Lean 5S Methodology Overview

5S is not complicated to understand or even to practice. The key is to do it everyday, with everyone participating, and in every place within your organization.

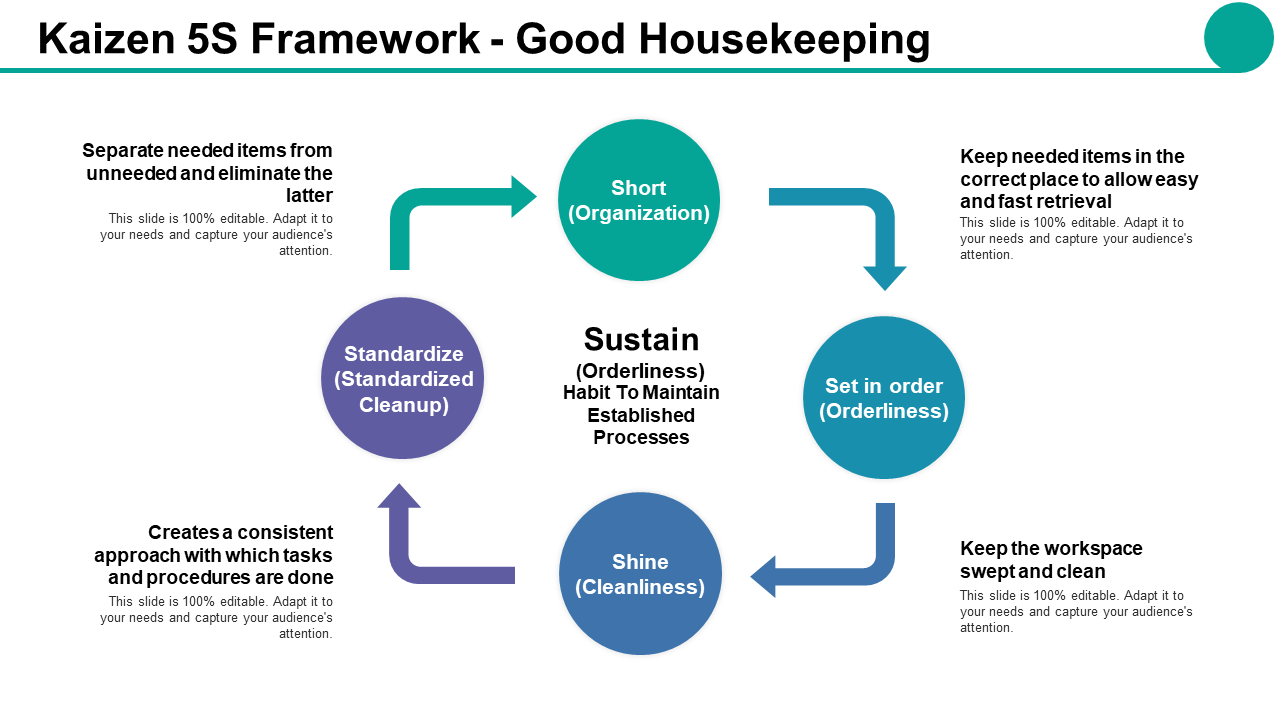

In this way, 5S connects deeply with the continuous improvement philosophy of kaizen .

Watch our introductory video for a six-minute overview of 5S.

Trial our Course: 5S Productivity

Start a 30-day trial of the Lean Smarts Academy and preview our 5S Productivity course.

A History of 5S Programs | Origins of 5S

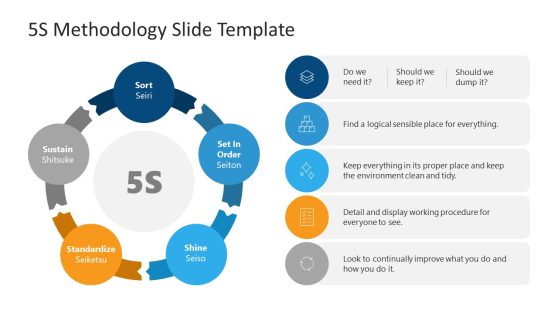

The modern version of 5S is an English adaptation of an original program that has been popular in Japan for decades. There are five S’s in 5S due to the alliteration of the Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke .

Each of the five Japanese words have added meaning in Japanese culture that is difficult to capture in English translations. This is perhaps a reason for some of the confusion around the English equivalents, especially with “standardize” and “sustain.” ( See Michel Baudin’s explanation ).

Henry Ford’s CANDO Program

Some people believe that the Japanese program was inspired by an original five-step program promoted by Henry Ford called CANDO.

- Cleaning up

- Ongoing improvement

Variations of the 5S Words

Some of the imperfections of translating five Japanese words into English have led to variations of the 5S terms.

For example, “sweep” is commonly interchanged with “shine,” and “straighten” is commonly interchanged with “set in order.”

Regardless of the words that are used, we maintain that the function of these terms matters more than the title you give to them! How much does it matter what words you use as long as you: 1) still reap the intended benefits of 5S, and 2) can understand each other when speaking about 5S?

Reasons for Starting Lean with 5S

It is commonly expressed by consultants and lean literature that “if you can’t do 5S, you probably don’t have the discipline to do anything else.”

There is some merit to this! 5S is a rite-of-passage for organizations learning lean.

Aside from the fact that 5S programs are a common and easy introduction to lean practices, there are other good reasons for adopting 5S methodology early in your lean journey.

#1 It flushes out old mindsets and culture

While it is true that 5S leads to a physical transformation of your workplace, it also inspires an invisible transformation in the thinking and behavior of everyone working there.

When sorting and removing junk that doesn’t belong, organizing what remains so it’s easy to use, and taking pride in your work areas with regular cleaning, you also dislodge old beliefs, excuses, behaviors, and mindsets.

#2 You have to engage everyone

5S must involve every person in the organization for it to succeed. You have to engage everyone!

This is to your advantage in developing a lean culture of kaizen and continuous improvement.

If your intent is truly to develop and grow people (as it should be!), you can develop a kaizen culture of improvement “everyone, every day, everywhere” with 5S!

#3 It’s cheap and easy to do

You need almost no upfront investment of money to get started with 5S. All you need is some knowledge and time.

While you can purchase 5S supplies to support your efforts, many organizations discover a wealth of reusable materials, equipment, tools, and supplies already inside the building the moment they begin to 5S and sort.

In the majority of situations, you’re only limited by your creativity–not your wallet!

It’s also easy to do. In fact, in 30-60 minutes our 5S Productivity training course can prepare anyone with the skill and confidence needed to get started now.

#4 It’s the basics; it never goes away!

No matter what else you do that’s “lean,” you will never outgrow your need to 5S on a daily basis.

Entropy never takes a break causing mess, confusion, and equipment breakdown. Therefore, you’ll forever need to sort, set in order, and shine at your organization!

#5 It creates peace of mind and clarity

An orderly and clean work environment does help to reduce stress and confusion in the workplace.

The stress and confusion in many organizations is largely due to the disarray of information, tools, and materials. The clutter and clogging of a production floor creates needless searching, movement, transportation, defects, and other wastes.

It’s not necessary and should not be considered “normal” to struggle and stress at work. 5S methodology is a major first step for organizations to get control back of their environment.

The Meaning of Sort

5S methodology begins with the simple practice of sorting out all the unneeded items in a workplace.

Get rid of all the junk and clutter:

- extra inventory

- broken equipment

- extra tools

- outdated signage

- unfinished work

- leftover materials

5S Training Presentations

5s pptx and 5s pdf downloads.

If you want to learn all about 5S then the following 5S presentations in ppt (PowerPoint) format and PDF format are available to you for free download. Please note that these 5S Training presentation files are protected by copyright and are to be downloaded for your own personal use only.

- Any commercial use of these 5S presentations and the content therein is prohibited without prior permission. Requests for permission to use can be made through the contact page of http://leanmanufacturingtools.org/contact-page/

- These presentations are for personal use only and cannot be reproduced or circulated by anyone other than www.leanmanufacturingtools.org

- Content may be quoted or reproduced for private and educational assignments as long as a proper citation is given referring to leanmanufacturingtools.org

- The information within these presentations and website are for information purposes only and any action taken is at your own risk.

These lean manufacturing training presentations are organized so that you can tackle the ideas behind 5S one step at a time, for your own education or even to train others within your own organization. Breaking them up into bite sized chunks allows you to learn or teach 5S in manageable and understandable sections even if your available time is limited.

These presentations can be use in conjunction with the following pages here;

Running your own 5S program

How to approach 5S training

Run your own 5S training course in house

5S Training PowerPoint (pptx) Presentations;

Basic introduction to 5s presentations;.

What is 5S – Learn what is 5S.

Benefits of 5S – Learn the benefits of implementing 5S within your organization.

Presentations Detailing Each 5S Stage;

5S Seiri Sort – The first stage of implementing 5S.

5S Seiton Set in Order – The second stage of implementing 5S

5S Seiso Shine – The third stage of implementing 5S

5S Seiketsu Standardize – The forth stage of implementing 5S

5S Shitsuke Sustain – The fifth and final stage of 5S implementation

Lean 6S ppt Training Presentation;

6S – How does 6S differ from 5S and why?

Presentations Supporting Your 5S Training;

5S Red Tag – Learn how to use 5S Red Tags

Runners Repeaters Strangers – Learn how to apply RRS techniques when implementing 5S

Presentation Detailing How to Plan and Conduct Your 5S Implementation;

5S Program Implementation – Step by step guide to implementing 5S within your operations.

5S Training Exercise Presentation;

Training Exercise – 5S Paper exercise; a quick and simple training exercise designed for 5S which will demonstrate the simplicity and effectiveness of 5S.

