks of fabric fibres; 3. shredded chunks are then filtered to remove dirt, and extra virgin material is added for strength; 4. the clean fibre mix is straightened into a fibre web and then pulled into slivers; 5. multiple fibre slivers are combined to create even stronger, thicker slivers; 6. the thick fibre slivers are spun to create a single yarn thread; 7. single yarn threads are doubled and twisted together to increase their strength; 8. finally, the yarn is then knitted into a new, ready-to-wear design.

the innovative technology behind H&M’s ‘looop’ has been developed by the hong kong research institute of textiles and apparel (HKRITA) in collaboration with the non-profit H&M foundation . as of now, ‘looop’ is the only in-store recycling machine, but HKRITA will license the technology widely to help the entire industry become more circular.

the garment-to-garment recycling system is part of a bigger plan for the company, which strives to become fully circular and climate positive. ‘we must innovate materials and processes while inspiring customers to keep their garments in use for as long as possible. by 2030 we aim for all our materials to be either recycled or sourced in a more sustainable way, a figure that for 2019 was at 57%.’

‘we are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources,’ says pascal brun, head of sustainability at H&M. ‘getting customers on board is key to achieve real change and we are so excited to see what looop will inspire.’

take a look at the designs ‘looop’ can remake your pre-loved clothing into, here .

happening now! croatian furniture company prostoria stands as an example of a different and more traditional approach based on the evolution from the local factuality of all actors involved in the production process. explore prostoria on designboom!

H&M (3)

- recycling (337)

PRODUCT LIBRARY

a diverse digital database that acts as a valuable guide in gaining insight and information about a product directly from the manufacturer, and serves as a rich reference point in developing a project or scheme.

- love hultén (12)

- sound art (65)

- car design (807)

- electric automobiles (647)

- materials (76)

- car concept (362)

- space travel design (98)

designboom will always be there for you

H&M - "Looop" Initiative

Fashion, clothing and textiles

What is it? “Looop” is a new in-store recycling initiative being piloted by H&M. It is a garment-to-garment recycling system, designed to incentivize customers to recycle their old clothes (H&M 2020b, c). Although some sustainably sourced virgin materials must be added to strengthen the yarn, the system transforms old clothing into new ones, while not using any water or chemicals (H&M, 2020a).

Why is this important ? Recycling rates in the fashion industry are low. Higher recycling rates can – theoretically – decouple fashion from virgin material inputs. This is important, because the clothing industry is one of the most polluting industries. It is responsible for around 10% of total global greenhouse gas emissions (more than the shipping and international aviation industries combined) (Niinimäki et al, 2020). Conventional (non-organic) cotton production is a vast consumer of water and pesticides. 20,000 liters of water are required to produce 1 kg of cotton (WWF, 2020). Polyester and nylon are made of manmade materials consuming energy and resources. Further, when these fossil-fuel based fibres break down, they can release large amounts of micro-plastics into the environment (De Falco et al., 2019). Clothing is a massive source of obsolescence and waste. The Ellen MacArthur Foundation (2017) estimates that “ USD 500 billion value is lost every year due to clothing being barely worn and rarely recycled ”.

Main resource strategy : Closing the loop by recycling fibres from old clothing and textiles to make new garments.

Business model aspects :

- Value Proposition: New value for old clothes.

- Value Creation & Delivery: Customers can bring in their old garments to the store and have them made into new ones. The Looop recycling system, first cleans and disassembles old garments, then spins new yarn and knits it into new items. The entire process takes 5 hours and is visible to customers. Currently, customers can choose between a sweater, scarf or a baby blanket as the final products (H&M, 2020d).

- Value Capture: For a fee of €10 – €15, customers can have their clothes transformed into a new item (H&M, 2020d).

Business model experimentation practices : Initial pilot in Stockholm store.

Sustainability outcomes : No reported data available yet. The initiative is currently in its pilot stage and was launched on 12 th October 2020, at the Drottninggatan store in Stockholm, Sweden (Parija, 2020).

De Falco, F., Di Pace, E., Cocca, M., & Avella, M. (2019). The contribution of washing processes of synthetic clothes to microplastic pollution. Scientific Reports, 9(1). https://doi.org/10.1038/s41598-019-43023-x

Ellen MacArthur Foundation. (2017). A new textiles economy: Redesigning fashion’s future. Accessed 7 December 2020 at: https://www.ellenmacarthurfoundation.org/our-work/activities/make-fashion-circular/report

H&M. (2020a). H&M Group Sustainability Performance Report 2019. URL: https://hmgroup.com/content/dam/hmgroup/groupsite/documents/masterlanguage/CSR/reports/2019_Sustainability_report/H%26M%20Group%20Sustainability%20Performance%20Report%202019.pdf

H&M. (2020b). Let’s close the loop. Accessed 18 November 2020 at: https://www2.hm.com/en_gb/hm-sustainability/lets-change.html/close-the-loop

H&M. (2020c). Magazine: From old to new with Looop. Accessed 18 November 2020 at: https://www2.hm.com/sv_se/life/culture/inside-h-m/meet-the-machine-turning-old-into-new.html

H&M. (2020d). News Article: Recycling system ’Looop’ helps H&M transform unwanted garments into new fashion favourites. Accessed 18 November 2020 at: https://about.hm.com/news/general-news-2020/recycling-system--looop--helps-h-m-transform-unwanted-garments-i.html

Kavilanz, Parija. (2020). H&M will let people convert old clothing items into new ones at Stockholm store. CNN Business. URL: https://edition.cnn.com/2020/10/08/business/hm-clothing-recycling/index.html

Niinimäki, Kirsi; Peters, Greg; Dahlbo, Helena; Perry, Patsy; Rissanen, Timo; and Gwilt, Alison. (2020). The environmental price of fast fashion. Nature Reviews Earth & Environment. 1. 189-200. DOI: 10.1038/s43017-020-0039-9

WWF. (2020). Cotton | Industries | WWF. World Wildlife Fund. Accessed 1 December 2020 at: https://www.worldwildlife.org/industries/cotton

About project Circular X

Project Circular X is about ‘Experimentation with Circular Service Business Models’. It is an ambitious research project funded by the European Research Council (ERC) which supports top researchers from anywhere in the world. Project CIRCULAR X runs from 2020-2025. The project is led by Principal Investigator (PI) Prof Dr Nancy Bocken, who is joined by a multidisciplinary team of researchers at Maastricht Sustainability Institute (MSI), Maastricht School of Business and Economics, Maastricht University. The project cooperates with businesses who want to innovate towards the circular economy.

