Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

Metals and alloys articles within Scientific Reports

Article 26 March 2024 | Open Access

Electrochemical properties of MnSe inclusions and improving the pitting corrosion resistance of stainless steel via Se microalloying

- Masashi Nishimoto

- , Tomoki Katsuyama

- & Izumi Muto

Article 16 March 2024 | Open Access

Influence of nano-BN inclusion and mechanism involved on aluminium-copper alloy

- & Rong Li

Article 04 March 2024 | Open Access

Revealing process and material parameter effects on densification via phase-field studies

- , Henrik Hierl

- & Wolfgang Rheinheimer

Article 22 February 2024 | Open Access

Combined effect of interstitial-substitutional elements on dislocation dynamics in nitrogen-added austenitic stainless steels

- Yasuhito Kawahara

- , Shunya Kobatake

- & Jun-ichi Hamada

Article 12 February 2024 | Open Access

Transitioning solidification mode via electroplated Ni coatings in martensitic stainless steel resistance spot welds: new insights into fabricating tough microstructure

- Hamidreza Aghajani

- , Milad Bahrami Balajaddeh

- & Majid Pouranvari

Article 05 February 2024 | Open Access

Intermetallic and dispersoid structures in AA3104 aluminium alloy during two-step homogenisation

- S. L. George

- & L. Magidi-Chicuba

Unsupervised machine learning combined with 4D scanning transmission electron microscopy for bimodal nanostructural analysis

- Koji Kimoto

- , Jun Kikkawa

- & Fumihiko Uesugi

Article 16 January 2024 | Open Access

Properties of Al x Ga 1−x As grown from a mixed Ga–Bi melt

- Olga Khvostikova

- , Alexey Vlasov

- & Vladimir Khvostikov

Assessment of refining efficiency during the refining cycle in a foundry degassing unit in industrial conditions

- Ladislav Socha

- , Tomáš Prášil

- & Petr Nuska

Article 11 January 2024 | Open Access

Crack reduction in laser powder bed fusion of MnAl(C) using graphene oxide coated powders

- Simon Tidén

- , Himesha Abenayake

- & Martin Sahlberg

Article 10 January 2024 | Open Access

Multifunctional metallic nanocomposite for overcoming the strength–ductility trade-off

- Asheesh R. Lanba

- , Reginald F. Hamilton

- & Richard F. Gordon

Article 04 January 2024 | Open Access

Development of deoxidation process for off-grade titanium sponge using magnesium metal with wire mesh strainer type of crucible

- Sung-Hun Park

- , Hyeong-Jun Jeoung

- & Jungshin Kang

Article 03 January 2024 | Open Access

Quasi-instantaneous materials processing technology via high-intensity electrical nano pulsing

- Eugene A. Olevsky

- , Runjian Jiang

- & Elisa Torresani

Article 27 December 2023 | Open Access

Impact of crystalline orientation on Cu–Cu solid-state bonding behavior by molecular dynamics simulations

- Hiroaki Tatsumi

- , C. R. Kao

- & Hiroshi Nishikawa

Article 21 December 2023 | Open Access

A study on the fabrication of metal microneedle array electrodes for ECG detection based on low melting point Bi–In–Sn alloys

- Hyunjong Gwak

- , Sungbo Cho

- & Soonmin Seo

Article 11 December 2023 | Open Access

Biaxial tensile behavior of stainless steel 316L manufactured by selective laser melting

- , Xiaoyong Shu

- & I. V. Alexandrov

Article 07 December 2023 | Open Access

Change of dominant material properties in laser perforation process with high-energy lasers up to 120 kilowatt

- Stefan Reich

- , Marcel Goesmann

- & Jens Osterholz

Article 03 December 2023 | Open Access

Structural characterization of newly-developed Al 79 Ni 5 Fe 5 Y 11 and Al 79 Ni 11 Fe 5 Y 5 alloys with amorphous matrixes

- Katarzyna Młynarek-Żak

- , Indu Dhiman

- & Rafał Babilas

Article 21 November 2023 | Open Access

Crystal plasticity simulations with representative volume element of as-build laser powder bed fusion materials

- Dmitry S. Bulgarevich

- , Sukeharu Nomoto

- & Masahiko Demura

Article 06 November 2023 | Open Access

Improved maximum likelihood method for P-S-N curve fitting method with small number specimens and application in T-welded joint

- & Hailang Liu

Article 27 October 2023 | Open Access

Understanding the hot isostatic pressing effectiveness of laser powder bed fusion Ti-6Al-4V by in-situ X-ray imaging and diffraction experiments

- Tatiana Mishurova

- , Sergei Evsevleev

- & Giovanni Bruno

Article 18 October 2023 | Open Access

Characterisation of AZ31 metal matrix composites reinforced with carbon nanotubes