5S Training PDF Files for Download;

All of the above 5S presentations are also available as 5S PDF files for download;

What is 5S Presentation

Benefits of 5S

5S Seiri or Sort – First stage of 5S

5S Seiton or Set In Order – Second stage of 5S

5S Seiso or Shine – Third stage of 5S

5S Seiketsu or Standardize – Forth stage of 5S

5S Shitsuke or Sustain – Final stage of 5S

5S Runners Repeaters and Strangers

Implementing 5S Program

5S Training Exercise

Should you require a personalized or editable version of these 5S PowerPoint presentations or 5S PDF files just contact the author through the contact page here; Leanmanufacturingtools.org contact page .

Suggestions for improvements or additions to the above 5S training presentations are welcomed.

Related posts:

- Lean Training, Coaching, and Presentations

- Free Lean Presentations

- 5S Training

Post navigation

13 comments for “ 5s training presentations ”.

i want fully details of 5s

Hi K.P. Feel free to download any of the presentations and PDF files here to provide you with all of the info that you need on 5S.

PLEASE BRIEF ON 5S / 6S , LATEST VERSION. 6 SIGMA.

let me know more about it

5’S means house keeping in our Indian language . each and every letters are starting from “S” letters .so,called 1s,2s 3s,4s&5s . on japan language India language 1) seiri -short out 2)seiton -set in order 3) seiso -shine 4)seiketshu -standardization 5)sitsuke -sustain short out -1)material segregated require /un require.if, unwanted material will be put red tag and remove from our working area 2)if,required material then will be put yellow tag .3)if,not required but,well material then will be through to red zone area . Set in Order – required material will be keep by rack /cup board /shelves etc 3)shine identified material clean daily /weekly/yearly 4)standardization this 1s,2s,3s will be keep regularly. 5)sustain this work will be make habit.

How can I download the course?

Samer, Just click on the links to download each of the 5S presentations.

hi Earley i would like develop on these 5 s principles using my domain knowledge in the Oil and Gas upstream sector and would like to conduct workshops to our fraternity please confirm if you have any objection regards Damodaran M

I would like to use this training for our maintenance department at Westrock Solvay ny.

I have “before” pictures ready and will have “after” pictures as well.

Would you like to see our ,ppt when complete?

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

CAPTCHA Code *

What Is the 5S Methodology?

The 5S methodology is best summarized by the philosophy, “a place for everything and everything in its place.”

You may have heard of “KonMari,” a home organization system invented by Marie Kondo. The KonMari method transforms cluttered homes into tidy and simplified living spaces. The 5S principles are similar to KonMari. However, saying that 5S is just about tidying is like saying successful manufacturing is just about speed - there is much more depth. So, let’s explore the true intent and meaning of 5S.

5S Japanese Words

5S originated as 5 Japanese words:

5S Meaning in English

In English, these 5S meanings are:

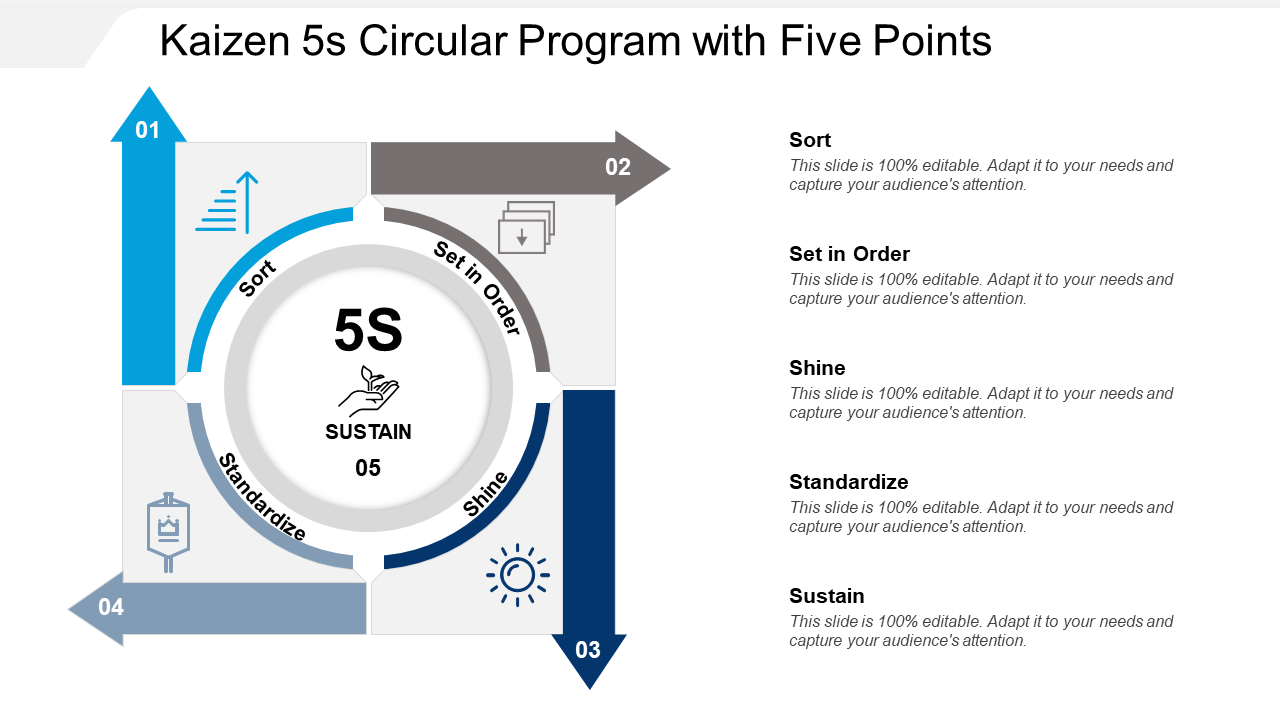

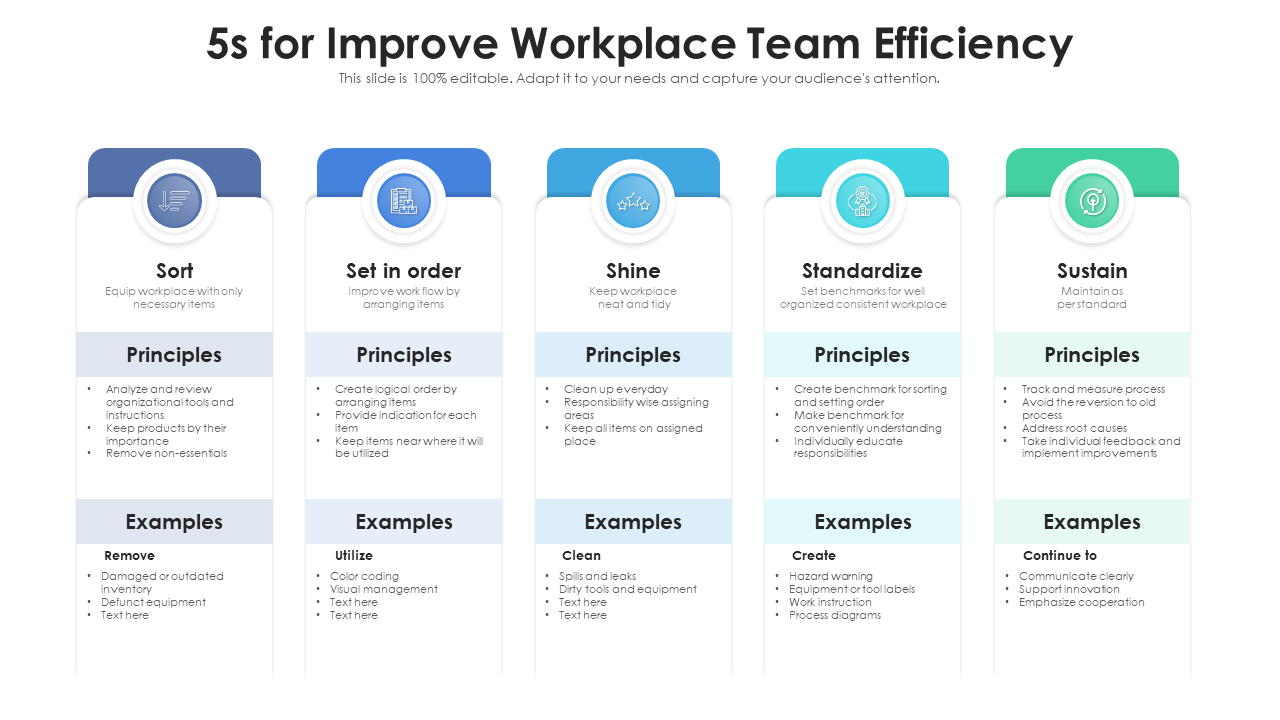

- Sort (Seiri): Eliminate that which is not needed.

- Straighten (Seiton): Organize what remains after sorting.

- Shine (Seisou): Clean and inspect the work area.

- Standardize (Seiketsu): Write standards for 5S.

- Sustain (Shitsuke): Consistently apply the 5S standards.

At their core, these 5S activities build the discipline needed for substantial and continuous improvement by creating (and sustaining) efficient and effective work areas.