Project Circular X addresses a new and urgent issue: experimentation with circular service business models (CSBMs). Examples of such new business models include companies shifting from selling products to selling services and introducing lifelong warrantees to extend product lifetimes. However, CSBMs are far from mainstream and research focused on experimentation is little understood. The research aims to conduct interdisciplinary research with 4 objectives:

- Advancing understanding of CSBMs; their emergence and impacts

- Advancing knowledge on CSBM experimentation

- Developing CSBM experimentation tools

- Designing and deploying CSBM experimentation labs

Funding source

This project has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme, grant agreement No. 850159.

Using this information

When you cite this publication, please use the following source:

Circular X. (2021) Case study: H&M “Looop” Initiative. Accessed from www.circularx.eu

Beni - Secondhand shopping browser extension

Arveco - 'Outic' workwear as a service

Our website uses cookies to improve your browsing experience on our website. Please read our Cookie Policy for more information.

To revisit this article, visit My Profile, then View saved stories .

H&M Takes a Step Toward Circularity With a Collection of Garments Made From Waste

By Emily Farra

According to the New Standard Institute, fashion is responsible for between 4 and 10% of global carbon emissions, with 150 billion new garments made each year. That’s roughly 19 new pieces of clothing for every living person. There isn’t a brand (or consumer) who isn’t complicit in the problem, from luxury houses to high-street giants like H&M . And it isn’t just that the industry is making too many clothes; consumers are also disposing of them too quickly, often after just a few wears. One big step toward meaningfully reducing fashion’s footprint will be reeducating the consumer about buying fewer clothes, wearing them more, not throwing them out, and understanding what should happen to them when they’re really at the end of their life.

H&M proposed one solution last month: Looop , a machine in its Stockholm store that shreds old garments into new ones over the course of five hours. “The purpose of it is to engage our customers and help them understand their old garments have value,” explains Pascal Brun, H&M’s head of sustainability. “It’s also about making sure they experience the process of recycling, so it triggers behavioral change.” Looop is still in its early stages, so its capabilities are limited; it likely can’t recycle blended materials, which are difficult to separate, and zippers or hardware might pose a challenge. But Brun says they’re improving it day by day, so Looop will eventually be able to recycle many types of fibers and garments.

Instagram content

This content can also be viewed on the site it originates from.

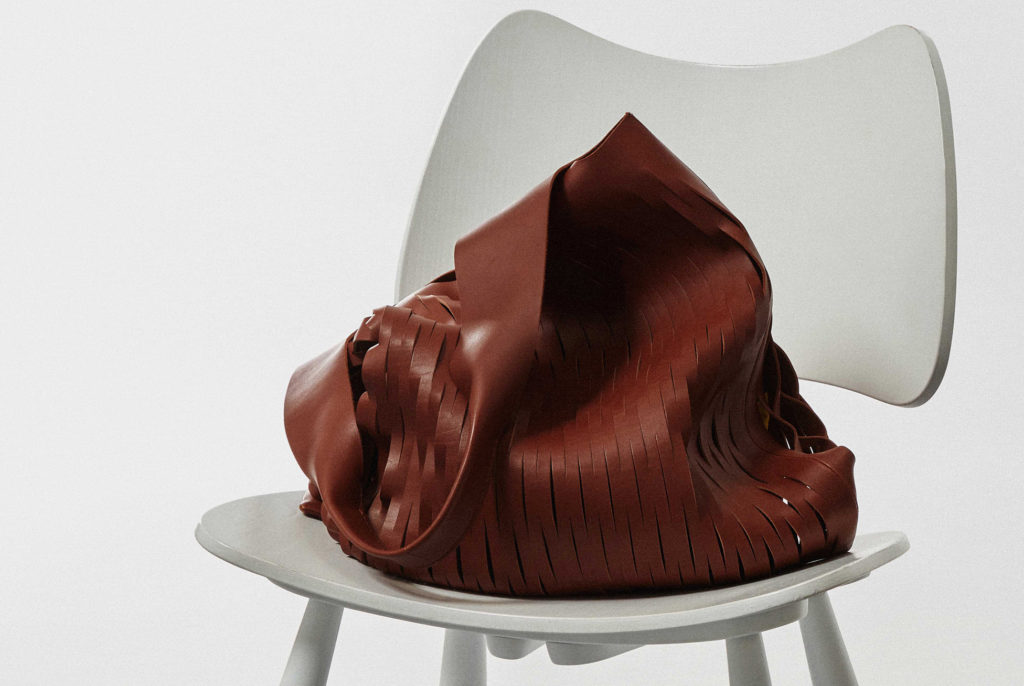

Today, H&M is taking another step toward becoming “fully circular” with its new Conscious Collection, which was made almost entirely of materials upcycled from waste. Brun pointed out that this will be the world launch for a few new fabrics, like AgraLoop BioFibre from Circular Systems, a natural fiber made from converted food crop waste (the company was the winner of H&M’s 2018 Global Change Awards). There’s also Vegea, a leather-like material made from byproducts of the winemaking process. This isn’t the first time H&M is making Vegea handbags, but creative advisor Ann-Sofie Johansson said its quality has gotten “better and better” over the past couple of years. Brun also called out WeAreSpinDye, a dyeing process that uses 90% fewer chemicals and 75% less water, and perhaps the collection’s most high-tech material: Made of Air, a plastic made from carbon emissions sequestered from the air and used for sunglasses. “It’s like mining the sky,” Brun adds.