- Sandeep Ganesh Mukunda

- , Satish Babu Boppana

- & T. Aravinda

Article 09 October 2023 | Open Access

Research on the integral forming process of thin walled and thick mouth seamless gas cylinders

- , Haofei Yu

- & Qiaofeng Bai

Article 06 October 2023 | Open Access

Design of Laves phase-reinforced compositionally complex alloy

- Gerald Ressel

- , Florian Biermair

- & Vsevolod I. Razumovskiy

Article 04 October 2023 | Open Access

Effect of microstructure refinement of pure copper on improving the performance of electrodes in electro discharge machining (EDM)

- Jacek Skiba

- , Mariusz Kulczyk

- & Kamil Nowak

Probing corrosion using a simple and versatile in situ multimodal corrosion measurement system

- Sridhar Niverty

- , Rajib Kalsar

- & Vineet V. Joshi

Article 23 September 2023 | Open Access

Key topographic parameters driving surface adhesion of Porphyromonas gingivalis

- , Mathieu Maalouf

- & Virginie Dumas

Article 16 September 2023 | Open Access

The effect of material defect orientation on rolling contact fatigue of a ball bearing

- Akbar Ghazanfari Holagh

- & Javad Alizadeh Kaklar

Interactions between C-steel and blended cement in concrete under radwaste repository conditions at 80 °C

- Margit Fabian

- , Otto Czompoly

- & Laurent De Windt

Article 06 September 2023 | Open Access

The role of internal defects on anisotropic tensile failure of L-PBF AlSi10Mg alloys

- Zhengkai Wu

- , Shengchuan Wu

- & Philip J. Withers

Article 02 September 2023 | Open Access

Experimental investigation and quantitative prediction in interference-fit size of CFRP riveted joints under a transversal ultrasonic vibration-assisted riveting

- Xingxing Wang

- , Yunyang Shi

- & Yegao Chen

Article 21 August 2023 | Open Access

Off-stoichiometry and molybdenum substitution effects on elastic moduli of B1-type titanium carbide

- Shuntaro Ida

- , Kotaro Hoshizaki

- & Kyosuke Yoshimi

Article 17 August 2023 | Open Access

Strengthening the mechanical characteristics and cathodic delamination resistance of fiber-reinforced polymer through chemical surface modification of glass fibers

- M. Shariatmadar

- , S. Feizollahi

- & M. Mahdavian

Article 16 August 2023 | Open Access

Experimental study on high temperature tensile behaviour of aluminium alloy AA5083 with oscillating load

- Mohammad Shirinzadeh Dastgiri

- , Zackary Fuerth

- & Daniel Green

Article 08 August 2023 | Open Access

Corrosion behavior and microstructure of Al–10Zn alloy with nano CuO addition

- Eman AbdElRhiem

- , Saad G. Mohamed

- & Shereen M. Abdelaziz

Article 04 August 2023 | Open Access

Artificial intelligence inspired design of non-isothermal aging for γ–γ′ two-phase, Ni–Al alloys

- Vickey Nandal

Article 22 July 2023 | Open Access

Generation of synthetic microstructures containing casting defects: a machine learning approach

- Arjun Kalkur Matpadi Raghavendra

- , Laurent Lacourt

- & Henry Proudhon

Article 15 July 2023 | Open Access

Efficient machine learning of solute segregation energy based on physics-informed features

- & Zhiliang Pan

Article 01 July 2023 | Open Access

Feasibility of orbital friction stir welding on clad pipes of API X65 steel and Inconel 625

- C. V. Amavisca

- , L. Bergmann

- & B. Klusemann

Article 29 June 2023 | Open Access

Measurements and predictions of diffusible hydrogen escape and absorption in catholically charged 316LN austenitic stainless steel

- Melissa Weihrauch

- , Maulik Patel

- & Eann A. Patterson

Article 28 June 2023 | Open Access

First-principles demonstration of band filling-induced significant improvement in thermodynamic stability and mechanical properties of Sc \(_{1-x}\) Ta \(_{x}\) B \(_{2}\) solid solutions

- Kunpot Mopoung

- , Annop Ektarawong

- & Björn Alling

Article 20 June 2023 | Open Access

Controlling grain structure in metallic additive manufacturing using a versatile, inexpensive process control system

- Lova Chechik

- , Alexander D. Goodall

- & Iain Todd

Article 19 June 2023 | Open Access

Nanosilica treatment enables moisture-resistant hydrophobic arc welding covered electrodes

- Mohammadreza Pasandeh

Article 12 June 2023 | Open Access

Analysis of the carbide precipitation and microstructural evolution in HCCI as a function of the heating rate and destabilization temperature

- M. Agustina Guitar

- , U. Pranav Nayak

- & Frank Mücklich

Article 09 June 2023 | Open Access

Heat source modeling, penetration analysis and parametric optimization of super spray MAG welding