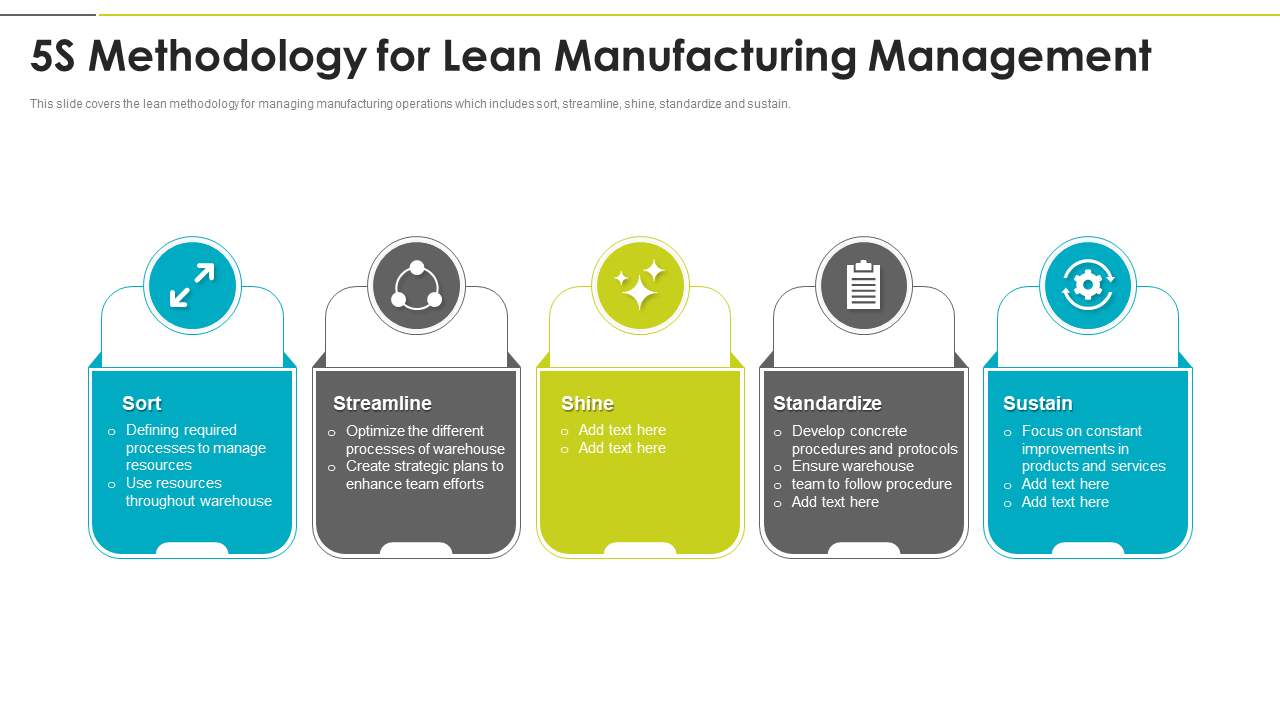

Why Is 5S Important in Manufacturing?

While 5S was first developed in the context of the automotive industry, it is now widely considered an essential step for any lean manufacturing program, regardless of industry.

Embedding 5S as part of daily tasks within your company means much more than improved organization, sustained cleaning routines, and efficient activity flows. By using the 5S methodology, operators are encouraged to improve their overall work environment and reduce muda or waste .

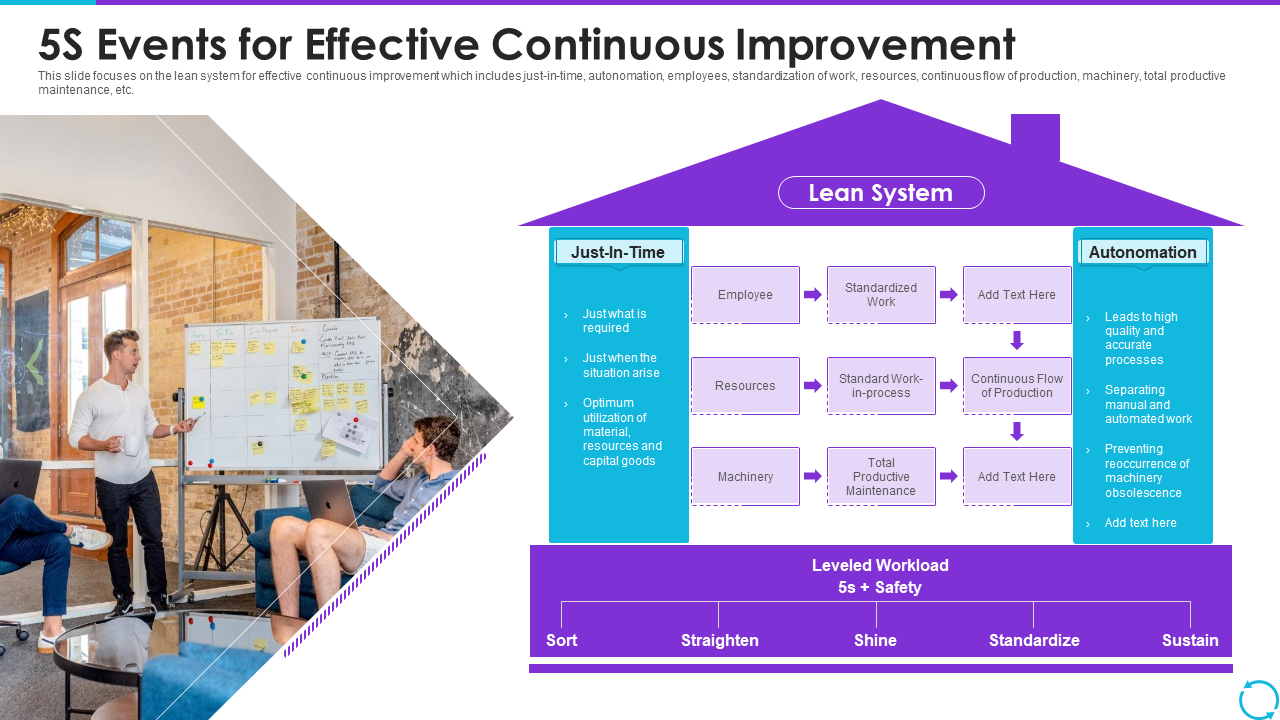

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS) . 5S also creates a stable platform from which Kaizen activities can be launched.

The bottom line - 5S is a low-investment, high-impact lean manufacturing tool that is predicated on people. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

What Are the 5 Benefits of a 5S System?

The key benefits of a 5S system include:

- Creating space within your facility by removing unnecessary tools and equipment

- Reducing waste from unnecessary motion by organizing the workspace

- Reducing downtime and improving quality by consistently maintaining equipment

- Engaging operators by granting them more responsibility for their work environment

- Creating a safer work environment by ensuring it is clean and well-maintained

Now that you have a better understanding of why 5S is important and how it can benefit your manufacturing operations, let’s learn more about each of the 5S steps.

Sort (Seiri)

What is sort.

The Sort step separates items in your workspace that you know you need from items that you do not or may not need. Move the latter to a “red tag” holding area.

Why Do You Need Sort?

Sort enables you to have a more productive workspace by removing unneeded clutter (and eliminating distractions). It also is a first step towards opening up space that can be used for other things.

How Do You Implement Sort?

Separate necessary items (e.g., tools, parts, and materials) from unnecessary items. We recommend sorting items into four categories:

- Items needed in this work area. These are items you know that you regularly use in the context of this work area and thus will stay in this work area.

- Items needed in another work area. These are typically misplaced items. If an item is used in another work area, “sort” it into that area by delivering it to the team member responsible for that work area.

- Items you may need. For items you are unsure about, use the 5S “red tag” system. Mark such items with red tags, which at a minimum, should include the name of who tagged the item, why it is thought to no longer be needed, a proposed review date, and the name of the manager who must approve of disposal. Move the item to a red tag holding area, which should be organized by review month to make it easy to manage the area.

- Items you do not need. These are items that you are 100% confident are not needed. They should be immediately discarded, recycled, or donated, or sold if in good condition.

What Are Some Examples of Sort?

- Remove waste (or muda) from your workspace.

- Discard broken or old parts using 5S red tags.

- Responsibly recycle materials and papers.

- Separate everyday tools from special-case tools.

- Avoid overfilling your workspace with excess materials.

- Create an overflow area outside of the workspace for duplicate materials, tools, and parts.

Straighten (Seiton)

What is straighten.

The Straighten step thoroughly organizes the items that remain after sorting, making frequently used items easily accessible and providing every item a clear and easy-to-find home.

Why Do You Need to Straighten?

Straighten enables every item to have a specific home where it can be easily found and to which it can be easily returned. It reduces the waste from excess motion, as items are placed in more ergonomic locations. It is also the second step on the path to opening up space that can be used strategically toward the goal of improving production.

How Do You Implement Straighten?

After you’ve sorted items, it’s time to decide how you want to organize them. We recommend the following methodology:

- Provide easy access to frequently used items. The key to reducing waste from excess motion is to place frequently used items within easy reach.

- Group like items. Group the remaining items into logical categories and brainstorm the best way to organize and store each of these categories.

- Utilize visual designs. For each group, decide on the best way to make it clear when an item is missing or misplaced. A classic example is creating a shadow board for tools.

- Use containers. If it is appropriate for the type of item, consider organizing it within a container.

- Unleash the labeler. If an item is too big to put into a container, consider giving it a frame and putting a label on the item in addition to the frame.

- Be agile . Your initial straighten pass will likely deliver a significant improvement - but you are also likely to overlook some potential improvements. Plan a 5S team meeting with a focus on straightening at the one and two week points, and brainstorm further improvements as part of your initial implementation.

What Are Some Examples of Straighten?

- Give every item a distinct “home.”

- Use color as a way of organizing and creating meaning.

- Integrate shadow boards and other visual indicators into the plant floor.

- Dedicate a surface or area entirely to shadow boxes and tool storage.

- Dedicate another surface or area entirely to working.

Shine (Seisou)

What is shine.

The Shine step elevates the work area by ensuring thoroughly cleaned and inspected tools, equipment, and other items. It also can include routine maintenance on equipment, which is one of the ways it flows directly into TPM .

Why Do You Need to Shine?

Shine creates a work environment that engages and empowers operators by giving them more responsibility and agency over their work area. It also helps them to identify problems before they interfere with production. For example, in a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, etc.

How Do You Implement Shine?

After you’ve straightened items, it’s time to elevate the work area by cleaning, inspecting, and in some cases, performing routine maintenance. We recommend the following:

- Grab the metaphorical spray bottle. Using appropriate cleaners and cleaning tools, make the work area sparkle. With every sweep, mop, brush, wipe, wash, and wax, strive to return your workspace to its former glory. Be Miyagi.