“We’ve worked with materials made from waste before, but we wanted to focus on it more this season,” Johansson explains, adding that the design team was inspired by the 2019 Venice Biennale, titled May You Live in Interesting Times . “We need to see waste as a resource. It can become something beautiful, and it has value.”

The new Conscious Collection isn’t the only effort H&M is making in sustainability and circularity. Johansson explained that her team has started sketching in 3D, which gives them a better sense of how a garment will look and allows them to create samples only for the garments they plan to produce. “We’re looking at how we can use data to be more spot-on, and [cut] unnecessary garments,” she adds. “And we aren’t there yet, but I think the idea of producing on-demand is super-interesting.”

“One thing the pandemic has really taught us is that managing your stock is key,” Brun says. “I think on-demand production is where we’re going to see scale, because we can be closer to the demand.” In theory, on-demand production would make it possible to design and produce garments just before a consumer would buy them—as opposed to months in advance—so there’s a better understanding of what they’re actually in the mood for. “That would also help us be closer to the quantification [or number of garments], so we only produce what we sell,” he continues. “There is no business case for over-producing. It’s really about making sure we have an optimized production process, a flexible supply chain, and can use AI and data to quantify better.”

Of course, none of that matters if the clothes being created on-demand aren’t thoughtful and sustainable. “Everything we produce will need to be from a circular system,” Brun says. “Circularity is key for us, and it’s key for the industry going forward. I don’t see the industry being relevant and successful if it doesn’t become circular—the design of the product, the choice of the materials, the production processes, the customer use. How do we help our customer extend the life of their garments?”

Looop and waste-led design are small steps for now, but Brun and Johansson pointed out that a key role H&M plays with its Conscious Collections is helping technologies like AgraLoop and Made of Air scale, so they can eventually work with other brands. Those are exciting developments, but how we talk about them and market them is equally important. As New Standard Institute points out , some brands are already misusing the term circular in an effort to get customers to actually buy more. Real circularity will hinge on working together to transform our collective mindset so we can buy less, buy better, and understand the value in our clothes.

Vogue Daily

By signing up you agree to our User Agreement (including the class action waiver and arbitration provisions ), our Privacy Policy & Cookie Statement and to receive marketing and account-related emails from Vogue. You can unsubscribe at any time. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

WIRED x H&M | Investigating the machine reinventing recycling

In collaboration with WIRED, this new series shows how fashion is changing for the better. First up: innovaton lead at H&M Foundation Erik Bang on the world’s first Looop recycling system.

To tackle its contribution to the world’s most pressing environmental problems, fashion needs to change, including reinventing its old models of production. In collaboration with H&M, WIRED’s New Moves series focuses on those making positive steps to shift the industry’s approach to sustainability. From community champions to supply chain disruptors, these are people at the forefront of a movement for clothing circularity. “The fashion industry is relying on finite resources, it's over producing, over consuming and has a really big footprint on water, land, CO2 and biodiversity,” says Erik Bang, innovation lead at the H&M Foundation. Bang’s work seeks to remedy these flaws and has overseen the development of the groundbreaking Looop system. It’s the stuff of science fiction – an old garment goes in, a new garment comes out.

Using eight simple steps, the Looop system shreds an “end-of-life” piece of clothing and knits a new one from the fibres – using no water or dye. Its big breakthrough is that these eight machines have been miniaturised to fit into a standard shipping container, meaning it can be easily transported to showcase the whole process wherever it’s needed. “The point of Looop is to engage with consumers and influence their attitudes and behaviour,” explains Bang. “Textile is a valuable resource, not only to the planet, but also to this industry.”

“I encourage everybody to use their power as consumers to make better choices and to demand more from the companies they buy from.” ERIK BANG

No clothes should ever end up in the bin, yet every week, 13 million items of clothing enter UK landfills alone. Recycling is a vital step we can all take to make circular fashion work: without people ensuring their old garments re-enter the system, there won’t be materials with which to produce new ones. Real, impactful change at scale also requires every brand to use similar models, a fact not lost on Bang: “The H&M Foundation is a non-profit and our work is focused on bringing positive change for the entire fashion industry,” he says. “We collaborate, fund and share the solutions openly.” To help the whole industry become more circular and raise awareness of the potential of garment recycling, the technology behind Looop is set to be widely licensed to other companies.

“I encourage everybody to use their power as consumers to make better choices and to demand more from the companies they buy from,” Bang advocates. “It's not all done overnight… but you can do a whole lot more than you think.” This isn’t about acting perfectly, just better and constantly striving to improve. As crucial as it is, progress takes work and means all us getting on board. Follow New Moves for how you can make an impact.

Read the full story on WIRED

Become a member

Become a member — don’t miss out on deals, offers, discounts and bonus vouchers.

Wish your inbox was more stylish? No problem! Simply subscribe to our newsletter. Find out what's hot and happening in the world of fashion, beauty, and home decor. Plus, you'll get info on the latest membership rewards and events – straight to your inbox!

By clicking ‘Become a member’, I agree to the H&M Membership Terms and conditions .

To give you the full membership experience, we will process your personal data in accordance with the H&M's Privacy Notice .