- & Yimin Xia

Article 05 June 2023 | Open Access

Crack mechanism and experimental verification on straightening of AZ31B magnesium alloy plate

- Rong-Jun Wang

- & Lian-Yun Jiang

Article 31 May 2023 | Open Access

Femtosecond laser-induced nano- and microstructuring of Cu electrodes for CO 2 electroreduction in acetonitrile medium

- Iaroslav Gnilitskyi

- , Stefano Bellucci

- & Orest Kuntyi

Article 22 May 2023 | Open Access

Impact of d -states on transition metal impurity diffusion in TiN

- Ganesh Kumar Nayak

- , David Holec

- & Martin Zelený

Article 26 April 2023 | Open Access

Antagonistic fatigue crack acceleration/deceleration phenomena in Ni-based superalloy 718 under hydrogen-supply

- Osamu Takakuwa

- , Yuhei Ogawa

- & Ryunosuke Miyata

Article 25 April 2023 | Open Access

Prediction of 316 stainless steel low-cycle fatigue life based on machine learning

- Hongyan Duan

- , Mengjie Cao

- & Yang liu

Browse broader subjects

- Structural materials

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

- Career Paths

- Diversity, Equity, and Inclusion

- DMSE Job Opportunities

- Our Faculty

- Computing and Data Science

- Energy and the Environment

- Health and Medicine

- Manufacturing

- Transportation and Infrastructure

- Archaeological Materials

- Semiconductors

- Soft Matter

- Characterization

- Computation and Design

- Device Fabrication

- Synthesis and Processing

- Impact Stories

- Research Facilities

- Majors, Minors, and Concentration

- Opportunities For First-Year Students

- Opportunities for DMSE Undergraduates

- DMSE Breakerspace

- Wulff Lecture

- Application Assistance and Resources

- Doctoral Degree and Requirements

- Master’s Degree and Requirements

- Interdisciplinary Graduate Programs

- Funding Opportunities

- Postdoctoral Program

- MITx Online

- Newsletter Archive

- FORGE Initiative

Metal Matters

Metals have been a critical component of materials science for centuries. They are widely used in industries from aerospace to electronics to construction for their unique combination of properties, such as strength and electrical conductivity. Materials scientists and engineers study metals to better understand their properties and behavior and develop new materials that are stronger, more durable, and more efficient.

Another reason for studying metals is their potential for recycling and sustainability. Metals can be recovered from waste streams and reused, reducing the need for new materials and diminishing the environmental impact of production.

Most metals have high melting and boiling points.

Metals research at dmse.

DMSE started as the Department of Metallurgy and Mining, producing graduates whose work in ore refining and steel production led to an expansion of industry and transportation in the 19th century. Today, metals research at DMSE is focused on developing stronger alloys, more efficient manufacturing methods, and refining techniques that are less harmful to the environment.

To achieve these goals, DMSE researchers are using advanced computational methods to design and predict the properties of new metals before they are produced, enabling the development of alloys with customized properties for specific applications.

Related Research Types

Related faculty and researchers.

How hair deforms steel

What we did.

Discovered why stainless-steel blades lose their sharpness over time. We found that a single strand of hair can cause the blade to chip. These degradations are more likely to happen if the blade’s microstructure is not uniform or if the blade cuts hair at an angle.

Why we did it

Why it matters, microstructural and micro-mechanical characterization during hydrogen charging: an in situ scanning electron microscopy study.

Developed novel methods to study the influence of hydrogen on metallic materials.

Materials Science News

Top headlines, latest headlines.

- Building Blocks for Greener Energy

- Efficient Solid-State Lithium-Ion Batteries

- Cleaner Ammonia Production

- Are High-Purity Cathode Materials Necessary?

- Can Metalens Be Easily Commercialized?

- Power of Visible Light for Sustainable Chemistry

- Material Toughness and Crack Complexity

- Artificial Nose for Gas Sensing, Odor Detection

- Advancement in Nano-Processing

- Systemic Delivery of Cancer Immunotherapy

Earlier Headlines

Monday, april 1, 2024.

- Physics-Based Predictive Tool Will Speed Up Battery and Superconductor Research

Thursday, March 28, 2024

- Rapid Production of Isocyanate-Free, Biobased Polyurethane Foams at Ambient Temperature Is Now a Reality

Wednesday, March 27, 2024

- More Efficient TVs, Screens and Lighting

- Implantable Batteries Can Run on the Body's Own Oxygen

- Artificial Reef Designed by MIT Engineers Could Protect Marine Life, Reduce Storm Damage

Tuesday, March 26, 2024

- Bullseye! Accurately Centering Quantum Dots Within Photonic Chips

- New Method to Measure Entropy Production on the Nanoscale

- Silicon Spikes Take out 96% of Virus Particles

- Scientists on the Hunt for Evidence of Quantum Gravity's Existence at the South Pole

