- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

What Really Makes Toyota’s Production System Resilient

- Willy C. Shih

“Just-in-time” only works as part of a comprehensive suite of strategies.

Toyota has fared better than many of its competitors in riding out the supply chain disruptions of recent years. But focusing on how Toyota had stockpiled semiconductors and the problems of other manufacturers, some observers jumped to the conclusion that the era of the vaunted Toyota Production System was over. Not the case, say Toyota executives. TPS is alive and well and is a key reason Toyota has outperformed rivals.

The supply chain disruptions triggered by the Covid-19 pandemic caused major headaches for manufacturers around the world. Nowhere was this felt more acutely than in the auto industry, which faced severe shortages of semiconductor chips and other components. This led many people to argue that just-in-time and lean production methods were dead and being superseded by “just-in-case” stocking of more inventory.

- Willy C. Shih is a Baker Foundation Professor of Management Practice at Harvard Business School.

Partner Center

THE ESSENCE OF JUST-IN-TIME: PRACTICE-IN-USE AT TOYOTA PRODUCTION SYSTEM MANAGED ORGANIZATIONS - How Toyota Turns Workers Into Problem Solvers

by Sarah Jane Johnston, HBS Working Knowledge

When HBS professor Steven Spear recently released an abstract on problem solving at Toyota, HBS Working Knowledge staffer Sarah Jane Johnston e-mailed off some questions. Spear not only answered the questions, but also asked some of his own—and answered those as well.

Sarah Jane Johnston: Why study Toyota? With all the books and articles on Toyota, lean manufacturing, just-in-time, kanban systems, quality systems, etc. that came out in the 1980s and 90s, hasn't the topic been exhausted?

Steven Spear: Well, this has been a much-researched area. When Kent Bowen and I first did a literature search, we found nearly 3,000 articles and books had been published on some of the topics you just mentioned.

However, there was an apparent discrepancy. There had been this wide, long-standing recognition of Toyota as the premier automobile manufacturer in terms of the unmatched combination of high quality, low cost, short lead-time and flexible production. And Toyota's operating system—the Toyota Production System—had been widely credited for Toyota's sustained leadership in manufacturing performance. Furthermore, Toyota had been remarkably open in letting outsiders study its operations. The American Big Three and many other auto companies had done major benchmarking studies, and they and other companies had tried to implement their own forms of the Toyota Production System. There is the Ford Production System, the Chrysler Operating System, and General Motors went so far as to establish a joint venture with Toyota called NUMMI, approximately fifteen years ago.

However, despite Toyota's openness and the genuinely honest efforts by other companies over many years to emulate Toyota, no one had yet matched Toyota in terms of having simultaneously high-quality, low-cost, short lead-time, flexible production over time and broadly based across the system.

It was from observations such as these that Kent and I started to form the impression that despite all the attention that had already been paid to Toyota, something critical was being missed. Therefore, we approached people at Toyota to ask what they did that others might have missed.

What did they say?

To paraphrase one of our contacts, he said, "It's not that we don't want to tell you what TPS is, it's that we can't. We don't have adequate words for it. But, we can show you what TPS is."

Over about a four-year period, they showed us how work was actually done in practice in dozens of plants. Kent and I went to Toyota plants and those of suppliers here in the U.S. and in Japan and directly watched literally hundreds of people in a wide variety of roles, functional specialties, and hierarchical levels. I personally was in the field for at least 180 working days during that time and even spent one week at a non-Toyota plant doing assembly work and spent another five months as part of a Toyota team that was trying to teach TPS at a first-tier supplier in Kentucky.

What did you discover?

We concluded that Toyota has come up with a powerful, broadly applicable answer to a fundamental managerial problem. The products we consume and the services we use are typically not the result of a single person's effort. Rather, they come to us through the collective effort of many people each doing a small part of the larger whole. To a certain extent, this is because of the advantages of specialization that Adam Smith identified in pin manufacturing as long ago as 1776 in The Wealth of Nations . However, it goes beyond the economies of scale that accrue to the specialist, such as skill and equipment focus, setup minimization, etc.

The products and services characteristic of our modern economy are far too complex for any one person to understand how they work. It is cognitively overwhelming. Therefore, organizations must have some mechanism for decomposing the whole system into sub-system and component parts, each "cognitively" small or simple enough for individual people to do meaningful work. However, decomposing the complex whole into simpler parts is only part of the challenge. The decomposition must occur in concert with complimentary mechanisms that reintegrate the parts into a meaningful, harmonious whole.

This common yet nevertheless challenging problem is obviously evident when we talk about the design of complex technical devices. Automobiles have tens of thousands of mechanical and electronic parts. Software has millions and millions of lines of code. Each system can require scores if not hundreds of person-work-years to be designed. No one person can be responsible for the design of a whole system. No one is either smart enough or long-lived enough to do the design work single handedly.

Furthermore, we observe that technical systems are tested repeatedly in prototype forms before being released. Why? Because designers know that no matter how good their initial efforts, they will miss the mark on the first try. There will be something about the design of the overall system structure or architecture, the interfaces that connect components, or the individual components themselves that need redesign. In other words, to some extent the first try will be wrong, and the organization designing a complex system needs to design, test, and improve the system in a way that allows iterative congruence to an acceptable outcome.

The same set of conditions that affect groups of people engaged in collaborative product design affect groups of people engaged in the collaborative production and delivery of goods and services. As with complex technical systems, there would be cognitive overload for one person to design, test-in-use, and improve the work systems of factories, hotels, hospitals, or agencies as reflected in (a) the structure of who gets what good, service, or information from whom, (b) the coordinative connections among people so that they can express reliably what they need to do their work and learn what others need from them, and (c) the individual work activities that create intermediate products, services, and information. In essence then, the people who work in an organization that produces something are simultaneously engaged in collaborative production and delivery and are also engaged in a collaborative process of self-reflective design, "prototype testing," and improvement of their own work systems amidst changes in market needs, products, technical processes, and so forth.