- Founders Blog

- Arts & Leisure

- Celebrities

- Good Gardening

- Good Business

- Good Health

- GNN Podcast

- Become a Member

- Submit Your Own Good News

- Submit a News Link or Photo

- Gift Memberships

- Good News App

- Founder’s Blog

- Sign in / Join

Over Half of Americans Say Their Parent is Their Best Friend

Scottish Brothers Prepare for Record-breaking Fastest Row Across the Pacific Ocean in Boat They Designed

Man With Unyielding Depression Starts Picking Up Litter–And Helps Clear 13 Tons of Trash with Family and Strangers

Perfectly Preserved 250-Year-Old Cherries Found in George Washington’s Cellar at Mount Vernon

How To Love Yourself: 5 Ways to Let Go of the River Bank and Go With the Flow

Good Gardening Week 15: All About Spring Flowers—Plus Last Week’s Early Growing Images

GNN Founder Talks With BBC World Service About Positive News in the Media Landscape (Listen)

Good Gardening—A New Year: What Have You Got in the Ground?

All Your Nutrition in a Daily Drink That Also Feeds Hungry Kids

GNN Paperback Book: “And Now, The Good News”

A Daily Dose of Positive Affirmations–Right on Your Toes

‘Within Good’ – Reminder Bracelet

Holistic Patches Relieve Anxiety, Cramps, or Nausea – Without Drugs

Un Mapa te Permite Ver Como tu Hogar se ha Movido por el Continente en estos 750 Millones de Años

Las Playas han Visto un Incremento Enorme en Anidación de Tortugas Laúd Después de las Restricciones a los Turistas en Tailandia y Florida

Mira Mil Millones de Años de Movimiento de Placas Tectónicas Formando Nuestros Continentes en 40 Segundos

Un Pingüino Salta en un Bote para Evitar ser Comido por una Ballena Asesina – MIRA el Video

El Diseñador de Nueva Zelanda Crea un Ingenioso Tragaluz con Energía Solar que Desaliniza el Agua para Beber

H&m in-store recycling machine turns old clothes into new threads—a world first.

Fashion recycling, beyond simply reselling clothes, is a little behind other material recycling processes in terms of technology. But one of Europe’s largest and most popular labels, H&M, is establishing the world’s first in-store combination shredder and knitter of old clothes to tackle the problem head on.

Looop, the machine that shreds old clothes into component fibers, cleans and presses them into longer fibers, and weaves them into yarn before creating brand new garments, was developed by the Hong Kong Research Institute of Textiles and Apparel (HKRITA) in collaboration with the non-profit H&M Foundation.

“To fight climate change, we need to change fashion,” reads a statement on the fashion retailer’s website.

Indeed, analysis from the U.S. Environmental Protection Agency suggests that fashion waste may make up as much as 5% of landfill capacity, while also producing 10% of the nation’s total methane emissions.

Looop uses no additional dyes or water, relying instead solely on the color of the scrapped clothes. The process is completed on an assembly line of eight machines that are sold like a 40-foot long piece of furniture that can be easily shipped around the world in a standard shipping container.

RELATED: These Sunglasses Are Made From the First Ever Batch of Plastic Waste Recovered by the Ocean Cleanup Project

Looop is installed at Drottninggatan 56 in Stockholm, Sweden, but the technology is available for any fashion brands that want to employ it.

CHECK OUT: The Fashion Industry Has a Waste Problem: This Non-Profit With 2,000 Volunteers Is Helping Solve It

“It’s a reminder to treat all clothes as a resource. Nothing’s too tattered or torn to be recycled—and no clothes should ever end up in the trash.”

( WATCH the video of Looop in action below.)

SHARE The Green Fashion News With Friends on Social Media..

Wow! This cloth recycling machine is revolutionary and so necessary to help solve climate change.

Leave a Reply Cancel reply

You must be logged in to post a comment.

- Support GNN

- Privacy Policy

- Privacy Tools

H&M launches world's first in-store recycling system

- Circular economy

- Sustainable fashion

By Lucy Jones November 4th, 2020

The retailer's first garment-to-garment recycling system allows customers to watch as old garments are transformed into new ones.

Subscribe to the Australian Circular Economy Hub newsletter for the latest circular economy stories and updates on the ACE Hub.

H&M is one of the biggest players in the fast fashion industry. As such, the retailer has a major role to play when it comes to developing circular solutions for the billions of tonnes of textiles that are produced and disposed of every year . Garment-to-garment recycling is one such solution.

H&M has unveiled the world's first in-store clothing recycling system . Called 'Looop', the machine takes an old garment, shreds it down to fibres, spins new yarn and knits a new garment. A small quantity of sustainably sourced virgin material is added during this process to strengthen the fibre, but H&M is working on ways "to make this share as small as possible".

View this post on Instagram The glass box that’ll change fashion forever (well, our new in-store recycling system inside of it will). Learn more at hm.com/sustainability. #jointherecyclingrevolution #HM A post shared by H&M (@hm) on Oct 13, 2020 at 12:36am PDT

The Looop system diverts textile waste from landfill and reduces the amount of virgin material needed to create new garments, thereby reducing the environmental impacts that are associated with growing cotton .

"The system uses no water and no chemicals, thus having a significantly lower environmental impact than when producing garments from scratch," H&M explains in a statement .

The first Looop recycling facility opened on October 12 in H&M's Stockholm store. For 100 Swedish Krona (around $15 AUD), H&M loyalty club members can watch their old clothes be transformed into new ones before their eyes. Non-members can also recycle their clothes for an extra 50 Krona, that's a total of just over $23 AUD.

View this post on Instagram Circular solutions are the future. So, we’re bringing them to you! Read more at hm.com/sustainability. #jointherecyclingrevolution #HM A post shared by H&M (@hm) on Oct 14, 2020 at 4:30am PDT

As of 2019, 57 per cent of H&M's materials were either sustainably-sourced or recycled. The company hopes to bump that figure up to 100 per cent by 2030 through technological innovations like its Looop system.

“We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources. Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire,” H&M's Head of Sustainability, Pascal Brun, said .

Circular solutions require us to change our systems and our culture. By installing the Looop in its stores, H&M encourages customers to think about what happens to a piece of clothing at the end of its life. Taking the time to stop and think about how we might reuse and repurpose items before disposing of them will help us shift from a throwaway society to a circular one.