- Find the source. The guiding principle of this 5S step is “clean to understand”. If there are any signs of leaks, spills, or unexpected debris, strive to understand the source. It is likely an early warning of a future problem.

- Inspect. After cleaning each item, take a moment to look it over and examine its condition. Does it need updating, maintenance, or repair?

What Are Some Examples of Shine?

- Wipe down equipment.

- Examine the wear of your tools.

- Disassemble larger objects to inspect the state of their parts.

- Investigate a recurring unclean spot or mess.

- Make sure to follow proper cleaning procedures to prevent damage to equipment.

Standardize (Seiketsu)

What is standardize.

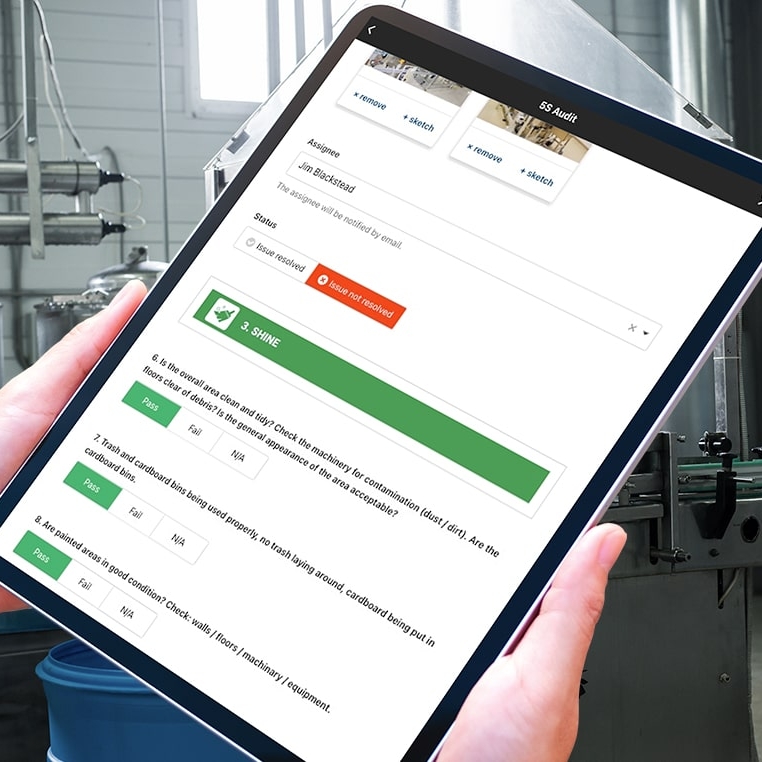

The Standardize step is a bridge between the first three 5S steps (Sort, Straighten, Shine) and the last step (Sustain). In this step, your goal is to capture best practices for 5S as standardized work for your team.

Why Do You Need to Standardize?

Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities.

How Do You Implement Standardize?

It’s time to make sure all your hard work continues to pay dividends into the future. Set expectations for the future with a documented 5S process. To do so, we recommend that you:

- Document in pairs. Have one team member walk through each 5S task as another team member documents it to ensure nothing important is missed.

- Capture the essence. We are huge proponents of simplicity (and agile ). Capture the essence of each task and no more. Otherwise, your documentation will be difficult to maintain.

- Prefer checklists. Checklists feel easy. Short checklists feel even easier. A great format is providing a name for each task that serves as a quick reminder and a more detailed description for training.

- Organize to simplify. Organize your checklists by role, by shift, and by frequency (daily, weekly, monthly). This will make the 5S process much less intimidating to your team.

What Are Some Examples of Standardize?

- Write down your 5S practices.

- Create “implementation” checklists and “audit” checklists.

- Create “kits” that contain the materials needed to perform a specific task.

- Use photos and other simple visuals as part of your training materials.

- Build a schedule for tasks.

Sustain (Shitsuke)

What is sustain.

The Sustain step ensures that 5S is applied on an ongoing basis. It transforms your standardized 5S processes into regularly completed tasks.

Why Do You Need to Sustain?

Iterative 5S processes lock in your gains and ensure further and continued progress.

How Do You Implement Sustain?

Once you’ve standardized, it’s time to continually act upon those standards. We recommend you:

- Create a schedule. Embed 5S practices as scheduled tasks (by role, shift, and frequency).

- Teach through demonstration. Instruct employees on how to conduct 5S tasks through demonstration and training. Showing employees what is expected of them will prepare them to conduct tasks on their own.

- Supervise to solo. After initial 5S training for employees, gently supervise while they continue to form habits. It is easy to make mistakes or fall off course, so patiently and helpfully offer corrections when needed.

- Adapt as necessary. When giving or receiving feedback on tasks, see where changes can be made to make the tasks easier and more efficient. Standardized work is intended to be living documentation.

What Are Some Examples of Sustain?

- Hold a demonstration meeting to explain complex or multi-step processes.

- Perform periodic check-ins after initial training.

- Teach employees to run 5S audits.

- Respond to mistakes with additional training.

- Encourage supervisors and operators to communicate openly and constructively to find ways to improve your 5S implementation.

- Set quarterly audit reminders for reviewing the red tag holding area.

The Bonus S of 5S

Now that you know how to implement each step in the 5S methodology and foster a culture of continuous improvement in your factory, you are ready to learn the bonus S: Safety!

5S is meant to help you improve productivity in your factory, but it is also meant to help create a safe, positive work environment for your team. While preventing workplace injuries is very important - also important is that 5S will make your plant a great place to work. Everyone enjoys a safe, clean, and logically laid out work environment, and it will motivate your employees, leading to better results on the plant floor.

How Does Each of the 5S Steps Contribute to Safety?

- Sort removes items from the plant floor, creating more space. Of course, this space can be used to hold new tools and equipment, but it can also be used to create larger aisles and more open spaces in the factory, removing tripping hazards. Even something as simple as decluttering drawers can prevent injuries (e.g., accidental encounters with a sharp object when rummaging for the tool you need).

- Straighten gives every item a logical home near the location where operators will use it. This prevents operators from rushing around looking for what they need, avoiding chaos on the plant floor that could cause safety hazards. For example, operators could slip, trip, or bump into one another if they have to constantly hurry around looking for tools.

- Shine cleans the workspace and maintains equipment. This prevents leaks or spills from leaving slick spots on the floor and ensures operators have functioning tools so they don’t have to dangerously jerry-rig solutions.

- Standardize makes clear to everyone what needs to be done and to whom each task belongs so tasks are completed on a regular basis. Confusion regarding ownership of responsibilities can cause important jobs to be missed. For example, equipment that is not consistently maintained will likely create safety concerns.

- Sustain ensures your initial 5S efforts are not in vain, keeping your staff happy and on top of any new safety concerns as they arise. One of the most dangerous things you can have in your factory is unmotivated employees who do not care about maintaining the condition of their workplace. Ensuring their efforts to implement a 5S program are recognized and sustained will provide continued motivation.

Overall, the 5S process is worth the initial organizational work for the rewards in safety, production improvement, and employee motivation.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.

- Lean Manufacturing News

- Lean Opinion

5S Methodology: The Ultimate Guide to Workplace Organization

The 5S methodology is an organization system for workplaces used in manufacturing and other industries for decades to improve efficiency, reduce waste, and increase safety. It is also considered one foundational pillar of having a Lean company.

The 5S’s stand for the procedures that include Sort, Set in Order, Shine, Standardize, and Sustain, and each S represents a different step in the process.

In this article, we’ll provide a comprehensive guide to the 5S methodology, including what it is, how it works, and how to implement it in your workplace. Whether in manufacturing, healthcare, or any other industry, the 5S methodology can help you create a more organized, efficient, and productive workspace.

Understanding the 5S Methodology

This involves going through all the items in a workspace and separating them into three categories: keep, discard, or relocate. The goal is to eliminate clutter and unnecessary items.

Set in Order

Once the workspace has been sorted, the next step is to organize the remaining items logically and efficiently. This might involve creating storage solutions , labelling items, or establishing a system for inventory management.

This involves cleaning and maintaining the workspace to ensure it is safe and functional. This might involve regular cleaning, maintenance of equipment, or establishing a cleaning schedule.

Standardize

In this step, the goal is to establish consistent procedures and practices throughout the workspace. This might involve creating standard operating procedures, establishing guidelines for how work should be done, or implementing quality control measures.

The final step in the 5S methodology ensures that the improvements made during the first four steps are sustained over the long term. This might involve ongoing training, regular audits, or assigning responsibilities for maintaining the workspace.

By following the 5S methodology, organizations can create a more organized, efficient, and productive workspace. The following section will provide a detailed guide to implementing the 5S methods in your workplace.

Implementation of the 5S Methodology

Implementing the 5S methodology in your work involves a series of steps, each building upon the previous one. Here is a step-by-step guide to implementing the 5S method.