It is our conclusion that Toyota has developed a set of principles, Rules-in-Use we've called them, that allow organizations to engage in this (self-reflective) design, testing, and improvement so that (nearly) everyone can contribute at or near his or her potential, and when the parts come together the whole is much, much greater than the sum of the parts.

What are these rules?

We've seen that consistently—across functional roles, products, processes (assembly, equipment maintenance and repair, materials logistics, training, system redesign, administration, etc.), and hierarchical levels (from shop floor to plant manager and above) that in TPS managed organizations the design of nearly all work activities, connections among people, and pathways of connected activities over which products, services, and information take form are specified-in-their-design, tested-with-their-every-use, and improved close in time, place, and person to the occurrence of every problem.

That sounds pretty rigorous.

It is, but consider what the Toyota people are attempting to accomplish. They are saying before you (or you all) do work, make clear what you expect to happen (by specifying the design), each time you do work, see that what you expected has actually occurred (by testing with each use), and when there is a difference between what had actually happened and what was predicted, solve problems while the information is still fresh.

That reminds me of what my high school lab science teacher required.

Exactly! This is a system designed for broad based, frequent, rapid, low-cost learning. The "Rules" imply a belief that we may not get the right solution (to work system design) on the first try, but that if we design everything we do as a bona fide experiment, we can more rapidly converge, iteratively, and at lower cost, on the right answer, and, in the process, learn a heck of lot more about the system we are operating.

You say in your article that the Toyota system involves a rigorous and methodical problem-solving approach that is made part of everyone's work and is done under the guidance of a teacher. How difficult would it be for companies to develop their own program based on the Toyota model?

Your question cuts right to a critical issue. We discussed earlier the basic problem that for complex systems, responsibility for design, testing, and improvement must be distributed broadly. We've observed that Toyota, its best suppliers, and other companies that have learned well from Toyota can confidently distribute a tremendous amount of responsibility to the people who actually do the work, from the most senior, expeirenced member of the organization to the most junior. This is accomplished because of the tremendous emphasis on teaching everyone how to be a skillful problem solver.

How do they do this?

They do this by teaching people to solve problems by solving problems. For instance, in our paper we describe a team at a Toyota supplier, Aisin. The team members, when they were first hired, were inexperienced with at best an average high school education. In the first phase of their employment, the hurdle was merely learning how to do the routine work for which they were responsible. Soon thereafter though, they learned how to immediately identify problems that occurred as they did their work. Then they learned how to do sophisticated root-cause analysis to find the underlying conditions that created the symptoms that they had experienced. Then they regularly practiced developing counter-measures—changes in work, tool, product, or process design—that would remove the underlying root causes.

Sounds impressive.

Yes, but frustrating. They complained that when they started, they were "blissful in their ignorance." But after this sustained development, they could now see problems, root down to their probable cause, design solutions, but the team members couldn't actually implement these solutions. Therefore, as a final round, the team members received training in various technical crafts—one became a licensed electrician, another a machinist, another learned some carpentry skills.

Was this unique?

Absolutely not. We saw the similar approach repeated elsewhere. At Taiheiyo, another supplier, team members made sophisticated improvements in robotic welding equipment that reduced cost, increased quality, and won recognition with an award from the Ministry of Environment. At NHK (Nippon Spring) another team conducted a series of experiments that increased quality, productivity, and efficiency in a seat production line.

What is the role of the manager in this process?

Your question about the role of the manager gets right to the heart of the difficulty of managing this way. For many people, it requires a profound shift in mind-set in terms of how the manager envisions his or her role. For the team at Aisin to become so skilled as problem solvers, they had to be led through their training by a capable team leader and group leader. The team leader and group leader were capable of teaching these skills in a directed, learn-by-doing fashion, because they too were consistently trained in a similar fashion by their immediate senior. We found that in the best TPS-managed plants, there was a pathway of learning and teaching that cascaded from the most senior levels to the most junior. In effect, the needs of people directly touching the work determined the assistance, problem solving, and training activities of those more senior. This is a sharp contrast, in fact a near inversion, in terms of who works for whom when compared with the more traditional, centralized command and control system characterized by a downward diffusion of work orders and an upward reporting of work status.

And if you are hiring a manager to help run this system, what are the attributes of the ideal candidate?

We observed that the best managers in these TPS managed organizations, and the managers in organizations that seem to adopt the Rules-in-Use approach most rapidly are humble but also self-confident enough to be great learners and terrific teachers. Furthermore, they are willing to subscribe to a consistent set of values.

How do you mean?

Again, it is what is implied in the guideline of specifying every design, testing with every use, and improving close in time, place, and person to the occurrence of every problem. If we do this consistently, we are saying through our action that when people come to work, they are entitled to expect that they will succeed in doing something of value for another person. If they don't succeed, they are entitled to know immediately that they have not. And when they have not succeeded, they have the right to expect that they will be involved in creating a solution that makes success more likely on the next try. People who cannot subscribe to these ideas—neither in their words nor in their actions—are not likely to manage effectively in this system.

That sounds somewhat high-minded and esoteric.

I agree with you that it strikes the ear as sounding high principled but perhaps not practical. However, I'm fundamentally an empiricist, so I have to go back to what we have observed. In organizations in which managers really live by these Rules, either in the Toyota system or at sites that have successfully transformed themselves, there is a palpable, positive difference in the attitude of people that is coupled with exceptional performance along critical business measures such as quality, cost, safety, and cycle time.

Have any other research projects evolved from your findings?

We titled the results of our initial research "Decoding the DNA of the Toyota Production System." Kent and I are reasonably confident that the Rules-in-Use about which we have written are a successful decoding. Now, we are trying to "replicate the DNA" at a variety of sites. We want to know where and when these Rules create great value, and where they do, how they can be implemented most effectively.