Interested in the circular economy? Planet Ark's Australian Circular Economy Hub (ACE Hub) officially launches on November 24 with an online event that will be live broadcast from the Sydney Opera House. Join us for a morning of talks from some of the brightest minds in the Australian and international Circular Economy space. Head here for more information and to secure your ticket.

Circular Economy News has been compiled using publicly available information. Planet Ark does not take responsibility for the accuracy of the original information and encourages readers to check the references before using this information for their own purposes.

Lucy started her career working as a writer and editor in print and digital publishing. She went on to create content for Australia's leading sustainable fashion platform while completing her Master of Cultural Studies. Lucy spends her downtime at the beach, crocheting and hanging out with her cat Larry. She believes words can change the world and is stoked to help Planet Ark spread the message of positive environmental change.

Related Stories

Silicon recovered from used solar panels holds huge potential value.

Pamela Jolly April 12th, 2023

Using technology to support the growth of smart circular cities

Pamela Jolly March 8th, 2023

Could farmed insects offer an efficient source of protein?

Pamela Jolly September 15th, 2022

Founding Partner

Official Sponsor

Stay informed on the latest Australian circular economy news and case studies. Subscribe to our newsletter

SUBSCRIBE TO OUR NEWSLETTER

Switch language:

H&M presents new Looop garment-to-garment recycling system

Swedish clothing-retail company H&M is introducing a garment-to-garment recycling system that helps transform old textiles into new ones.

- Share on Linkedin

- Share on Facebook

Swedish clothing-retail company H&M is introducing a garment-to-garment recycling system that helps transform old textiles into new ones.

Free Report

How are tech and delivery trends impacting the packaging of consumer goods.

- Data and insights into current consumer behavior

- Market outlook for e-commerce in consumer-packaged goods

- Strategic recommendations for packaging

- Insight into continuing concerns surrounding sustainability

You will receive an email shortly. Please check your inbox to download the Report.

Go deeper with GlobalData

Wider Opportunities for a Compostable Paper Bag - Packaging Seize+A...

Packaging industry mergers and acquisitions deals by top themes in ..., premium insights.

The gold standard of business intelligence.

Find out more

Related Company Profiles

H & m hennes & mauritz ab, the hong kong research institute of textiles and apparel limited.

By downloading this case study, you acknowledge that GlobalData may share your information with GlobalData and that your personal data will be used as described in their Privacy Policy

Tick here to opt out of curated industry news, reports, and event updates

Visit our Privacy Policy for more information about our services, how GlobalData may use, process and share your personal data, including information on your rights in respect of your personal data and how you can unsubscribe from future marketing communications. Our services are intended for corporate subscribers and you warrant that the email address submitted is your corporate email address.

Known as Looop, the container-sized machine promoted circularity in fashion and keeps unwanted garments from turning into waste.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

The move is part of the retailer’s bigger ambition to become fully circular and climate positive.

H&M plans to make all its materials either recycled or sourced in a more sustainable way by 2030.

Looop leverages a technique to dissemble and assemble old garments into new ones without using water and chemicals.

Cleaned garments are shredded into fibres and rolled into new yarn. This is then used in weaving new garments.

Additionally, the process requires the use of some sustainably sourced virgin materials.

H&M sustainability head Pascal Brun said: ”We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources.

“Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire.”

Looop is supported by the non-profit H&M Foundation along with The Hong Kong Research Institute of Textiles and Apparel (HKRITA) acting as research partner and Hong Kong-based yarn spinner Novetex Textiles.

The recycling system will be offered to customers in one of the retailer’s Drottninggatan stores in Stockholm on 12 October.

Sign up for our daily news round-up!

Give your business an edge with our leading industry insights.

More Relevant

Aldi UK initiates trial to eliminate banana plastic packaging

European parliament approves new packaging waste regulations, saputo dairy uk eliminates non-recyclable packaging, aldi introduces recycled plastic to its crisp packaging in uk, sign up to the newsletter: in brief, your corporate email address, i would also like to subscribe to:.

Inside Packaging : Packaging Gateway Focus (monthly)

Thematic Take (monthly)

I consent to Verdict Media Limited collecting my details provided via this form in accordance with Privacy Policy

Thank you for subscribing

View all newsletters from across the GlobalData Media network.

- BURDA LUXURY

- TRAVEL+LEISURE

- ARCHITECTURE+DESIGN

How H&M is turning old garments into new pieces with ‘Looop’

Looop by H&M is an initiative by the Swedish fast fashion giant to take their sustainability efforts up several notches.

We are thrilled that the fashion industry has been heading towards sustainability over the past few years, and it’s surprising to see how we can foster changes to our fashion products without compromising quality. It does not only mean ethical clothing feels good, but it also makes it a lot more affordable. Why grow more cotton when you can use an old cotton shirt to make a new one? That’s what Looop by H&M is all about: Circular fashion.

H&M is now offering customers in Sweden the possibility of transforming unwanted garments or textiles into new pieces in the most eco-friendly way. The world’s first-ever recycling system, Looop, like its moniker, helps closing the loop on fashion with this container-sized machine that is born to encourage customers to hold onto old textiles. The simple reason is that they are valuable and shouldn’t go to waste.

Looop opens to the public

Looop is now open to the public at one of the Drottninggatan stores in Stockholm. It is the first time a fashion retailer has presented its garment-to-garment recycling system to the public. Why so? When customers can see the change in front of them and can observe the whole process, it’s more likely to inspire them to love their garments for a longer time.

The launch of Looop isn’t just a glimpse of fashion’s future, but a reminder to treat all clothes as a resource. No clothes are too torn to be recycled or deserve to end up in the trash. For circular fashion to work, recycling is key.

How does Looop work?