Monday, March 25, 2024

- Research Lights Up Process for Turning CO2 Into Sustainable Fuel

- With a New Experimental Technique, Engineers Probe the Mechanisms of Landslides and Earthquakes

- Scientists Deliver Quantum Algorithm to Develop New Materials and Chemistry

- A Self-Cleaning Wall Paint

- Rectifying AI's Usage in the Quest for Thermoelectric Materials

- New All-Liquid Iron Flow Battery for Grid Energy Storage

- Quantum Interference Could Lead to Smaller, Faster, and More Energy-Efficient Transistors

- New Reactor Could Save Millions When Making Ingredients for Plastics and Rubber from Natural Gas

- In-Situ Observation of Nanoscale Heat Propagation

- New Route to Recyclable Polymers from Plants

- Metamaterials and AI Converge, Igniting Innovative Breakthroughs

- Artificial Nanofluidic Synapses Can Store Computational Memory

Friday, March 22, 2024

- Bioelectronic Mesh Capable of Growing With Cardiac Tissues for Comprehensive Heart Monitoring

- Researchers Take Major Step Toward Developing Next-Generation Solar Cells

- Revolutionizing Hydrogen Production: Economical and Efficient Solutions Unveiled

Thursday, March 21, 2024

- Say Hello to Biodegradable Microplastics

- N-Channel Diamond Field-Effect Transistor

- Healing Eyes With Contact Lenses

Wednesday, March 20, 2024

- Cleaning Up Environmental Contaminants With Quantum Dot Technology

- Recyclable Reagent and Sunlight Convert Carbon Monoxide Into Methanol

- Robotic Metamaterial: An Endless Domino Effect

Tuesday, March 19, 2024

- Toxic Metal Particles Can Be Present in Cannabis Vapes Even Before the First Use, Study Finds

- Is Food Waste the Key to Sustainable, Plastic-Free Diapers and Sanitary Pads?

- Spectroscopy and Theory Shed Light on Excitons in Semiconductors

- Sustainable Solution for Wastewater Polluted by Dyes Used in Many Industries

- Bendable Energy Storage Materials by Cool Science

Monday, March 18, 2024

- Backyard Insect Inspires Invisibility Devices, Next Gen Tech

- Harnessing Hydrogen at Life's Origin

- Using Light to Produce Medication and Plastics More Efficiently

- Bridge in a Box: Unlocking Origami's Power to Produce Load-Bearing Structures

- Advance for Soft Robotics Manufacturing, Design

- Self-Heating Concrete Is One Step Closer to Putting Snow Shovels and Salt out of Business

- Engineers Measure pH in Cell Condensates

- Breakthrough in Melting Point Prediction: Over 100-Year-Old Physics Problem Solved

- Sustainable Plastics from Agricultural Waste

- Fast-Charging Lithium-Sulphur Batteries on the Horizon

Friday, March 15, 2024

- Printed Polymer Allows Researchers to Explore Chirality and Spin Interactions at Room Temperature

- Revolutionary Method Developed for Mass-Producing Polymer Solid Electrolytes

- Plasma Oscillations Propel Breakthroughs in Fusion Energy

- Breakthrough Could Make Automated Dosing Systems Universal

Thursday, March 14, 2024

- A New World of 2D Material Is Opening Up

- Perovskite Solar Cells: Vacuum Process May Offer a Short Track to Commercialization

- An Electricity Generator Inspired by the Drinking Bird Toy Powers Electronics With Evaporated Water

- How to Upcycle Low-Energy Light

Wednesday, March 13, 2024

- Scientists Use Novel Technique to Create New Energy-Efficient Microelectronic Device

- New High-Speed Microscale 3D Printing Technique

- Scientists Develop Ultra-Thin Semiconductor Fibers That Turn Fabrics Into Wearable Electronics

- 'Find Pearls in the Soil' Unveiling the Magic of Hydrogen Production from Municipal Sewage

- You Don't Need Glue to Hold These Materials Together -- Just Electricity

- Staying in the Loop: How Superconductors Are Helping Computers 'remember'

- Scientists Reveal the First Unconventional Superconductor That Can Be Found in Mineral Form in Nature

- Molecular Simulations of Ammonia Mixtures Support Search for Renewable Fuels

- New High-Performance Solar Cell Material

Tuesday, March 12, 2024

- Spiral Wrappers Switch Nanotubes from Conductors to Semiconductors and Back

- A Sprayable Gel Could Make Minimally Invasive Surgeries Simpler and Safer

- Powerful New Tool Ushers in New Era of Quantum Materials Research

- Have Metalenses Expanded Their Reach Into the Ultraviolet Region?