Since we are empiricists, we are conducting experiments through our field research. We are part of a fairly ambitious effort at Alcoa to develop and deploy the Alcoa Business System, ABS. This is a fusion of Alcoa's long standing value system, which has helped make Alcoa the safest employer in the country, with the Rules in Use. That effort has been going on for a number of years, first with the enthusiastic support of Alcoa's former CEO, Paul O'Neill, now Secretary of the Treasury (not your typical retirement, eh?) and now with the backing of Alain Belda, the company's current head. There have been some really inspirational early results in places as disparate as Hernando, Mississippi and Poces de Caldas, Brazil and with processes as disparate as smelting, extrusion, die design, and finance.

We also started creating pilot sites in the health care industry. We started our work with a "learning unit" at Deaconess-Glover Hospital in Needham, not far from campus. We've got a series of case studies that captures some of the learnings from that effort. More recently, we've established pilot sites at Presbyterian and South Side Hospitals, both part of the University of Pittsburgh Medical Center. This work is part of a larger, comprehensive effort being made under the auspices of the Pittsburgh Regional Healthcare Initiative, with broad community support, with cooperation from the Centers for Disease Control, and with backing from the Robert Wood Johnson Foundation.

Also, we've been testing these ideas with our students: Kent in the first year Technology and Operations Management class for which he is course head, me in a second year elective called Running and Growing the Small Company, and both of us in an Executive Education course in which we participate called Building Competitive Advantage Through Operations.

· · · ·

Steven Spear is an Assistant Professor in the Technology and Operations Management Unit at the Harvard Business School.

Other HBS Working Knowledge stories featuring Steven J. Spear: Decoding the DNA of the Toyota Production System Why Your Organization Isn't Learning All It Should

Developing Skillful Problem Solvers: Introduction

Within TPS-managed organizations, people are trained to improve the work that they perform, they learn to do this with the guidance of a capable supplier of assistance and training, and training occurs by solving production and delivery-related problems as bona fide, hypothesis-testing experiments. Examples of this approach follow.

- A quality improvement team at a Toyota supplier, Taiheiyo, conducted a series of experiments to eliminate the spatter and fumes emitted by robotic welders. The quality circle members, all line workers, conducted a series of complex experiments that resulted in a cleaner, safer work environment, equipment that operated with less cost and higher reliability, and relief for more technically-skilled maintenance and engineering specialists from basic equipment maintenance and repair.

- A work team at NHK (Nippon Spring) Toyota, were taught to conduct a series of experiments over many months to improve the process by which arm rest inserts were "cold molded." The team reduced the cost, shortened the cycle time, and improved the quality while simultaneously developing the capability to take a similar experimental approach to process improvement in the future.

- At Aisin, a team of production line workers progressed from having the skills to do only routine production work to having the skills to identify problems, investigate root causes, develop counter-measures, and reconfigure equipment as skilled electricians and machinists. This transformation occurred primarily through the mechanism of problem solving-based training.

- Another example from Aisin illustrates how improvement efforts—in this case of the entire production system by senior managers—were conducted as a bona fide hypothesis-refuting experiment.

- The Acme and Ohba examples contrast the behavior of managers deeply acculturated in Toyota with that of their less experienced colleagues. The Acme example shows the relative emphasis one TPS acculturated manager placed on problem solving as a training opportunity in comparison to his colleagues who used the problem-solving opportunity as a chance to first make process improvements. An additional example from a Toyota supplier reinforces the notion of using problem solving as a vehicle to teach.

- The data section concludes with an example given by a former employee of two companies, both of which have been recognized for their efforts to be a "lean manufacturer" but neither of which has been trained in Toyota's own methods. The approach evident at Toyota and its suppliers was not evident in this person's narrative.

Defining conditions as problematic

We concluded that within Toyota Production System-managed organizations three sets of conditions are considered problematic and prompt problem-solving efforts. These are summarized here and are discussed more fully in a separate paper titled "Pursuing the IDEAL: Conditions that Prompt Problem Solving in Toyota Production System-Managed Organizations."

Failure to meet a customer need

It was typically recognized as a problem if someone was unable to provide the good, service, or information needed by an immediate or external customer.

Failure to do work as designed

Even if someone was able to meet the need of his or her customers without fail (agreed upon mix, volume, and timing of goods and services), it was typically recognized as a problem if a person was unable to do his or her own individual work or convey requests (i.e., "Please send me this good or service that I need to do my work.") and responses (i.e., "Here is the good or service that you requested, in the quantity you requested.").

Failure to do work in an IDEAL fashion

Even if someone could meet customer needs and do his or her work as designed, it was typically recognized as a problem if that person's work was not IDEAL. IDEAL production and delivery is that which is defect-free, done on demand, in batches of one, immediate, without waste, and in an environment that is physically, emotionally, and professionally safe. The improvement activities detailed in the cases that follow, the reader will see, were motivated not so much by a failure to meet customer needs or do work as designed. Rather, they were motivated by costs that were too high (i.e., Taiheiyo robotic welding operation), batch sizes that were too great (i.e., the TSSC improvement activity evaluated by Mr. Ohba), lead-times that were too long, processes that were defect-causing (i.e., NHK cold-forming process), and by compromises to safety (i.e., Taiheiyo).

Our field research suggests that Toyota and those of its suppliers that are especially adroit at the Toyota Production System make a deliberate effort to develop the problem-solving skills of workers—even those engaged in the most routine production and delivery. We saw evidence of this in the Taiheiyo, NHK, and Aisin quality circle examples.

Forums are created in which problem solving can be learned in a learn-by-doing fashion. This point was evident in the quality circle examples. It was also evident to us in the role played by Aisin's Operations Management Consulting Division (OMCD), Toyota's OMCD unit in Japan, and Toyota's Toyota Supplier Support Center (TSSC) in North America. All of these organizations support the improvement efforts of the companies' factories and those of the companies' suppliers. In doing so, these organizations give operating managers opportunities to hone their problem-solving and teaching skills, relieved temporarily of day to day responsibility for managing, production and delivery of goods and services to external customers.