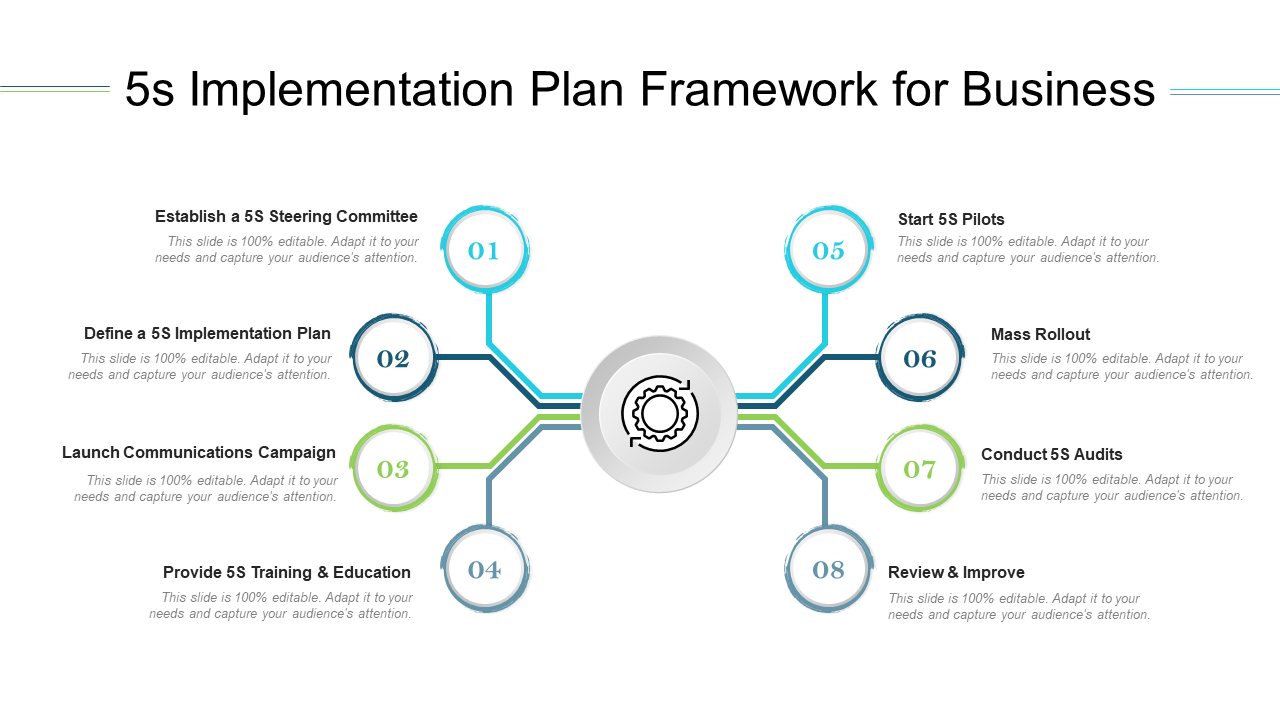

Establish a Team

The first step in implementing the 5S methodology is establishing a team responsible for overseeing the process. This team should include representatives from all levels of the organization. Also, it must be led by someone with experience with the 5S methodology.

Conduct a Workplace Assessment

The next step is to assess the current state of the workplace. This might involve observing work processes, interviewing employees, or reviewing documents and records. The goal is to identify areas where improvements can be made.

Sort And Organize

Once the assessment is complete, the team should begin sorting and organizing the workplace. This involves going through all the items in the workspace and separating them into three categories: keep, discard, or relocate. The team should then organize the remaining items in an orderly fashion.

Clean And Maintain

With the workspace sorted and organized, the next step is to clean and maintain it. This might involve establishing a cleaning schedule, maintaining equipment, or implementing a preventive maintenance program.

The team should establish consistent procedures and practices throughout the workspace in this step. This might involve creating standard operating procedures, establishing guidelines for how work should be done, or implementing quality control measures.

The final step is to ensure that the improvements made during the first five steps are sustained over the long term. This might involve ongoing training, regular audits, or assigning responsibilities for maintaining the workspace.

By following these six steps, organizations can successfully implement the 5S methodology and create a more organized, efficient, and productive workspace.

Despite having the right steps in place, there is still the roadblock of getting everyone involved. Let’s take a look at several tips for getting the employees and management to buy-in and support these steps.

Additional Resources for Learning More About the 5S Methodology

Many resources are available online and offline if you’re interested in learning more about the 5S methodology. Here are a few places to start.

Many books provide a detailed overview of the 5S methodology and how to implement it. Some popular titles include “5S for Operators: 5 Pillars of the Visual Workplace” by Hiroyuki Hirano and “5S for Service Organizations and Offices: A Lean Look at Improvements” by Debashis Sarkar.

Online Courses

Many organizations offer online courses and training programs focused on the 5S methodology. These can be a great way to understand the method better and learn how to implement it in your workplace.

Conferences And Workshops

Attending conferences and workshops focused on the 5S methodology can be a great way to learn from experts and network with other professionals interested in workplace organization and efficiency.

Consult With Experts

If you struggle to implement the 5S methodology in your workplace, consider consulting with an expert. Many consultants and consulting firms specialize in workplace organization and efficiency, and they can provide valuable guidance and support.

By taking advantage of these resources, you can learn more about the 5S methodology and how to implement it in your workplace.

Improving Organization, Efficiency, And Safety

The 5S methodology is a powerful tool for improving workplace organization, efficiency, and safety. By following the five steps of the 5S method – sort, organize, clean, standardize, and sustain – organizations can create a more productive and enjoyable work environment. The beautiful thing is that these steps can also be applied at home.

However, implementing the 5S methodology requires buy-in from employees and management, and ongoing support is needed to ensure the improvements are sustained over time.

If you want to implement the 5S methodology, start by conducting a workplace assessment and forming a team to oversee the process. Involve employees in the process, communicate the benefits, and provide ongoing support to ensure the improvements are sustained over the long term.

Remember that implementing the 5S methodology is an ongoing process requiring a commitment to continuous improvement. By staying focused on the end goal – a more organized, efficient, and productive workplace – and following the steps outlined in this article, you can successfully implement the 5S methodology and enjoy its many benefits.

Related Posts

Lean Project Management Tools: What You Need to Know

A Complete Guide to Lean Manufacturing – Lean Factories

Hitachi Reopens Factory after Major Refurbishment

HIPAA FINES: 10 Common HIPAA Violations to Avoid

Home PowerPoint Templates Diagrams 5S Diagram Template for PowerPoint

5S Diagram Template for PowerPoint

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.

5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and Sustain. Each has its meaning, and the PowerPoint template depicts all of them in a sequence. Japanese started this concept of 5 stages, leading to the technique of Just in Time Manufacturing, one of the most used in the manufacturing industry. Different stages of the process are shown on the curved arrows .

This professional presentation template shows showing the flow of a process. The presentation template starts with an overview of the process, followed by a description of each stage. The first part elaborates on the Sort step dealing with selecting the necessary resources for the process and removing unnecessary ones. Required items can be listed in bullets for further analysis and monitoring. The next step is arranging all the resources appropriately and fully using them, the Straighten step. Shine includes the monitoring of the process and the environment around it. Systemize reflects quality inspection and modifications of the product to maintain a standard. The final stage is Sustain, which deals with storing and maintaining the products in a flow.

One thing to notice about this circular org chart template is the thin portion around the 5S diagram. It can add some text like the company’s motto or some motivational quote. The layout of this PPT template animates with each stage by focusing only on one stage at a time as the presentation goes on and dims the other stages. It completes a rotation by covering all the stages and highlighting the main points adjacent to the 5S diagram. It can also be used as a 30-60-90-day plan template , with each curved arrow showing a regular interval of some days to make a project timeline .

You must be logged in to download this file.

Favorite Add to Collection

Details (6 slides)

Supported Versions:

Subscribe today and get immediate access to download our PowerPoint templates.

Related PowerPoint Templates

5S Methodology PowerPoint Template

Kaizen PICK Chart Template for PowerPoint

5-Step Horizontal Infographic Diagram for PowerPoint

Lean Workplace

- History of Lean

Introduction to the 5S Method

You’ve found it. Simply put, 5S is a systematic approach to workplace organization .

But it’s also much more than that. 5S is about efficiency, competitiveness, and survival. It is a deceptively simple system that creates an organized and productive workplace.

It’s not just about cleaning up and eliminating toolboxes. 5S creates a workplace environment that can adapt and succeed.

Chaos and unproductivity are your enemies; organization and efficiency are your allies.

If implemented correctly and followed diligently, 5S will lead to:

- Lower costs

- Better quality

- Improved safety

- Increased productivity

- Higher employee satisfaction

From the offices of upper management to the workstations in the factory, the power of this system will quickly reveal itself in your bottom line.

The Five Pillars of 5S

Originally developed by Hiroyuki Hirano for manufacturing companies in Japan, the principles of 5S translate well to the laboratory, the repair facility, and even the corporate office. Almost any work environment will bene t from the structure and efficiency this model provides.

5S is sometimes called the five pillars because just like the physical pillars that hold up a structure, 5S has five elements that support the effectiveness of the system.

And just like the pillars of a building, if one was to weaken or fail, the entire structure would fall.

The five steps/pillars of 5S are:

- Set in Order

- Standardize

5S is a system, a philosophy, and a culture.

The true power of 5S reveals itself when your whole organization embraces its ideals and your employees see that your business is transforming itself. It empowers employees to take pride in the space and motivates them to maintain it.

The 5S model for workplace efficiency and organization is both powerful and simple. It has the potential to transform your company into a safe and productive warehouse, manufacturing facility, or office.

One of 5S’s most powerful attributes is that it’s a visual model . Using tools like customizable tool foam, signs, labels, and tags will greatly improve your 5S efforts. Vision is our dominant sense, and because 5S uses colors, lines, and labels to organize, following the steps becomes second nature very easily.

Remove the clutter with Sort, organize with Set to Order, clean with Shine, set your routine with Standardize, and motivate with Sustain.

Additional Resources

- 6S: Safety – creativesafetysupply.com

- Why is 5S considered a visual system? – 5sforum.com

- Achieving Organizational Excellence Through 5S Implementation – 5sexamples.com

- How 5S Can Create Sustainable Improvements Across a Business – 5svideos.com

- 5S is the Foundation of any Lean Program – infographicsdirectory.org

- Learn What 5S is and How it Applies to Any Industry – lean-video.com

- An Introduction to Kaizen – kaizensystem.net

- An Introduction to Floor Markings – facilityfloortape.com

- How to Apply Kaizen in Different Industries – kaizenforums.com

Related posts:

- Lean Manufacturing & Lead Time

- What is the Toyota Production System?

- The Tools of Lean

- What is Lean Manufacturing?

- What is Gemba?

- Understanding the Terms of Lean

- Introducing the House of Lean

- What is Six Sigma?