Monday, March 11, 2024

- A New Sensor Detects Harmful 'forever Chemicals' In Drinking Water

- Giving Particle Detectors a Boost

- GPS Nanoparticle Platform Precisely Delivers Therapeutic Payload to Cancer Cells

- Design Rules and Synthesis of Quantum Memory Candidates

- Breakthrough in Nanostructure Technology for Real-Time Color Display

- Preventing Magnet Meltdowns Before They Can Start

- Combined Microscopy Technique Catches Light-Driven Polymers in the Act

- Would the Highly Sensitive Transparent Ultrasound Transducer Revolutionize Biomedical Imaging Technology?

Friday, March 8, 2024

- How Surface Roughness Influences the Adhesion of Soft Materials

- Tiny Wireless Light Bulbs for Biomedical Applications

- Researchers Develop Artificial Building Blocks of Life

Thursday, March 7, 2024

- Shape-Shifting Ultrasound Stickers Detect Post-Surgical Complications

- Pinging Pipes Could Help to Identify Lead Water Lines Without Excavation

Wednesday, March 6, 2024

- Powerless Mechanoluminescent Touchscreen Underwater

- Viscose Manufactured Solely from Recycled Materials

- Making Quantum Bits Fly

- Healable Cathode Could Unlock Potential of Solid-State Lithium-Sulfur Batteries

Tuesday, March 5, 2024

- Key Advance Toward Removing Common Herbicide from Groundwater

- Aluminum Nanoparticles Make Tunable Green Catalysts

- Harmful 'forever Chemicals' Removed from Water With New Electrocatalysis Method

- Evolving Hydrogen-Storage Technology: Guidelines Developed for the Design of Anti-Evaporation Catalysts

- Using Light to Precisely Control Single-Molecule Devices

- New Method Measures the 3D Position of Individual Atoms

- Shortcut to Success: Toward Fast and Robust Quantum Control Through Accelerating Adiabatic Passage

- 'Like a Lab in Your Pocket' -- New Test Strips Raise Game in Gene-Based Diagnostics

- New Cardiovascular Imaging Approach Provides a Better View of Dangerous Plaques

- A New Theoretical Development Clarifies Water's Electronic Structure

Monday, March 4, 2024

- A Key to the Future of Robots Could Be Hiding in Liquid Crystals

- Researchers Use Liquid Crystals to Control Polarization Inside Laser-Written Waveguides

- Spontaneous Curvature the Key to Shape-Shifting Nanomaterials

Saturday, March 2, 2024

- Evolution-Capable AI Promotes Green Hydrogen Production Using More Abundant Chemical Elements

Friday, March 1, 2024

- Researchers Create Coating Solution for Safer Food Storage

- Unlocking the Potential of Lithium-Ion Batteries With Advanced Binders

- AI-Enabled Atomic Robotic Probe to Advance Quantum Material Manufacturing

- LATEST NEWS

- Top Science

- Top Physical/Tech

- Top Environment

- Top Society/Education

- Health & Medicine

- Mind & Brain

- Living Well

- Space & Time

- Matter & Energy

- Business & Industry

- Automotive and Transportation

- Consumer Electronics

- Energy and Resources

- Engineering and Construction

- Telecommunications

- Textiles and Clothing

- Biochemistry

- Inorganic Chemistry

- Organic Chemistry

- Thermodynamics

- Electricity

- Energy Technology

- Alternative Fuels

- Energy Policy

- Fossil Fuels

- Nuclear Energy

- Solar Energy

- Wind Energy

- Engineering

- 3-D Printing

- Civil Engineering

- Construction

- Electronics

- Forensic Research

- Materials Science

- Medical Technology

- Microarrays

- Nanotechnology

- Robotics Research

- Spintronics

- Sports Science

- Transportation Science

- Virtual Environment

- Weapons Technology

- Wearable Technology

- Albert Einstein

- Nature of Water

- Quantum Computing

- Quantum Physics

- Computers & Math

- Plants & Animals

- Earth & Climate

- Fossils & Ruins

- Science & Society

- Education & Learning

Strange & Offbeat

- Australia On Track for Decades-Long Megadroughts

- Speed of Visual Perception Ranges Widely

- 3D Printed Replica of an Adult Human Ear

- Extremely Fast Wound Healing: New Treatment

- Micro-Lisa! Novel Nano-Scale Laser Writing

- Simple Brain-Computer Link: Gaming With Thoughts

- Clinical Reasoning: Chatbot Vs Physicians

- Understanding People Who Can't Visualize

- Illuminating Oxygen's Journey in the Brain

- DNA Study IDs Descendants of George Washington

Trending Topics

- Research & Faculty

- Offices & Services

- Information for:

- Faculty & Staff

- News & Events

- Contact & Visit

- About the Department

- Message from the Chair

- Quick Facts

- Undergraduate Study

- Materials Science and Engineering (BS)