Learning occurs with the guidance of a capable teacher. This was evident in that each of the quality circles had a specific group leader who acted as coach for the quality circle's team leader. We also saw how Mr. Seto at NHK defined his role as, in part, as developing the problem-solving and teaching skills of the team leader whom he supervised.

Problem solving occurs as bona fide experiments. We saw this evident in the experience of the quality circles who learned to organize their efforts as bona fide experiments rather than as ad hoc attempts to find a feasible, sufficient solution. The documentation prepared by the senior team at Aisin is organized precisely to capture improvement ideas as refutable hypotheses.

Broadly dispersed scientific problem solving as a dynamic capability

Problem solving, as illustrated in this paper, is a classic example of a dynamic capability highlighted in the "resource-based" view of the firm literature.

Scientific problem solving—as a broadly dispersed skill—is time consuming to develop and difficult to imitate. Emulation would require a similar investment in time, and, more importantly, in managerial resources available to teach, coach, assist, and direct. For organizations currently operating with a more traditional command and control approach, allocating such managerial resources would require more than a reallocation of time across a differing set of priorities. It would also require an adjustment of values and the processes through which those processes are expressed. Christensen would argue that existing organizations are particularly handicapped in making such adjustments.

Excerpted with permission from "Developing Skillful Problem Solvers in Toyota Production System-Managed Organizations: Learning to Problem Solve by Solving Problems," HBS Working Paper , 2001.

Why Toyota’s Just-in-Time Method Is Critical to Its Success

Toyota began using the Just-in-Time method in 1938. However, the true potential of this strategy was realized when it integrated this strategy with TPS.

May 30 2016, Updated 11:08 a.m. ET

Toyota’s Just-in-Time method

The automotive industry is highly capital-intensive in nature. This is the driving reason behind efforts by automakers (XLY) to employ cost-effective business strategies to minimize their costs. The Toyota Production System (or TPS) is one of the most notable business strategies utilized by the automaker.

The Just-in-Time (or JIT) method is an integral part of this strategy. In this part of the series, we’ll explore how Toyota’s (TM) Just-in-Time method evolved and helps the company to minimize its costs.

Evolution of the Toyota Production System

After World War II, the majority of Japanese companies, including automakers, were facing challenges and struggling to survive. At the time, a sharp decline in auto demand and the high costs of production haunted automakers, including Toyota.

Toyota began using the Just-in-Time method in 1938. However, the true potential of this strategy was realized when it integrated this strategy with TPS. The company notes that this system was based on the concept of “the complete elimination of all waste.”

According to the company, “The TPS has evolved through many years of trial and error to improve efficiency based on the Just-in-Time concept developed by Kiichiro Toyoda, the founder of Toyota.” Additionally, a former Toyota vice president, Taiichi Ohno, is also associated with TPS. Ohno helped Toyota in creating the basic framework for the JIT method.

The company describes JIT as “making only what is needed, when it is needed, and in the amount needed.”

How does it work?

Using JIT, Toyota produces its vehicles based on the orders it receives through its dealers. In this production process, the company uses its supply chain in such a manner that only the parts that are needed to manufacture vehicles are received on time. Thus, the manufacturing and transportation of parts take place simultaneously. This allows Toyota to minimize its inventory of vehicle parts.

JIT also emphasizes the importance of work efficiency. According to Toyota’s website, the “use of JIT within the Toyota Production System means that individual cars can be built to order and that every component has to fit perfectly first time because there are no alternatives available.”

Notably, TPS has become very popular globally. It is also used by companies such as Hewlett-Packard (HPQ) , Motorola (MSI) , and General Electric (GE) .

Now, let’s take a look at Toyota’s marketing strategy.

Latest HP Inc News and Updates

- ABOUT Market Realist

- Privacy Policy

- Terms of Use

- CONNECT with Market Realist

- Link to Facebook

- Link to Instagram

- Contact us by Email

Opt-out of personalized ads

© Copyright 2024 Market Realist. Market Realist is a registered trademark. All Rights Reserved. People may receive compensation for some links to products and services on this website. Offers may be subject to change without notice.

- How Toyota's Just-In-Time (JIT) System Revolutionized Manufacturing

When one thinks of groundbreaking innovations in manufacturing, Toyota's Just-In-Time (JIT) system undoubtedly stands out. Born out of necessity and refined through careful observation and relentless pursuit of efficiency, the JIT system has not only transformed Toyota's operations but has also left an indelible mark on the global manufacturing landscape. Let's delve into this game-changing philosophy.

1. The Birth of JIT

Post-World War II Japan was resource-scarce. With limited space for inventory and a pressing need for diversified automobile production, Toyota faced a challenge. Traditional mass production methods, epitomized by companies like Ford, weren't feasible. Thus, under the guidance of Taiichi Ohno, the company began to develop a system where parts were produced only when needed and in the exact quantities required.

2. JIT Defined

At its essence, JIT is about producing the right item, in the right amount, at the right time. This system minimizes waste by drastically reducing inventory and streamlining production processes.

3. Pillars of JIT

- Kanban System: Serving as the linchpin of JIT, the Kanban system uses cards (or other signaling methods) to indicate when a particular component should be produced or supplied. As products move through the production line, Kanban signals ensure that parts are replenished only when consumed.

- Takt Time: This refers to the maximum amount of time allowed to produce a product to meet customer demand. It helps synchronize production processes, ensuring a smooth, efficient flow.

- Leveling: By spreading production evenly and minimizing fluctuations, Toyota can efficiently allocate resources, reducing downtime and bottlenecks.

4. The Benefits Realized

Toyota's adoption of JIT led to various benefits:

- Reduced Inventory Costs: Large inventories tie up capital and occupy space. By minimizing inventory, Toyota significantly cut storage and handling costs.