The machine uses an 8-step technique that dissembles and assembles old garments into new ones. First, the garments are cleaned, then they are shredded into fibres and spun into new yarn, which eventually is knitted into new fashion materials. However, some sustainably-sourced virgin materials may be added to the process, but they try to keep it as little as possible. Looop does not use water or any chemicals, thus, it has a significantly lower environmental impact compared to when producing garments from scratch.

H&M has always strived towards making fast fashion a more sustainable industry. Back in 2013, H&M became the first fashion retailer with a global garment-collecting program and now with Looop, the fashion brand has definitely taken it to another level.

All images: Courtesy HnM

This story first appeared on Lifestyle Asia Bangkok

Alisha Pawa

Alisha is a passionate dancer and is always creating her own choreographies. She is a fan of rom-com novels, a coffee-drinker who loves tea, and is always on-the-go for her midnight chocolate cravings. She hopes to tick-off her never-ending bucket list one day by hosting her own travel show.

Yes, I agree to the Privacy Policy

Most Popular

Recommended for you

Step out in style with these classy tank tops

Most iconic moments from Victoria’s Secret fashion shows over the years

Indian couturiers changed the course of fashion one sustainable step at a time

Kriti Tula on conscious consumption through Doodlage, a made from waste label

Follow our daily snapshots at @lifestyleasiaindia

Subscribe to our newsletter to get the latest updates.

You’re all set

Thank you for your subscription.

H&M: Let's remake

84% of clothing ends up as landfill or in the incinerator.

It’s time to change the way we see our worn out and old clothing. Not as waste, but as a resource.

Give H&M customers a world-first opportunity; to turn their pre-loved clothing into a new garment, without the use of water or chemicals.

Housed in a giant glass box at H&M in central Stockholm, customers can now remake an old item of clothing with Looop, the name given to H&M’s garment-to-garment machine. Via an app, customers can configure their remake order and select from one of eight new, ready-to-wear designs. They then watch Looop remake their old garment into new, right in front of their eyes.

A striking red yarn installation weaves its way around the physical space, inviting customers to come up from the ground floor. Opposite the machine, eight giant screens display the end-to-end process behind it. Each depicts an individual step as a beautifully animated loop, which come to life as customers walk by. ASMR sound enriches each film to heighten the sensory experience. An accompanying website brings this revolutionary recycling system and its story to a global audience.

A fashion revolution begins, at the end.

During October 2020 at H&M Drottninggatan, Looop whirred into action and welcomed its first customers. From shirts to skirts and odd socks, old was remade into new, to start a revolution and to help change the way we see fashion, for the better.

"We are constantly exploring new technology and innovations to help transform the fashion industry… Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire." - Pascal Brun, Head of Sustainability at H&M

See more of the enriched case study on akqa.com.

AKQA is a design and innovation company that employs over 6,500 professionals across 20 countries. Named Digital Agency Global Network of the Year in Campaign’s 2023 Global Agency of the Year Awards, AKQA was also awarded the Cannes Lions Grand Prix for Digital Craft in 2023, and the Grand Prix for Design in 2021. In 2023, AKQA was recognised as a winner in Fast Company’s Innovation by Design Awards. AKQA also won Fast Company’s World Changing Ideas in 2021, and 2022 and led Gartner’s research into global marketing agencies in 2021.

- Digital Magazines

- Fashion Mannuscript

- Tech Tailor

- Accessories

- Cover Features

- Fashion News

- Fashion Tech

- Mann Report

- Mann About Town

- Advertising

- Privacy Policy

Recycling System ‘Looop’ Helps H&M Transform Unwanted Garments into New Fashion Favorites

Looop has opened to the public in one of H&M’s Drottninggatan stores in Stockholm . This is the first time this garment-to-garment recycling system is shown in store by a fashion retailer and H&M is proud to soon offer customers the opportunity to watch this container-sized machine recycle their old textiles into something new. This is part of a bigger plan – H&M’s ambition is to become fully circular and climate positive and it is working with many exciting projects to reach this goal. The company aims to innovate materials and processes while inspiring customers to keep their garments in use for as long as possible.

“We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources. Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire,” said Pascal Brun , head of sustainability at H&M.

Looop uses a technique that dissembles and assembles old garments into new ones. The garments are cleaned, shredded into fibres and spun into new yarn which is then knitted into new fashion finds. Some sustainably sourced virgin materials need to be added during the process, and we of course work to make this share as small as possible. The system uses no water and no chemicals, thus having a significantly lower environmental impact than when producing garments from scratch.

H&M wants to lead the change towards a sustainable fashion industry. In 2013, the company became the first fashion retailer with a global garment collecting program. Now, it is taking the next step with its garment-to-garment recycling system Looop. For 100 Swedish kronor, members of H&M’s loyalty club can watch Looop transform their old garment into a new favorite. For non-members the fee is 150 Swedish kronor. All proceeds go to projects related to research on materials. By 2030, the company aims for all of its materials to be either recycled or sourced in a more sustainable way, a figure that for 2019 was at 57%.

Looop is enabled by the non-profit H&M Foundation, together with research partner HKRITA (The Hong Kong Research Institute of Textiles and Apparel) and Hong Kong -based yarn spinner Novetex Textiles.

Fashion Designer Christian Siriano and Persil Laundry Detergent Launch 24-Hour Wardrobe Refresh Hotline on TikTok Live

Vuzix and Avegant Announce Strategic Partnership to Develop Full Color Optical Reference Design for AI-Enabled Consumer Smart Glasses

Target to Roll Out Transformative GenAI Technology to Its Store Team Members

Creator Commerce Platform Liketoknow.it Unveils New, Free Tool to Maximize Creator Earnings

Nordstrom Rack to Open New Location in Tarzana, California

H&M Launches ‘Looop’ Garment-To-Garment Recycling System In Stockholm

Fast fashion giant H&M has just debuted a new garment-to-garment recycling system called “Looop”, which enables the transformation of unwanted clothing into new textiles. It’s the latest move in a series of circularity-focused measures the company has made in recent months as it faces greater pressure from consumers over its environmental responsibility.