- Curriculum & Requirements

- Areas of Concentration

- ABET Objectives & Outcomes

- Minor in Materials Science

- Combined BS/MS Program

- Student Awards

- Hilliard Awards

- Outstanding MatSci Junior Award

- Outstanding MatSci Sophomore Award

- Meister Summer Awards

- Awards Application Information

- Special Programs

- Student Organizations

- Graduate Study

- Master of Science in Materials Science and Engineering

- Materials Science and Engineering (PhD)

- Financial Aid

- Admitted Students

- Previous Course Listings

- Areas of Research

- Art Conservation Science

- Biomaterials

- Magnetic Materials

- Materials for Electronics & Photonics

- Materials Synthesis and Processing

- Materials Theory, Computation, & Design

- Nanomaterials

- Self-Assembly

- Surfaces & Interfaces

- Affiliated Centers & Institutes

- Core Faculty

- Affiliated Faculty

- Research Faculty

- Emeritus Faculty

- Teaching Faculty

- Advisory Board

- Faculty Awards

- National Awards

- Northwestern Awards

- Professional Awards

- In Memoriam

- News Archive

- Colloquia & Seminars

- John E. Dorn Lecture

- John E. Hilliard Lecture & Symposium

- Morris E. Fine Lecture

- Dow Lecture

- Future Leaders Seminar Series

- Past Events

- Giving to MSE

- Department Resources

- Finance Resources

- Academic Resources

- Research Professor (Open Rank)

- Diversity, Equity, and Inclusion Committee

- Student Groups

- Past DEI Committee Members

- Future Leaders Program

- Current FLP Cohort

- Northwestern Engineering

Research / Areas of Research Metals

Metals fall between ceramics and polymers in terms of strength and temperature resistance, but have outstanding ductility and toughness, which make them particularly useful for structural, load-bearing applications.

Further non-structural applications take advantage of their unique electrical, magnetic, thermal, optical, and chemical properties.

Research Topics

Examples of metals research at Northwestern include:

- Shape-memory alloys for biomedical implants

- Multicomponent alloys for light-weight vehicles or high-temperature engines

- Intermetallic alloys for hydrogen storage

- Advanced characterization by electron microscopy or atom probe of alloys with nanoscale precipitates

- Yip-Wah Chung

- Vinayak Dravid

- David Dunand

- Laurence Marks

- David N. Seidman

- Peter Voorhees

- Chris Wolverton

More in this section

- Engineering Home

- MSE Department

Related Links

- Research at McCormick

- Meet Our Faculty

- Northwestern Research Overview

Contact Info

Department of Materials Science and Engineering McCormick School of Engineering and Applied Science 2220 Campus Drive, Room 2036 Evanston, IL 60208 Phone: 847-491-3537 Fax: 847-491-7820 Email Department

Suggestions or feedback?

MIT News | Massachusetts Institute of Technology

- Machine learning

- Social justice

- Black holes

- Classes and programs

Departments

- Aeronautics and Astronautics

- Brain and Cognitive Sciences

- Architecture

- Political Science

- Mechanical Engineering

Centers, Labs, & Programs

- Abdul Latif Jameel Poverty Action Lab (J-PAL)

- Picower Institute for Learning and Memory

- Lincoln Laboratory

- School of Architecture + Planning

- School of Engineering

- School of Humanities, Arts, and Social Sciences

- Sloan School of Management

- School of Science

- MIT Schwarzman College of Computing

Researchers unveil a secret of stronger metals

Press contact :, media download.

*Terms of Use:

Images for download on the MIT News office website are made available to non-commercial entities, press and the general public under a Creative Commons Attribution Non-Commercial No Derivatives license . You may not alter the images provided, other than to crop them to size. A credit line must be used when reproducing images; if one is not provided below, credit the images to "MIT."

Previous image Next image

Forming metal into the shapes needed for various purposes can be done in many ways, including casting, machining, rolling, and forging. These processes affect the sizes and shapes of the tiny crystalline grains that make up the bulk metal, whether it be steel, aluminum or other widely used metals and alloys.

Now researchers at MIT have been able to study exactly what happens as these crystal grains form during an extreme deformation process, at the tiniest scales, down to a few nanometers across. The new findings could lead to improved ways of processing to produce better, more consistent properties such as hardness and toughness.

The new findings, made possible by detailed analysis of images from a suite of powerful imaging systems, are reported today in the journal Nature Materials , in a paper by former MIT postdoc Ahmed Tiamiyu (now assistant professor at the University of Calgary); MIT professors Christopher Schuh, Keith Nelson, and James LeBeau; former student Edward Pang; and current student Xi Chen.

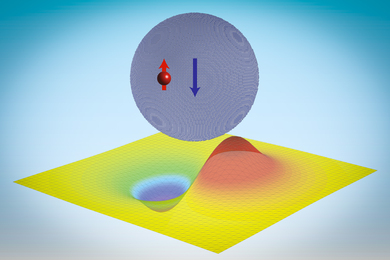

“In the process of making a metal, you are endowing it with a certain structure, and that structure will dictate its properties in service,” Schuh says. In general, the smaller the grain size, the stronger the resulting metal. Striving to improve strength and toughness by making the grain sizes smaller “has been an overarching theme in all of metallurgy, in all metals, for the past 80 years,” he says.