- Improved Quality: With a focus on real-time production, defects were detected and addressed promptly, enhancing product quality.

- Flexibility: JIT allowed Toyota to adapt swiftly to changes in market demand, offering a diverse range of models without maintaining vast inventories of each.

5. The Global Ripple Effect

Toyota's success didn't remain a Japanese secret for long. As companies worldwide noted Toyota's efficiency and profitability, they sought to understand the magic behind the scenes. The JIT system, with its undeniable benefits, became a sought-after model:

- Manufacturing: Beyond automobiles, sectors like electronics, aerospace, and consumer goods started to adopt JIT principles, aiming to optimize their processes and reduce waste.

- Supply Chain Management: The JIT philosophy redefined supply chain dynamics, emphasizing partnerships, real-time communication, and synchronized deliveries.

- Lean Manufacturing: JIT principles became foundational to the broader "Lean" philosophy, emphasizing waste reduction and value optimization throughout the production process.

6. Challenges Along the Way

JIT, while transformative, isn't without its challenges. It demands precise coordination, real-time communication, and a high degree of trust among all stakeholders. Any disruption, whether from supplier delays, natural disasters, or geopolitical issues, can have significant repercussions.

7. The Legacy of JIT in the Digital Age

With advancements in technology, particularly the Internet of Things (IoT), Artificial Intelligence (AI), and advanced analytics, the JIT system is evolving. Real-time data, predictive analytics, and smart factories are enhancing JIT's principles, offering even more refined levels of efficiency and responsiveness.

Toyota's Just-In-Time system is a testament to the power of innovation born from necessity. It's a story of how keen observation, a deep understanding of processes, and the courage to challenge conventional wisdom can lead to revolutionary outcomes. In the annals of manufacturing history, JIT stands as a beacon, illuminating the path to efficiency, responsiveness, and quality.

Related Posts

- First American President of Toyota Motor Manufacturing - Given that the Toyota Way is to make decisions slowly, thoroughly considering alternatives (see Make Decisions Slowly by Consensus,Thoroughly Considering All Options; Implement Rapidly (Nemawashi) on nemawashi), it was not...

- Creating the Manufacturing System That Changed the World - In the 1950s, Ohno returned to the place he understood best, the shop floor, and went to work to change the rules of the game. He did not have a...

- The Essence of Toyota Management System - Table of Contents The History and Evolution of TMS The Core Principles of TMS Practices & Techniques Modern Adaptations of TMS The Future of TMS In the world of management,...

- Key Principles of Toyota Production System (TPS) - The Toyota Production System (TPS) is a renowned philosophy that has transformed the manufacturing industry. It's not just a method or a process but a culture, one that prioritizes efficiency,...

- Using the Toyota Way to Transform Technical and Service Organizations - Applying the Toyota Production System outside the shop floor can be done, but this takes some creativity. Certainly, the basic principles can be applied to administrative processes. We sent some...

- The Toyota Way Is More than Tools and Techniques - So you set up your kanban system. (Kanban is the Japanese word for “card,” “ticket,” or “sign” and is a tool for managing the flow and production of materials in...

- Using the Toyota Way for Long-Term Success - Critics often describe Toyota as a “boring company.” This is the kind of boring I like. Top quality year in and year out. Steadily growing sales. Consistent profitability. Huge cash...

- The 14 Principles of the Toyota Way - The Toyota Way, a management philosophy that has propelled Toyota to its current position as a global leader in efficiency and quality, is underpinned by 14 key principles. These principles...

- The Origins of the Toyota Management System - The Toyota Management System (TMS), often interchangeably referred to as the Toyota Production System (TPS), is an iconic example of innovation and operational efficiency. Its impact resonates beyond the automobile...

- Understanding the Toyota Way - For many organizations, the pursuit of efficiency, productivity, and quality has always been paramount. Yet, only a few have managed to achieve a reputation quite like Toyota, the Japanese automotive...

- Toyota's Global Expansion: Strategies and Challenges

- Toyota's Cross-cultural Communication Strategies in Global Operations

- Toyota's Approach to Quality Management: Tools and Techniques

- Toyota Logistics Operation

- Toyota's Supplier Relationship Management: Building Long-Term Partnerships

- Toyota's Joint Ventures and Strategic Alliances

- Toyota's Six Sigma Approach and Its Implementation

- Toyota's Digital Transformation in Manufacturing

- Toyota's Corporate Social Responsibility Initiatives

(Stanford users can avoid this Captcha by logging in.)

- Send to text email RefWorks EndNote printer

Toyota Production System : an integrated approach to Just-In-Time

Available online.

- Safari Books Online

More options

- Find it at other libraries via WorldCat

- Contributors

Description

Creators/contributors, contents/summary.

- Total Framework of the Toyota Production System Primary Purpose Kanban System Production Smoothing Shortening Setup Time Process Layout for Shortened Lead Times Standardization of Operations Autonomation Improvement Activities The Goal of TPS Summary

- Implementation Steps for the Toyota Production System Introductory Steps to the Toyota Production System Introduction of JIT at Toyo Aluminum- A Case Study SUBSYSTEMs

- Adaptable Kanban System Maintains Just-In-Time Production Pull System for JIT Production What Is a Kanban? Kanban Rules Other Types of Kanban

- Supplier Kanban and the Sequence Schedule Used by Suppliers Monthly Information and Daily Information Later Replenishment System by Kanban Sequenced Withdrawal System by the Sequence Schedule Problems and Countermeasures in Applying the Kanban System to Subcontractors Guidance by the Fair Trade Commission Based on the Subcontractors Law and the Anti-monopoly Law Supplier Kanban Circulation in the Paternal Manufacturer Practical Examples of Delivery System and Delivery Cycle