Launched on Monday (October 12), the new Looop system will offer customers the ability to see how its container-sized machine recycles their own textiles into something new. Displayed at one of H&M’s Drottninggatan stores in Stockholm , the company says that allowing customers to visualise a closed loop fashion approach will encourage more people to think about the value of their worn textiles.

“This is part of a bigger plan – our ambition is to become fully circular and climate positive and we are working with many exciting projects to reach this goal,” said the company in a press release. “We must innovate materials and processes while inspiring customers to keep their garments in use for as long as possible.”

Read: Q&A with Hanna Hallin of H&M Group’s sustainable fashion B2B platform Treadler

This is part of a bigger plan – our ambition is to become fully circular and climate positive and we are working with many exciting projects to reach this goal. H&M

Developed in partnership with The Hong Kong Research Institute of Textiles and Apparel (HKRITA) and Hong Kong-based yarn spinner Novetex, the Looop machine disassembles and assembles old garments. It first cleans and shreds them into fibres, before spinning them into brand new yarns that can be knitted into trendy new pieces – all without the use of water or toxic chemicals. While H&M admits that some new virgin materials have to be added into the mix, they pledge to “make this share as small as possible”.

“We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources,” said Pascal Brun, the head of sustainability at H&M. “Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire.”

Members of H&M’s loyalty programme will be able to try out Looop in stores for 100 SEK (US$11.33), while non-members will be charged 150 SEK (US$17). The fashion behemoth says that the proceeds will go towards material innovation and research to help the brand achieve its goal of 100% recycled or sustainably sourced materials by 2030.

We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources. Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire. Pascal Brun, Head of Sustainability at H&M

With statistics about the enormous waste and carbon footprint of the fashion industry making headlines in recent years, consumers have been putting greater pressure on brands to clean up their act. H&M, in particular, has launched a slew of measures in a bid to retain their market share, including debuting a rental, repair and recycling concept in their Stockholm flagship and partnering up with rental fashion subscription platform YCloset via its independent brand COS to offer rental in China .

In their Conscious Collection this year, H&M collaborated with Italian biomaterial startup Vegea to offer a number of handbags and shoes using a vegan leather made from the byproducts of wine. The fashion giant will also feature pieces made using Circulose fibre, which is created from recovered and recycled denim , which reduces textile and water waste.

All images courtesy of H&M.

Sally Ho is Green Queen's former resident writer and lead reporter. Passionate about the environment, social issues and health, she is always looking into the latest climate stories in Hong Kong and beyond. A long-time vegan, she also hopes to promote healthy and plant-based lifestyle choices in Asia. Sally has a background in Politics and International Relations from her studies at the London School of Economics and Political Science.

View all posts

Top Scientist To World: Second Trump Terms Means ‘Game Over’ For Climate

Health & Sustainability A Priority For Asian Consumers But Cost & Ease Remain Still A Barrier

UK Supreme Court Puts Future Fossil Fuel Projects in Jeopardy After Landmark Ruling

‘Mad Men’: UN Chief Called for A Ban on Fossil Fuel Advertising – But Media Companies Remain Mostly Silent

Hybrid Meat Startup SciFi Foods Shuts Down Amid Fundraising Challenges

Disney, Nestlé, easyJet Among Corporations That Invested in ‘Likely Junk’ Carbon Offsets

- Newsletter Sign Up

- Free Case Study: TiNDLE Foods Report 2024

- UPF & Plant-Based Meat FAQ Guide

- Plant Based News

- Alt Protein

- Cultivated Meat

- Climate Crisis

- Sustainable Fashion

- Zero Waste Life

- APAC Alt Protein Report 2022

- GQ Recipe Book

- Vegan Recipes

Recycling system ’Looop’ helps H&M transform unwanted garments into new fashion favourites

News article.

H&M is thrilled to soon offer customers in Sweden the possibility to transform unwanted garments into new fashion favourites with the help from its new garment-to-garment recycling system ‘Looop’. H&M is committed to closing the loop on fashion and this machine visualizes to customers that old textiles hold a value and should never go to waste.

Looop opens to the public in one of H&M’s Drottninggatan stores in Stockholm on October 12. This is the first time this garment-to-garment recycling system is shown in store by a fashion retailer and H&M is proud to soon offer customers the opportunity to watch this container-sized machine recycle their old textiles into something new. This is part of a bigger plan – H&M’s ambition is to become fully circular and climate positive and the retailer is working with many exciting projects to reach this goal. We must innovate materials and processes while inspiring customers to keep their garments in use for as long as possible.

“ We are constantly exploring new technology and innovations to help transform the fashion industry as we are working to reduce the dependency on virgin resources. Getting customers on board is key to achieve real change and we are so excited to see what Looop will inspire ”

Pascal Brun, Head of Sustainability at H&M

Looop uses a technique that dissembles and assembles old garments into new ones. The garments are cleaned, shredded into fibres and spun into new yarn which is then knitted into new fashion finds. Some sustainably sourced virgin materials need to be added during the process, and H&M of course work to make this share as small as possible. The system uses no water and no chemicals, thus having a significantly lower environmental impact than when producing garments from scratch.

H&M wants to lead the change towards a sustainable fashion industry. In 2013 H&M became the first fashion retailer with a global garment collecting program. Now, H&M is taking the next step with its garment-to-garment recycling system Looop. For 100 Swedish kronor, members of H&M’s loyalty club can use Looop to transform their old garment into a new favourite. For non-members the fee is 150 Swedish kronor. All proceeds go to projects related to research on materials. By 2030 H&M aims for all its materials to be either recycled or sourced in a more sustainable way, a figure that for 2019 was at 57%.

Looop is created by the non-profit H&M Foundation, together with research partner HKRITA (The Hong Kong Research Institute of Textiles and Apparel) and Hong Kong-based yarn spinner Novetex Textiles.