- Improving Lean in the Workplace

5S Methodology: The Ultimate Guide

What is 5S Methodology

5S Methodology is a workplace organization method that uses a list of five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), and Shitsuke (Sustain) to organize a workspace for efficiency and effectiveness.

By identifying and storing the items used, maintaining the area and items, and sustaining the new organizational system, 5S helps organizations improve efficiency, avoid wastage, reduce delays, and become competitive.

Simply put, 5S is a systematic approach to workplace organization that leads to reduced costs, increased sales, and a more agile workplace.

Origin of 5S

In Post-World War II Japan, Toyota’s President, Kiichiro Toyoda and chief engineer Taiichi Ohno visited the U.S. to study the assembly line at Ford and were dismayed by the wastage in manufacturing process.

In contrast, when Kiichiro visited a Piggly Wiggly Supermarket, he was impressed with their system of reordering and restocking as and when goods were purchased.

This inspired them to develop the Just In Time (JIT) manufacturing system at Toyota, the foundations of which lie in 5S. Largely due to Toyota’s success, companies from a variety of industries have since integrated 5S practices into their own processes.

HP, Boeing, Harley-Davidson, Nike, Caterpillar, and Ford are just a few examples that found success with 5S.

Benefits of 5S

Benefit 1: zero wastage.

5S efficiently minimizes waste by eliminating unnecessary storage spaces and reducing “stand-by waste”, such as inventory waiting for equipment. This approach also tackles waste arising from the improper allocation of space and equipment. It even addresses wasteful motion resulting from activities like searching and sidestepping.

The core of the methodology lies in eliminating actions that do not add value, such as the redundant tasks of picking up, putting down, counting, and carrying. With this approach, 5S optimizes processes and enhances overall efficiency.

Benefit 2: Improved Safety

Organizations practising 5S keep their equipment in spotless condition, making mechanical failures and hazards immediately visible. Places are well-defined, and things are stored in designated places. In an industrial setup, this plays a crucial role in eliminating safety incidents and being better prepared in case of an emergency.

Benefit 3: Zero Breakdowns

5S promotes better maintenance by eliminating trash, dirt, and dust which cause equipment breakdowns and shorten life.

By keeping the workspace sparkling clean and free from filings, oil leakage, etc. it becomes easier to monitor equipment condition. Periodic checks built into the 5S keeps breakdowns to a minimum.

Benefit 4: Zero Defects

Defects are harder to discover when the workplace is unorganized. 5S designates a proper place for everything. A clean and well-organized workplace makes workers more conscious of the way they produce things.

Benefit 5: Zero Changeovers

Most factory workers have simply grown accustomed to “searching” as part of their jobs. The more searching they do, the lower their productivity sinks and the more obsolete their factory becomes.

Implementation of the 5S’s makes workshops simple and transparent enough for observers to understand with ease. Proper arrangement of dies, jigs, and tools eliminates this major form of waste called “searching waste.”

Benefit 6: Zero Delays:

When defects are eliminated, deliveries are on time. Good work environments help increase operational efficiency, leading to waste-free workshops.

Benefit 7: Zero Complaints

Products that come from a neat and clean workshop often have no defects, cost less to make and are delivered on time.

Benefit 8: Positive financial impact

Customers are happy to buy from manufacturers that have rid themselves of waste, injuries, breakdowns, and defects. Companies following 5S at workplaces earn more respect and trust in their community and turn competitive.

Meaning of the five ‘S’ in 5S

Seiri (sort).

The word Seiri (to Sort) means proper arrangement and goes beyond lining things up in rows or piling them into neat stacks. It is required to clearly distinguish between what is needed and kept and what is unneeded and thrown out.

Some questions to ask during this phase include:

- What is the purpose of this item?

- When was this item last used?

- How frequently is it used?

- Who uses it?

- Does it need to be here?

Organizations hold onto excess parts, believing they might be of future use. Inappropriate machines are used simply because they are readily available. Eventually, this starts hindering everyday production activities, leading to a mass buildup of waste that spreads far and wide through the factory.

In Seiri, the following types of waste are identified and eliminated:

- Unwanted inventory

- Warehouse space and shelving that do not contribute to the production

- Stocked items that could become obsolete

- In-process inventory

- Equipment that is no longer needed

Visible methods of proper arrangements, such as red-tagging (discussed later), make it easier to identify and eliminate waste.

Seiton (Set in order)

When everything is properly arranged, the only things that remain are the necessary ones. Hence, the next step is to clarify where these things belong. Seiton means to set things in order and goes hand-in-hand with proper management (Seiri).

In this sense, orderliness means designating a place for every item to be kept such that it becomes easier for anyone to find and use.

Things to consider in Seiton include:

- Which people (or workstations) use which items?

- When are items used?

- Which items are used most frequently?

- Should items be grouped by type?

- Where would it be most logical to place items? Would some placements be more ergonomic for workers than others? Would some placements cut down on unnecessary motion?

- Are more storage containers necessary to keep things organized?

During this phase, everyone should determine what arrangements are most logical. This requires thinking through tasks, the frequency of those tasks, the paths people take through the space, etc.

Businesses may want to stop and think about the relationship between the organization and larger Lean efforts. What arrangement will cause the least amount of waste?

One of the key principles of 5S is that anyone must be able to easily understand the order of things in the workspace. This is different from the usual mindset of having to “learn the ropes” or “become a veteran” before understanding where things go.

Seisō (Shine or Clean)

Seisō promotes the practice that cleanliness does not stop at home and that keeping the workplace clean is closely related to the ability to turn out quality products.

Seisō integrates cleanliness into everyday maintenance tasks. By demolishing the distinction between an operator’s work and a maintenance technician’s work, Seisō requires everyone to get involved in maintaining a clean, orderly workspace.

Activities carried out in Seisō include cleaning up the work area, which means sweeping, mopping, dusting, wiping down surfaces, putting tools and materials away, etc.

Seiketsu (Standardize)

Unlike the first three stages, which are seen as activities, Seiketsu refers to a state. Seiketsu means that the first three S’s (Seiri, Seiton, & Seisō) are being maintained.

When a new company implements 5S, it is easy to clean and get organized but gradually, things slide back to the way they were. Seiketsu systematizes the improvements undertaken in the previous three steps and turns these one-time efforts into habits.

By assigning regular tasks, creating schedules, developing standard operating procedures for 5S activities, and posting instructions, Seiketsu ensures that orderliness doesn’t fall by the wayside.

Initially, people will need reminders, and a small amount of time will have to be set aside for 5S tasks, but over time, these tasks become routine and 5S becomes a habit.

Shitsuke (Sustain or Discipline)

Shitsuke is seen as the most important of the 5S’s and is a pivotal factor for the production system as a whole. It is about making 5S a long-term program.

Shitsuke is top-driven, i.e., the seeds of workspace discipline need to be planted by the organization’s bosses and managers by showing their commitment to 5S.

Some of the strategies to drive this step include:

- Audits: managers can take responsibility for maintaining the routines and send a message about their commitment to 5S. Through a coaching attitude, the audit team discusses problems to find long-term solutions.

- Rewards & recognition: Celebrating success is an important part of 5S implementation. Departments and individuals are recognized for their efforts and their successes are displayed for everyone to see.

The goal of Shitsuke is to make 5S a part of an organization’s culture so that businesses achieve continuous positive results.

Implementing 5S

One of the easiest ways to implement 5S is to make the whole array of waste, abnormal operations, and other problems as explicit and visible as possible. This is also referred to as “Visual Management”.

Vision is our dominant sense, and because 5S uses colors, lines, and labels to organize, following the steps becomes second nature very easily. While 5S stands as the foundation for improvement, “visible 5S” is what every 5S initiative must become in order to be preserved.

Numerous process tools can help make 5S successful. Some of them as shown in the figure:

1. Red Tag Strategy

The red tag strategy is a means of implementing proper arrangement by labeling all unneeded items with conspicuous red tags. It involves six steps as follows:

Step 1: Launching the red tag project

Organizations need to carry out factory-wide red tag campaigns at least once or twice a year. A top manager takes responsibility for such a campaign while project members from every division come together in the identification and disposal of unnecessary stock and equipment.

Step2: Identifying Red Tag target area

The main targets for red tags are inventory, equipment, and space. Inventory can be divided into warehouse inventory and in-process inventory.

It is also important to target inventory that does not have a specified location, such as the ones that get piled up alongside aisles or on shelves in the factory. Unnecessary paperwork, along with superfluous desks, lockers etc., also count as target areas in this step.

Step 3: Setting Red Tag Criteria

Organizations are reluctant to throw familiar things away. Establishing well-defined criteria for deciding what is needed and what is not helps address this challenge.

One of the approaches to setting criteria is to look at the 30-day production schedule. What is needed for that schedule is to be retained while the rest could be classified as red-tag items.

Step 4: Make the Red Tags

While organizations can customize the red tags based on their specific needs, at a minimum, the following information is necessary:

- Category (warehouse item, machine, raw materials, in-process inventory etc).

- Quantity indicating the number of items included under the red tag.

- The reason why a red tag is attached (not needed, defective, etc.)

- Responsibility – Department/individual in charge of managing the red-tagged item.

- Date of tagging.

Step 5: Attach the Red Tags

The red-tagging team must thoroughly understand the criteria for selecting the unneeded items. As a good practice, people attaching red tags must not belong to the area being tagged. This ensures that the team is unhindered by sentimental resistance or regret.

The key to a good red-tagging strategy is to cover the whole workspace in as short a time as possible. It is important to regard red-tagging as a swift and powerful event.

Step 6: Evaluate the Red Tag Targets

Red-tagged inventory items can be treated as per the below workflow:

Red-tagging equipment is just as important as warehouse inventory. All such equipment must be moved away from the production area. In case of large equipment that cannot be moved, a “freeze” red tag must be used to indicate that the equipment should not be used for production activities.