- Smoothed Production Helps Toyota Adapt to Demand Changes and Reduce Inventory Smoothing of the Total Production Quantity Demand Fluctuation and Production Capacity Plan Smoothing Each Model's Production Quantity Comparison of the Kanban System with MRP Summary of the Concept of Production Smoothing

- The Information System for Supply Chain Management between Toyota, Its Dealers, and Parts Manufacturers The Order Entry Information System Monthly Production System The Information System between Toyota and Parts Manufacturers New Toyota Network System (TNS) Production Planning System at Nissan

- How Toyota Shortened Production Lead Time Four Advantages of Shortening Lead Time Components of Production Lead Time in a Narrow Sense Shortening Processing Time through Single-Unit Production and Conveyance Shortening Waiting Time and Conveyance Time A Broad Approach to Reducing Production Lead Time

- Machine Layout, Multi-Functional Workers, and Job Rotation Help Realize Flexible Workshops Shojinka: Meeting Demand through Flexibility Layout Design: The U-Turn Layout Attaining Shojinka through Multi-Functional Workers

- One-Piece Production in Practice Requirements for One-Piece Production Resistance to Working Standing Up Resistance to Multi-Skilling Barriers to Autonomation Attaching Castors Smoothed Production An Example of Improvement for One-Piece Flow: A Factory Producing Cabinets for Use as Flat-Screen Television Stands

- Standard Operations Can Attain Balanced Production with Minimum Labor Goals and Elements of Standard Operations Determining the Components of Standard Operations Proper Training and Follow-Up: The Key to Implementing a Successful System

- Reduction of Setup Time-Concepts and Techniques Effects of Shortening the Setup Time Setup Concepts Concept Application

- 5S-Foundation for Improvements 5S Is to Remove Organizational Slack Visual Control Practical Rules for Seiton Seiso, Seiketsu, Shitsuke Promotion of 5S System

- Autonomous Defect Control Ensures Product Quality Development of Quality Management Activities Statistical Quality Control Autonomation Autonomation and the Toyota Production System Robotics Company-Wide Quality Control

- Cross-Functional Management to Promote Company-Wide Quality Assurance and Cost Management Introduction Quality Assurance Cost Management Organization of the Cross-Functional Management System

- Kaizen Costing Concept of Kaizen Costing Two Types of Kaizen Costing Preparing the Budget Determination of the Target Amount of Cost Reduction Kaizen Costing through Management by Objectives Measurement and Analysis of Kaizen Costing Variances

- Material Handling in an Assembly Plant The Parts Supply System in an Assembly Plant A System for Supplying Parts in Sets (the SPS, or Set Parts System) "Empty-Handed" Transportation

- Further Practical Study of the Kanban System Maximum Number of Production Kanban to be Stored Triangular Kanban and Material Requisition Kanban on a Press Line Control of Tools and Jigs through the Kanban System JIT Delivery System Can Ease Traffic Congestion and the Labor Shortage

- Smoothing Kanban Collection Obstacles to Collecting Smoothed Numbers of Kanban Relationship between Smoothed Collection of Kanban and Parts Delivery Smoothing Schedule for the Timing of Kanban Collection Inventions of Kanban Posts at the Production Site Post-Office Mechanism for Outgoing Supplier Kanaban

- Applying the Toyota Production System Overseas Conditions for Internationalizing the Japanese Production System Advantages of the Japanese Maker-Supplier Relationship Reorganization of External Parts Makers in the United States Solution for Geographical Problems Involving External Transactions External Transactions of NUMMI Industrial Relations Innovations Conclusion

- QUANTITATIVE TECHNIQUES

- Sequencing Method for the Mixed-Model Assembly Line to Realize Smoothed Production Goals of Controlling the Assembly Line Goal-Chasing Method: A Numerical Example The Toyota Approach: A Simplified Algorithm Simultaneous Achievement of Two Simplifying Goals New Sequence Scheduling Method for Smoothing Basic Logic of Sequence Scheduling Sequence Scheduling Using Artificial Intelligence Diminishing Differences between Product Lead Times Computation of the Number of Kanban Computation of the Number of Kanban The Constant-Cycle Withdrawal System for Computing the Number of Inter-Process Withdrawal Kanban Computation of the Number of Supplier Kanban Constant-Quantity Withdrawal System for Computing the Number of Inter-Process Withdrawal Kanban Computation of the Number of Production-Ordering Kanban Computation of the Re-order Point Determination of Lot-Size Changes in the Number of Kanban Maintaining the Necessary Number of Kanban.

- (source: Nielsen Book Data)

- Total Framework of the Toyota Production System. Implementation Steps for the Toyota Production System. SUBSYSTEMs. Adaptable Kanban System Maintains Just-In-Time Production. Supplier Kanban and the Sequence Schedule Used by Suppliers. Smoothed Production Helps Toyota Adapt to Demand Changes and Reduce Inventory. The Information System for Supply Chain Management between Toyota, Its Dealers, and Parts Manufacturers. How Toyota Shortened Production Lead Time. Machine Layout, Multi-Functional Workers, and Job Rotation Help Realize Flexible Workshops. One-Piece Production in Practice. Standard Operations Can Attain Balanced. Reduction of Setup Time Concepts and Techniques. 5S Foundation for Improvements. Autonomous Defect Control Ensures Product Quality. Cross-Functional Management to Promote Company-Wide Quality Assurance and Cost Management. Kaizen Costing. Material Handling in an Assembly Plant. Further Practical Study of the Kanban System. Smoothing Kanban Collection. Applying the Toyota Production System Overseas. QUANTITATIVE TECHNIQUES. Sequencing Method for the Mixed-Model Assembly Line to Realize Smoothed Production. New Sequence Scheduling Method for Smoothing. Computation of the Number of Kanban.

Bibliographic information

Browse related items.

- Stanford Home

- Maps & Directions

- Search Stanford

- Emergency Info

- Terms of Use

- Non-Discrimination

- Accessibility

© Stanford University , Stanford , California 94305 .