Metallurgists have long applied a variety of empirically developed methods for reducing the sizes of the grains in a piece of solid metal, generally by imparting various kinds of strain through deforming it in one way or another. But it’s not easy to make these grains smaller.

The primary method is called recrystallization, in which the metal is deformed and heated. This creates many small defects throughout the piece, which are “highly disordered and all over the place,” says Schuh, who is the Danae and Vasilis Salapatas Professor of Metallurgy.

When the metal is deformed and heated, then all those defects can spontaneously form the nuclei of new crystals. “You go from this messy soup of defects to freshly new nucleated crystals. And because they're freshly nucleated, they start very small,” leading to a structure with much smaller grains, Schuh explains.

What’s unique about the new work, he says, is determining how this process takes place at very high speed and the smallest scales. Whereas typical metal-forming processes like forging or sheet rolling, may be quite fast, this new analysis looks at processes that are “several orders of magnitude faster,” Schuh says.

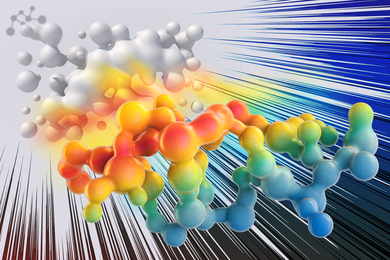

“We use a laser to launch metal particles at supersonic speeds. To say it happens in the blink of an eye would be an incredible understatement, because you could do thousands of these in the blink of an eye,” says Schuh.

Such a high-speed process is not just a laboratory curiosity, he says. “There are industrial processes where things do happen at that speed.” These include high-speed machining; high-energy milling of metal powder; and a method called cold spray, for forming coatings. In their experiments, “we’ve tried to understand that recrystallization process under those very extreme rates, and because the rates are so high, no one has really been able to dig in there and look systematically at that process before,” he says.

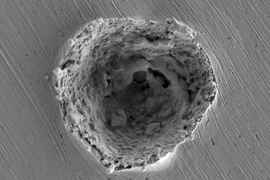

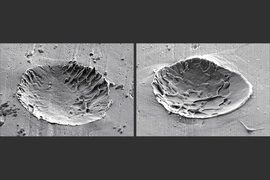

Using a laser-based system to shoot 10-micrometer particles at a surface, Tiamiyu, who carried out the experiments, “could shoot these particles one at a time, and really measure how fast they are going and how hard they hit,” Schuh says. Shooting the particles at ever-faster speeds, he would then cut them open to see how the grain structure evolved, down to the nanometer scale, using a variety of sophisticated microscopy techniques at the MIT.nano facility, in collaboration with microscopy specialists.