2. Signboard Strategy

A signboard strategy is a tool to make the organizing process of 5S more visible. It should always be preceded by the red tag strategy to avoid efforts in posting signboards over unneeded items.

The below figure gives an overview of visible orderliness using the signboard strategy:

The goal of the signboard strategy is to consolidate what is left after a red-tagging exercise and arrange the equipment layout/production flow pattern in the most efficient and orderly way. It consists of six steps:

Step 1: Determine the locations

To consolidate the equipment layout and the production flow, it is important to determine how things should be placed to best suit the layout. Items that are frequently used must be placed closest to the operator. Ergonomic factors must also be considered in this step.

Step 2. Prepare the Locations

Cabinets, shelving, boxes, pallets, and containers must be used to ensure easy accessibility of storage items (Some of these may be found in red-tagged items and can be repurposed). For better efficiency, First-In First-Out Order [2] , or labor-saving roller conveyors may be used.

Step 3: Indicate Locations

Signboards must indicate the place and the address of items. It is essential to indicate where in the factory the item belongs and what specific address in a particular area.

Step 4: Indicate Item Names

While the placement indicators show where the items belong, item indicators identify each item.

When item indicators include data such as information used to maintain the “pull production” system [3] , operation instructions, and/or delivery instructions, these simple signboards turn into a full-fledged Kanban. [4]

Step 5: Indicate Amount

The purpose of amount indicators is to limit the number of shelves and storage space to be used for inventory items. Unless the amount of inventory items is kept under check, they tend to pile up.

When the exact quantity cannot be indicated, the minimum and maximum must be indicated.

The goal of a good indicator is to help visibly identify abnormalities, waste, and other problems immediately.

Step 6: Maintaining Orderliness

The key to maintaining a successful signboard strategy is to respond to problems as soon as they arise by identifying the causes and making appropriate improvements. Making orderliness easy to maintain, sticking to discipline, and making 5S’s a daily habit is crucial.

3. Organizing by color code

The best way to manage liquids like oil, lubricants, fuel etc. is through color-code. Color-coding the containers and applying the same color-coding to the areas where each type of liquid is stored helps keep the inventory organized.

4. Outlining

Marking outlines around the standardized places for keeping things clearly shows anyone where an object belongs. These can be in the form of tapes/paint strips that mark the locations where equipment or materials are placed or highlight hazards.

They come in a variety of colors and patterns, and can also be used on shelves, workbenches, cabinets, and other surfaces.

5. Checklists

Checklists provide a structured approach to achieving efficiency and organizing the workplace. They serve as a guide to ensure that each of the five steps in 5S is systematically followed and completed.

Checklists enhance communication, facilitate accountability, and serve as a visual reminder of the tasks at hand.

6. Tools for developing discipline in 5S

Badges serve as powerful visual reminders of an organization’s dedication to the principles of 5S. They encourage engagement and foster a sense of pride among employees, promoting a culture of organization, cleanliness, and efficiency at the workplace.

5S mini motto boards

Small signboards can be used to post 5S-related mottoes. Such mottoes can be invented by the company’s own workers to heighten awareness and participation. Mottoes & illustrations must be simple enough to be read and understood in under a minute and must be updated frequently.

5S stickers

Stickers act as visual cues to reinforce the principles of 5S. By labeling tools, equipment, and workstations, they remind employees to maintain organization and cleanliness, promoting discipline and adherence to standardized practices in the workplace.

5S contests

5S contests foster discipline by instilling a sense of competition among employees to maintain the best-organized workspace. They encourage individuals and teams to sustain a disciplined approach to organization, cleanliness, and efficiency, ultimately enhancing productivity and overall workplace discipline.

5S patrols contribute to discipline by assigning designated personnel to regularly inspect work areas. Documenting adherence to 5S standards, identifying areas needing improvement, and prompt timely corrective actions helps improve accountability and feedback mechanism.

5S Photo exhibits

5S photo exhibit shows before-and-after images of workspaces, illustrating the impact of implementing 5S principles. These visual representations motivate employees to maintain order, cleanliness, and standardization, fostering a sense of pride and discipline in upholding improved organizational practices.

Maps showcasing factory layouts enable visitors and passersby to easily refer to and identify areas that require better implementation of the 5S’s. Memo pads must be provided alongside maps for taking notes on potential improvements.

Maps help organizations capitalize on collective insights and contributions, fostering a more organized and efficient environment.

Keys to successful 5S implementation

To ensure the success of any 5S strategy, it is important to organize a “5S Promotion Team”. Such a team is tasked with the responsibility of maintenance and further improvements in 5S.

The following eight points, known as “Eight Keys to 5S Success” are crucial in establishing and maintaining 5S workshops.

Key #1: Getting everyone involved

5S’s cannot be the responsibility of a concerned few. Everyone must get into the act.

All levels of factory management should take part in the decision-making. 5S activities are successful when carried out as a part of the factory’s small-group activities. [7]

Key #2: Get company authorization

Management approval is important in performing 5S activities. A companywide collaborative approach must be followed while avoiding working in isolation.

Key #3: Role of the top management

The 5S’s will not be taken seriously until the CEO/President takes personal responsibility and interest in its implementation. The role of leadership in promoting 5S is crucial.

Key #4: Make everyone understand

Clarity is crucial in 5S. Teams must explain the purpose, method and action plan and address questions from all participants. Using practical examples of successful 5S implementation, including tours of well-maintained workshops, helps bring clarity.

Key #5: Do it all the way

Commitment to 5S is important. Diligent red tag campaigns, clear signboards, well-defined standard operating procedures etc. go a long way in making 5S a success.

Key #6: Top management should drive the initiative

The CEO/president must personally inspect factories and point out their observations. This motivates the group to commit to making the workplace better.

Key #7: Don’t stop halfway in establishing the 5S’s

Once the 5S promotional organization and methods have been established, it is important to follow them all throughout. Developing habits that bring discipline is crucial to keeping the foundation strong.

Key #8: 5S is a continuous improvement process

The act of organizing the workplace, looking for improvements, and optimizing is a continuous process. A successful 5S strategy is one with a shifting goal where there is always room to do better.

Industries using 5s

5S methodology is versatile enough to be used in a variety of industries. Below are some of the industries that have benefited from the 5S methodology.

1. “JIT Implementation Manual — The Complete Guide to Just-In-Time Manufacturing: Volume 2 — Waste and the 5S’s 2nd Edition”. Hiroyuki Hirano, https://www.amazon.com/Implementation-Manual-Complete-Guide-Manufacturing/dp/1420090240 . Accessed 16 Jul 2023

2. “FIFO – First In First Out Warehousing”. Ogiwa, https://www.logiwa.com/blog/first-in-first-out-warehousing . Accessed 18 Sep 2023

3. “Pull Production”. Lean.org, https://www.lean.org/lexicon-terms/pull-production/ . Accessed 19 Jul 2023

4. “What Is the Kanban System?”. Investopedia, https://www.investopedia.com/terms/k/kanban.asp . Accessed 18 Jul 2023

5. “World-class Lubrication Program Transformation”. Machinerylubrication.com, https://www.machinerylubrication.com/Read/881/world-class-lubrication . Accessed 18 Jul 2023

6. “5s Guide”. Creative Safety Supply, https://www.creativesafetysupply.com/content/landing/5S-poster/index.html . Accessed 18 Jul 2023

7. “Small Group Activity – SGA”. Makigami, https://www.makigami.info/continuous-improvement-tools/small-group-activity-sga/ . Accessed 19 Jul 2023

- Six Sigma: The Definitive Guide

Leave a Comment Cancel reply

Save my name and email in this browser for the next time I comment.

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Tools

What is 5S? And What Are the Benefits?

- 8 mins to read

- November 18, 2022

- By Reagan Pannell

An Introduction

This article is focused on one aspect of Lean Thinking, the concept of Workplace Organisation known as 5S. It is one of the critical Fundamental of Lean concepts. If you are looking for a more general introduction to Lean, check out our Free Fundamentals of Lean Course . So lets get started.

What is 5S, and what are its benefits

The 5S methodology is a system for improving productivity and efficiency in the workplace. If you follow the best 5s practices, including 5S implementation in office environments or within a manufacturing process, you can quickly improve productivity, employee and engagement.

In fact, we are all aware of these concepts from our grandfathers that had tools lined up perfectly in the shed using Shadow Boards, through to proper cleaning procedures for critical equipment across various sectors. The continuous improvement plan 5s, can unlock incremental improvements and build the discipline needed with the culture to always strive to improv.

The five “S”s stand for sort, set in order, shine, and standardise and sustain. By understand the 5S meaning and conducting a 5S analysis teams adhering to these guidelines can improve work flow and reduce wasted time and energy. 5S can benefit businesses in several ways, including reducing costs, improving quality and speeding up production times. Implementing 5S can be challenging, but the benefits are well worth it.

5S is a Japanese methodology for organising and improving work environments.

What are the 5s?

The name comes from the five steps Sort, Set, Shine, Standardise, and Sustain . The goal of 5S is to eliminate waste and improve efficiency by creating a well-organised and clean workplace.

The benefits of 5S are numerous. A well-implemented 5S program can lead to reduced lead times, increased productivity, improved safety, and decreased costs. It can also reduce waste within a process. In addition, 5S can help create a culture of continuous improvement by engaging employees in identifying and addressing problems and creating a “visual factory”. Ultimately, the 5s experience is an an effective tool for creating a leaner and more efficient organization. It is perhaps one of the most important of all the tools. It is critical to drive a problem solving culture. Always to remember the five s’s and then follow them in consecutive order to help improve visual management and the visual workplace.ly c

The origins of 5S – 5S & Lean Manufacturing

5S started in the Toyota production system – the manufacturing method of Toyota’s founders in the early and middle 20th. In the West, the Lean manufacturing method was often called Lean or Lean Manufacture. It is aimed at increasing product value to consumers. This can sometimes be achieved by identifying or reducing waste in the production process. Lean manufacturing combines various equipment like 5S, Kaizen Kanban, jidoka, heijunka or poka-yoke. 5S is considered an integral component of Toyota’s product manufacturing system since without an organized, well-organized environment, achieving consistently good results is difficult.