How does just-in-time production work?

If you’ve ever studied manufacturing, it’s likely you will have heard of just-in-time production methods. The technique of arranging regular, small deliveries of exactly the correct amount required was pioneered by Toyota .

Just-in-time (JIT) production is a ‘pull’ system of providing the different processes in the assembly sequence with only the kinds and quantities of items that they need and only when it needs them. Production and transport take place simultaneously throughout the production sequence – inside and between all the processes.

The primary objectives of just-in-time production are to save warehouse space and unnecessary cost-carrying and to improve efficiency, which means organising the delivery of component parts to individual work stations just before they are physically required.

To apply this flow efficiently means relying on ordering signals from Kanban boards or by forecasting parts usage ahead of time, though this latter method requires production numbers to remain stable.

Use of JIT within the Toyota Production System means that individual cars can be built to order and that every component has to fit perfectly first time because there are no alternatives available. It is therefore impossible to hide pre-existing manufacturing issues; they have to be addressed immediately.

Discover the 12 other pillars of the Toyota Production System: Konnyaku Stone Poka-Yoke Hansei Andon Jidoka Just-In-Time Heijunka Kaizen Genchi Genbutsu Nemawashi Kanban Muda, Muri, Mura Genba

Share Story

I use to wonder why a part of production equipment wasn’t ready available when needed, now I understand and the concept is brilliant but I would think costly if the company was a make it or break it operations.

I agree wholeheartedly

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

To be the first to hear about all of our latest news, offers and events, check the box below, we’ll send these communications by email, phone, SMS or post. Be assured that Toyota will only share your personal information with companies that are an integral part of fulfilling the services we deliver. If you would like to find out more about how we process your data please visit our privacy policy for details.

Yes, I'd like to receive the latest news, offers and events from Toyota.

I understand that I can unsubscribe at any time.

Related Posts

What is Toyota C-HR Hybrid Insurance?

We reveal how our ground-breaking Toyota C-HR Hybrid Insurance delivers vehicle cover that incentivises cleaner, more efficient driving.

Toyota awards 2024: praise for our cars and people

Our regularly updated list of the awards, achievements and accolades given to Toyota GB's cars, services and people during 2024.

W2RC 2024 result: BP Ultimate Rally-Raid

Toyota Gazoo Racing increased its advantage in the manufacturers' standings following a hard-fought third round of the always-tough W2RC 2024.

How Toyota is contributing to International Women’s Day 2024

What is International Women's Day 2024, and how has Toyota (GB) been contributing to this annual global initiative to #InspireInclusion?

To hear about the latest Toyota news and offers, sign up here

Privacy Overview

More From Forbes

From just-in-time to just-in-case: is excess and obsolete next.

- Share to Facebook

- Share to Twitter

- Share to Linkedin

A container ship loaded with inventory waiting to dock at the Ports of Los Angeles/Long Beach. ... [+] (Photo by FREDERIC J. BROWN/AFP via Getty Images)

Supply chain disruptions and product shortages across manufacturing and retail have caused many people to proclaim the end of just-in-time inventory practices in favor of more just-in-case stocking. Looking at the transcripts of some recent quarterly earnings calls, we are indeed seeing some inventory build-up going on. This might be a good time to revisit the rationale for just-in-time inventory versus just-in-case, because if we aren’t careful, we could be facing a wave of what the accountants call “excess and obsolete,” the write-downs of excess inventory that often follows stocking binges.

Many modern lean manufacturing practices were developed by Toyota after World War II. They were born of an effort to catch up with the American auto industry, who benefited from extensive manufacturing scale and plentiful resources. Taiichi Ohno, an industrial engineer who is considered to be the father of the Toyota Production System (TPS), recognized that the company had to work with limited resources, and he designed a manufacturing system to operate within the company’s constraints. Rather than making large batches of parts at a time, he sought to produce them at a rate that matched demand. Just-in-time was inspired by observing an American supermarket, where a customer took the desired amount of goods from the shelf and the store restocked with just enough to fill the space.

The most important consideration in the Toyota Production System (TPS) is the complete elimination of waste, and Ohno identified excessive production resources, overproduction, excessive inventory, and unnecessary capital investment as foremost. Overproduction led to excess inventory, and created the need for more workers, equipment, floor space and activities to manage inventories. Worst of all, it tied up cash and incurred the risk of write-offs. Defects or design changes were particularly problematic if there was a large inventory of parts on hand or in the pipeline, because it meant they had to be reworked or scrapped. TPS was developed over many years, and techniques such as just-in-time and production smoothing were developed through much trial and error and continuous improvement.

Toyota Factory In Nagoya, Japan In March, 1990. (Photo by Kurita KAKU/Gamma-Rapho via Getty Images)

Western companies first began to understand TPS as a fundamentally different and better approach to production in the 1980s. Perhaps it was the times. R.C. Estall writing in the journal Area in 1985 commented, “current high interest rates, fiercely competitive markets and low profit margins have made inventory management a much more serious matter for manufacturing firms.” He went on to describe just-in-time as “a more lasting possibility of major cost reduction,” citing the potential for reducing cash tied up in inventory. He pointed out that in 1984, General Motors had 3,500 suppliers compared to 225 for Toyota, and carried five days of inventories valued in 1982 dollars at $5 billion. Toyota, in contrast, had perfected a system in which parts for its assembly lines might be delivered daily or several times a day. Much less cash tied up in inventory meant lower production costs which could be passed on to consumers in the form of lower prices.

American companies slowly adopted TPS over the next two decades, slowed by the cultural changes and shifts in mindset that were necessary to a successful implementation. But by the early 2000s, almost every production facility around the world, making everything from cars to phones to consumer packaged goods had adopted elements of TPS under the banner of “lean production” or their own named production system versions. And in many instances, they put long logistics links into their supply chains, for example sourcing auto parts from China to go into vehicles assembled in North America, because those distant sources offered more attractive prices.