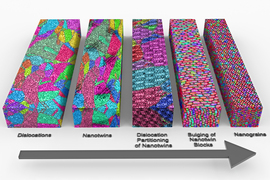

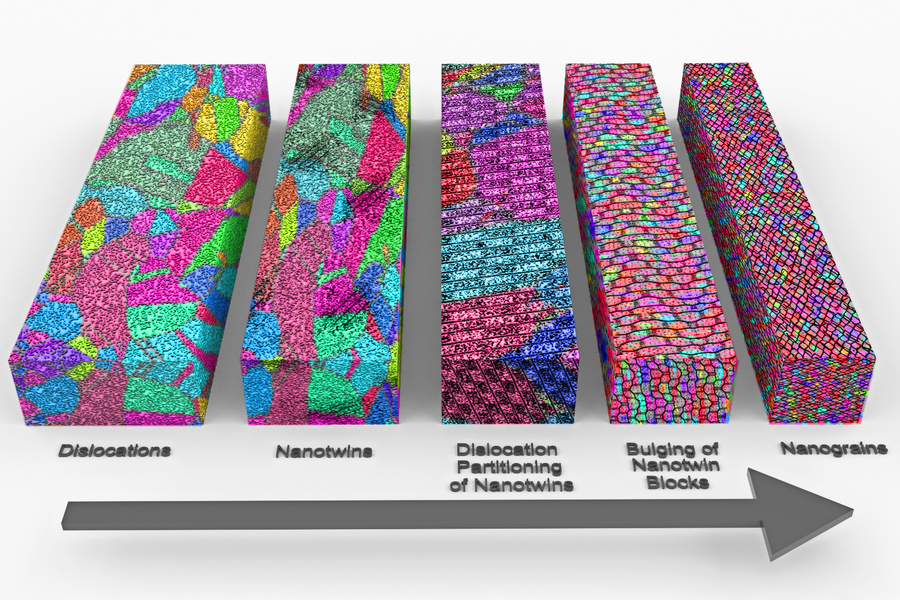

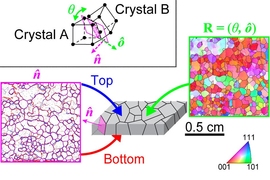

The result was the discovery of what Schuh says is a “novel pathway” by which grains were forming down to the nanometer scale. The new pathway, which they call nano-twinning assisted recrystallization, is a variation of a known phenomenon in metals called twinning, a particular kind of defect in which part of the crystalline structure flips its orientation. It’s a “mirror symmetry flip, and you end up getting these stripey patterns where the metal flips its orientation and flips back again, like a herringbone pattern,” he says. The team found that the higher the rate of these impacts, the more this process took place, leading to ever smaller grains as those nanoscale “twins” broke up into new crystal grains.

In the experiments they did using copper, the process of bombarding the surface with these tiny particles at high speed could increase the metal’s strength about tenfold. “This is not a small change in properties,” Schuh says, and that result is not surprising since it’s an extension of the known effect of hardening that comes from the hammer blows of ordinary forging. “This is sort of a hyper-forging type of phenomenon that we’re talking about.”

In the experiments, they were able to apply a wide range of imaging and measurements to the exact same particles and impact sites, Schuh says: “So, we end up getting a multimodal view. We get different lenses on the same exact region and material, and when you put all that together, you have just a richness of quantitative detail about what’s going on that a single technique alone wouldn't provide.”

Because the new findings provide guidance about the degree of deformation needed, how fast that deformation takes place, and the temperatures to use for maximum effect for any given specific metals or processing methods, they can be directly applied right away to real-world metals production, Tiamiyu says. The graphs they produced from the experimental work should be generally applicable. “They’re not just hypothetical lines,” Tiamiyu says. For any given metals or alloys, “if you’re trying to determine if nanograins will form, if you have the parameters, just slot it in there” into the formulas they developed, and the results should show what kind of grain structure can be expected from given rates of impact and given temperatures.

The research was supported by the U.S. Department of Energy, the Office of Naval Research, and the Natural Sciences and Engineering Research Council of Canada.

Share this news article on:

Related links.

- Christopher Schuh

- Department of Materials Science and Engineering

Related Topics

- Materials science and engineering

- Nanoscience and nanotechnology

Related Articles

Researchers find a better way to design metal alloys

What happens when materials take tiny hits

How to get sprayed metal coatings to stick

New technique provides detailed views of metals’ crystal structure

Faculty highlight: Christopher Schuh

Previous item Next item

More MIT News

A new computational technique could make it easier to engineer useful proteins

Read full story →

MIT researchers discover “neutronic molecules”

Training manufacturing technologists to be future shop floor leaders

Characterizing social networks

Designing solutions to ensure equity in health care

MIT economics to launch new predoctoral fellowship program

- More news on MIT News homepage →

Massachusetts Institute of Technology 77 Massachusetts Avenue, Cambridge, MA, USA

- Map (opens in new window)

- Events (opens in new window)

- People (opens in new window)

- Careers (opens in new window)

- Accessibility

- Social Media Hub

- MIT on Facebook

- MIT on YouTube

- MIT on Instagram

IMAGES

VIDEO

COMMENTS

Metals and alloys articles from across Nature Portfolio. Metals and alloys are materials that are typically hard, malleable, and have good electrical and thermal conductivity. Alloys are made...

Metals articles from across Nature Portfolio. Metals are electropositive chemical elements, and as such have a propensity to form cations, which they are found as – often bound in ...

Read the latest Research articles in Metals and alloys from Scientific Reports.

Today, metals research at DMSE is focused on developing stronger alloys, more efficient manufacturing methods, and refining techniques that are less harmful to the environment.

Mar. 28, 2024 — Researchers suggests a groundbreaking strategy to expedite the commercialization of metalens ... Study Unlocks the Power of Visible Light for Sustainable Chemistry. Mar. 28, 2024 —...

Researchers have found a new way to predict the properties of metal alloys based on reactions at the boundaries between the crystalline grains of the primary metal. In this image, the colored dots indicate the likelihood that atoms will collect along these boundaries rather than penetrating through.

Examples of metals research at Northwestern include: Shape-memory alloys for biomedical implants. Multicomponent alloys for light-weight vehicles or high-temperature engines. Intermetallic alloys for hydrogen storage. Advanced characterization by electron microscopy or atom probe of alloys with nanoscale precipitates.

Caption. For the first time, researchers have described how the tiny crystalline grains that make up most solid metals actually form. Understanding this process, they say, could theoretically lead to ways of producing stronger, lighter versions of widely used metals such as aluminum, steel and titanium. Credits. Image: Courtesy of the researchers.