- Visit our Consultancy page

GB MASTERCLASS COURSE

Get access to our free gb mastercourse classes, free course previews, visit our free course, ready to level up your career, lean six sigma courses, lean six sigma training, ready to level up your career, get free access to our certified lean six sigma courses, tell me about the 5s methodology..

5S was traditionally defined by the philosophy of “all things in their place.” You might recall Marie Kondo’s home organisation system, “Konmari“. KonMari methods transform a messy house into a clean and simplified living room. The five-part principle is identical to KonMari.

A sixth “S” for safety

In the field of lean manufacturing, fiveS has been widely used. The tools for lean manufacturing have become the best in the business world and are widely used. 5S increases productivity, reduces costs and enhances quality. Often the lean program focuses on these objectives, and the human factor does not appear. The security of employees is essential. Many facilities now add a second step to the 5-year cycle and call it six steps in terms of safety. Like the five first-level steps, safety does not take a series of actions sequentially. This needs consideration for every other step. You may decide in a sorted phase that the given software will be obsolete due to the safety of using new versions. So often within the manufacturing industry, in particular, we find the 6S being used to place importance on safety within the work environment.

5S Guide: Improve efficiency with effective organisation

During a lousy job environment, things slow down. 5S – based on systematic methods to organise workplaces, helps you keep the workspace clean so processes can run efficiently. This 5S Guide describes how to start 5S programs how to create them and the power of 5S to drive business performance.

It contains five steps: sort, set, shine, standard and sustain . 5. This generally involves examining the item on the workspace, removing unnecessary things, organising the items and cleaning up and maintaining things so that the things can grow into habits.

5s manufacturing best companies always build 5s roles and responsibilities when launching a program. So consider who is going to do what when and who will maintain, monitor and follow up throughout the program.

Workplace Organization Guide: Learn simple strategies for long-term success

When the workplace is cluttery, the processes are less effective and more efficient. This quick guide to the organisational workplace covers simple ways and methods for a workplace that is organised anywhere.

5S is incorporated into the work process instead of if it is separate from it. It can also alter how work is performed. In a 5s system, workers perform 5S tasks within everyday tasks.

How does 5S improve visual management within the workplace?

The 5S methodology provides a systematic approach to workplace organization that not only promotes efficient processes but also helps ensure the safety of workers. One key area where 5S improves visual management within the workplace is in its emphasis on labelling and categorizing all items within a workspace.

This includes labelling everything from equipment and tools to storage containers, bins, and shelves. By adequately labelling each item, it’s easy for employees to quickly locate what they need while also reducing confusion when multiple people are working in the same space. Additionally, this visual system can help reduce clutter and optimize workflow by ensuring that all materials are located correctly. Furthermore, regular inspections can be conducted to identify misplaced items or any potential hazards before they become an issue.

5S Improvements are an essential part of TPM (Total Production Maintenance) – learn more!

Making improvements so the Visual Workplace

Not only does 5S improve visual management within the workplace, but it also helps to maintain the Visual Workplace. This includes everything from implementing effective cleaning routines to periodic audits and inspections. Regularly scheduled cleaning can help reduce dirt, dust, and other debris that can potentially interfere with a workspace’s efficiency. Additionally, regular inspections of all equipment and tools can help identify potential issues before they become serious problems. Finally, by keeping a record of these inspections, it will allow you to track improvements over time while also ensuring that all safety measures are being enforced correctly.

By using 5S as part of your daily routine, you can not only reduce clutter in the workplace but also increase efficiency and safety for your workers. Its a core part in benefiting from continious improvement . Investing in the right tools and strategies ensures your workplace remains organized while also achieving your production goals. Finally, 5S allows you to easily make changes over time as needed and keep up with the ever-changing landscape of modern manufacturing.

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

Is 5s important in manufacturing and 5s principle in tqm.

Although 5S was first developed within automotive, it is considered a key part of all Lean manufacturing plans based on industry. Incorporating 5S in your organization will go far beyond improving organization, consistent cleaning routines, and efficient activities flow. The 5s method encourages operators to improve the overall workplace environment and reduce mud or waste. The 5 s standards were established as a fundamental component of Total Products Maintenance (TPM) and incorporated into Toyota Production Systems (TSPS). 5S offers an open platform for Kaizen activities.

The steps of 5 steps

The 5 S were initially made in Japan, and its Japanese name is the original “S”. Therefore, the ensuing translation for each step may differ depending on the language used. The basic concepts are easily understandable, however. These steps work together, and therefore the sequence is essential. Clearance of unnecessary items will provide the space necessary for organizing essential things in step 2. Once the workspace is reorganized, it is easy to eliminate all dirt or grime. These new duties must also be included in implementing the updated Step 3 standard. When all else is done and the work environment looks excellent, a consistent step 4 can be used to maintain that standard. Lastly, Step 5 develops a culture of Continuous Improvement to sustain optimization.

How to start a 5S program in your workplace

A 5S program is a system for organisation and standardisation that can be applied to any workspace. The 5S acronym stands for Sort, Set in Order, Shine, Standardise, and Sustain. When implementing a 5S program, the first step is to Sort through all items in the workspace and remove anything that is not essential. Next, everything must be Set in Order so that it is easy to find and use.

The workspace should then be clean, free of clutter and debris. Standardising procedures will help to ensure that the workspace remains organised, and finally, the Sustainability phase involves maintaining the program on an ongoing basis. Following these steps can create a more efficient and productive workplace.

Tips for sustaining a 5S program over time

Sustaining a 5S program can be challenging, but a few key things can help. First, selecting the right employees to serve on the 5S team is important. Look for individuals who are committed to continuous improvement and have strong organisational skills.

Next, make sure that the 5S team has adequate resources, including time, budget, and training. Finally, establish regular communication channels between the 5S team and the rest of the organisation. This will help ensure that everyone knows the program’s goals and progress. By following these tips, you can create a 5S program that will continue to improve your workplace for years to come.

Case studies of successful 5S implementations

5S is a system of organisation and standardisation that can be used in any workplace. The 5S philosophy is based on the following principles: Sort, Set in Order, Shine, Standardise, Sustain. 5S can lead to increased productivity, improved safety, and reduced waste when implemented correctly. There are many examples of successful 5S implementations across a variety of industries

One well-known example comes from the Toyota Motor Corporation. In the early 1990s, Toyota was struggling with quality control issues. They decided to implement a 5S program in their factories. The results were impressive: over the next few years, Toyota’s quality improved dramatically, and it became one of the world’s leading automakers

The U.S. Army undertook another successful implementation of 5S at Fort Hood in Texas. In 2006, the Army decided to implement 5S to improve safety and increase efficiency. The results were significant: over the next few years, accidents decreased by 50%, and productivity increased by 15%

These are just two examples of how 5S can lead to improvements in any workplace. When implemented correctly, 5S can help to make any workplace more organised, efficient, and safe.

Resources for learning more about 5S

When it comes to 5S, there are a variety of resources available to help you learn more about this Lean manufacturing methodology. Books, articles, and online courses can all provide valuable insights into how to implement 5S in your workplace.

One great resource is the book “5S for Operators: The Secret to Japanese Success” by Hiroyuki Hirano. This book provides a step-by-step guide to implementing 5S in any manufacturing or production environment. It covers everything from why 5S is important to how to conduct a successful 5S audit.

If you’re looking for a more general overview of 5S, the article “5S Made Easy” from Industry Week is a great place to start. This article provides an overview of the basics of 5S and how it can benefit any organisation.

Finally, if you want to dive deeper into the specifics of 5S implementation, online courses like “5S for Manufacturing” from Simpler Consulting can provide valuable insights. These courses offer an in-depth look at everything from identifying wasted time and motion to implementing visual controls.

By taking an online Lean Thinking Online Course , you can learn at your own pace and ensure that you understand all the nuances of 5S before trying to implement it in your own workplace.

Benefits of a 5S program – Continuous Improvement

Since 5S is a program to improve a workplace and varies workplaces may not share a common theme, the results are hard to forecast. However, there are often many advantages that are not simply pleasant feelings. Despite initial and subsequent problems with 5S, many facilities now show measurable improvement. Several schools in the US have implemented lean programs since 2009.

They slowed processing time and travel time by 83% reducing labor and time costs from $700 to $1000 every year. By driving up workplace organisation, you naturally drive down cycle times , which in turn reduces lead time, effort, and work in progress and ultimately drive up customer satisfaction.

Training and certification

How can we train our teams in 5S for success? How? How can you train a new staff member? Although the exact curriculum of 5S training programs will vary, it’s critical for your team to learn the five principles for effective implementation, regardless of the amount of organisational transformation they make on their own journey.

5S is a business improvement methodology that can be applied in any workplace. It helps to create a more organised and efficient environment by streamlining processes and eliminating waste. When implemented correctly, 5S can lead to improved productivity, quality, and safety in the workplace. There are many resources available to help you get started with 5S in your organisation, including our own online courses . With the right tools and training, you can start seeing improvements in your business today

- Corporate Training

- Courses for Individuals

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

Fundamentals of lean.

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, what is the 1 proportion test in lean six sigma, what is the difference between lean & six sigma, what qualities do employers look for in potential employees, principle 6: how standardisation can grow your creativity | principles of lean, 16th june 2023 | 5-bullet friday newsletter from leanscape, what are the benefits of cpd for lean certifications, the box plot: a comprehensive overview, why are control plans essential in project management, online business courses free: the benefits for professionals, what are p-values and how to use them in six sigma, murphy’s law, poka yoke & lean in hospitals, 5-thought friday | 24th march 2023.

- | 5s , lean , toolkit , tools

Related Articles