Collect, recirculate and recycle

COS launches Resell to prolong the lifespan of preloved clothes

H&M to be the first retailer to use Circulose

IMAGES

VIDEO

COMMENTS

In 2013 we became the first fashion retailer with a global garment collecting program. Now, we are taking the next step with our garment-to-garment recycling system Looop. For 100 Swedish kronor, members of our loyalty club can use Looop to transform their old garment into a new favourite. For non-members the fee is 150 Swedish kronor.

H&M has developed a machine that dissembles and assembles old clothes into new ones with 'looop' — the world's first in-store recycling system. 'looop' opened to the public in an H&M ...

CASE STUDY 5 - LOOOP BY H&M, GARMENT RECYCLING. APPROACHED BY: Users interested in recycling their garments. ... Looop is a recycling system that is a recent initiative by H&M, a Swedish ...

What is it? "Looop" is a new in-store recycling initiative being piloted by H&M. It is a garment-to-garment recycling system, designed to incentivize customers to recycle their old clothes (H&M 2020b, c). Although some sustainably sourced virgin materials must be added to strengthen the yarn, the system transforms old clothing into new ones ...

Looop - visualizing the value of textiles . Our newest eco-hero (read: game-changing recycling innovation) is Looop.Transforming old garments into fresh ones in only eight steps, Looop shows customers how something old can become something new - without the added environmental cost. The system recaptures valuable raw materials in recycled clothing and regenerates them back into fibres that ...

Update your wardrobe in a more conscious way. See how you can help us to transform old garments into new textile fibres.Read more at: www.hm.com/garment-coll...

H&M proposed one solution last month: Looop, a machine in its Stockholm store that shreds old garments into new ones over the course of five hours. "The purpose of it is to engage our customers ...

In collaboration with WIRED, this new series shows how fashion is changing for the better. First up: innovaton lead at H&M Foundation Erik Bang on the world's first Looop recycling system. To tackle its contribution to the world's most pressing environmental problems, fashion needs to change, including reinventing its old models of production.

But one of Europe's largest and most popular labels, H&M, is establishing the world's first in-store combination shredder and knitter of old clothes to tackle the problem head on. Looop, the ...

As described by H&M Thailand's CEO Looop "works by taking apart old garments and reassembling them into new apparel — in-store in a matter of a few hours — while producing zero waste.

H&M has unveiled the world's first in-store clothing recycling system. Called 'Looop', the machine takes an old garment, shreds it down to fibres, spins new yarn and knits a new garment. Called 'Looop', the machine takes an old garment, shreds it down to fibres, spins new yarn and knits a new garment.

Swedish clothing-retail company H&M is introducing a garment-to-garment recycling system that helps transform old textiles into new ones. PG. Menu ... By downloading this case study, ... Looop is supported by the non-profit H&M Foundation along with The Hong Kong Research Institute of Textiles and Apparel (HKRITA) acting as research partner and ...

H&M is now offering customers in Sweden the possibility of transforming unwanted garments or textiles into new pieces in the most eco-friendly way. The world's first-ever recycling system, Looop, like its moniker, helps closing the loop on fashion with this container-sized machine that is born to encourage customers to hold onto old textiles.

NEW YORK, Oct. 8, 2020 — We are thrilled to offer customers in Sweden soon the possibility to transform unwanted garments into new fashion favorites with the help of our new garment-to-garment recycling system 'Looop.' We are committed to closing the loop on fashion, and this machine visualizes to customers that old textiles hold value … Continue reading "Recycling System 'Looop ...

H&M Group was the first fashion company to launch a garment collecting initiative worldwide in 2013 and has, through its investment arm H&M CO:LAB, invested in companies that develop technologies to enable textile recycling. With the creation of this standalone joint venture, H&M Group is participating more directly in developing the ...

Housed in a giant glass box at H&M in central Stockholm, customers can now remake an old item of clothing with Looop, the name given to H&M's garment-to-garment machine. Via an app, customers can configure their remake order and select from one of eight new, ready-to-wear designs. ... M See more of the enriched case study on akqa.com. ...

Building a circular ecosystem is a continuous journey with many interdependencies both within and outside H&M Group. We are aligning supply and demand, and increasing material efficiency. We invest in AI and tech tools for improved planning and accuracy, and customer centricity. We have developed circular design guidelines and are increasing ...

H&M is one of the worst offenders in the world of fast fashion, but they are also a leading innovator in taking responsibility for their earth-threatening, consume-at-all-costs philosophy. Bloomberg reported that in 2018 H&M had $4.3 billion worth of unsellable inventory, as profits plunged to the lowest level since 2005.

In 2013, the company became the first fashion retailer with a global garment collecting program. Now, it is taking the next step with its garment-to-garment recycling system Looop. For 100 Swedish kronor, members of H&M's loyalty club can watch Looop transform their old garment into a new favorite. For non-members the fee is 150 Swedish kronor.

The brand created 'H&M Looop Isle' on Animal Crossing, paying well-known social media influencers and Twitch streamers to visit the island and tell their Instagram followers all about H&M's circular fashion plans. Instagram search for #looopit in April 2021 — filled with #ads from H&M and all your favourite influencers.

3 Mins Read. Fast fashion giant H&M has just debuted a new garment-to-garment recycling system called "Looop", which enables the transformation of unwanted clothing into new textiles. It's the latest move in a series of circularity-focused measures the company has made in recent months as it faces greater pressure from consumers over its environmental responsibility.

In 2013 H&M became the first fashion retailer with a global garment collecting program. Now, H&M is taking the next step with its garment-to-garment recycling system Looop. For 100 Swedish kronor, members of H&M's loyalty club can use Looop to transform their old garment into a new favourite. For non-members the fee is 150 Swedish kronor.

The introduction of Looop to one of its Stockholm stores is one way that the conglomerate is trying to engage and educate consumers about circular fashion.