Best Travel Insurance Companies

Best covid-19 travel insurance plans, supplier geography.

When Ohno designed TPS, most of Toyota’s suppliers were geographically close. As the company expanded production globally, it also worked hard to ensure that logistics processes would support its production flow. Just-in-time assembly requires strictly scheduled deliveries – a low inventory “pull” system with high frequency, small lot size parts deliveries. For its North American assembly operations, this meant a large, flexible trucking network with dedicated routes. In recent years the company has put increased focus on managing this network so that it could respond quickly to changes, trying to both meet customer demand and minimize supply chain risks. This also included a focus on supplier location, something that is intimately intertwined with logistics planning. Around 75% of material destined for its network of North American factories is sourced in North America, with a heavy concentration in Midwestern states near its major facilities including Kentucky, Ohio, Michigan, the southeast, and southern Ontario. But this doesn’t mean Toyota carries no inventory. It carries strategic levels for things like the microchips used in cars, a lesson it learned after the East Japan earthquake and tsunami in 2011. Notably, Toyota surpassed General Motors in vehicle deliveries last year, thanks largely to comparatively better supply chain management.

Recently many people have been talking about the end of just-in-time, and a shift to more just-in-case, meaning the holding of more inventory. How we feel about this inventory build-up should depend on which sector we are looking at. Many manufactures have been struggling with logistics delays and parts shortages, so having more material on hand can make a lot of sense, especially if it comes off a long supply line from China. But forces like the semiconductor chip shortage have driven a lot of just-in-case ordering. I think a significant part of this is double-ordering, though no one likes to admit they are doing that. In supply chain vernacular, this is called “shortage gaming,” a well-known phenomenon that generally doesn’t have a happy ending. In consumer products and retail distribution, the argument is that sell-through of goods are high, and retail inventories are at historic lows. Yet some retailers have reported higher inventories in stores during their recent earnings calls.

Satellite view of container ships wait to offload at the Ports of Los Angeles and Long Beach, ... [+] California, late last year. (Photo by Gallo Images/Orbital Horizon/Copernicus Sentinel Data 2021)

We should not forget the original rationale for just-in-time: catch quality problems early before you have a lot of defective parts made, lessen the risk of obsolescence (especially in fast moving industries), don’t waste space storing and managing all that inventory, lessen the amount of cash tied up. We currently see a lot of construction of new warehouse space, a lot of hiring to staff them, and congestion slowing the flow of goods from ports to clogged distribution centers. Remember in the case of ocean container shipping in the eastbound Trans-Pacific trade lane, if there are 100+ ships waiting to unload off the ports of Los Angeles and Long Beach, that means a lot of inventory headed our way. If an average ship unloads 4,000 40 foot boxes (known as forty-foot equivalent units or FEUs), that means 400,000 containers full of auto parts, toys, clothing, shoes, exercise equipment and other merchandise that are eventually going to hit our shores. Hmmm … that’s a lot of stuff, and a lot of cash tied up, especially post the peak holiday season. At low interest rates, tying up cash is less of a problem. If the economy slows for whatever reason, say from higher interest rates, that could mean a lot more excess and obsolete as companies everywhere try to reduce the inventory lines on their balance sheets and generate cash. That could be pretty exciting!

- Editorial Standards

- Reprints & Permissions

How One Covid Case Upended Toyota’s Just-in-Time Supply Chain

Early last month at a sprawling factory on the highway connecting Hanoi to the Vietnamese port city of Haiphong, a single worker tested positive for COVID-19. The delta variant was spreading swiftly through the Southeast Asian nation at the time, and on Aug. 4, provincial officials suspended work at the plant, run by an auto-parts manufacturer.

An ocean away, Toyota Motor Corp. Chief Purchasing Group Officer Kazunari Kumakura was watching intently. The factory is operated by a key Toyota supplier and is one of Vietnam’s biggest assemblers of wire harnesses — a basic but essential yoke for cables that holds the inner workings of an automobile together. As the infection at the facility disrupted operations, Toyota’s inventories grew thin. Since July, the Japanese automaker had been examining its suppliers in the region, which has become a Covid hotspot, on a daily basis to assess how dire things were getting.

Eventually, unable to secure a number of parts, including the wire harnesses from Vietnam and chips from Malaysia, Toyota succumbed. The world’s No. 1 automaker shocked the market by announcing it would slash its output of cars in September by 40% compared to previous production plans.

“The big thing was whether operations could continue in Southeast Asia,” Kumakura said in a late afternoon address to reporters on Aug. 19. But lockdowns, growing Covid clusters and government-imposed restrictions on production made it clear that auto suppliers, particularly in Malaysia and Vietnam, wouldn’t be able to continue operations, he said. It “tangled up our parts” and “happened rapidly.”

Toyota is now faced with the challenge of securing substitute parts and recovering lost output in time to meet an inventory-depleting level of global demand for cars. But more broadly, the snarls that finally toppled one of the world’s best-maintained supply chains have sparked deeper questions about whether the auto industry’s strategies to prioritize efficiency and maintain minimal inventory will endure in the post-pandemic world.

Carmakers globally have lost revenue because shortages have slammed output. India’s largest automaker by deliveries, Maruti Suzuki India Ltd., said volume would likely drop to about 40% of normal this month and Tata Motors Ltd. on Wednesday blamed “the recent lockdowns in east Asia” for worsening the supply situation. China’s Nio Inc. has struggled with partners in Malaysia. Also in Japan, Suzuki Motor Corp. will cut vehicle production by 20% in September while in Europe, Renault SA plans to halt assembly plants in Spain for as long as 61 days before the end of the year.

External Shocks

The car sector is accustomed to much thinner profit margins than those enjoyed by big technology companies, even after decades of trying to drive down costs, said Howard Yu, a professor of management at the Switzerland-based Institute for Management Development. Automakers strive to be lean, reducing redundancies and working out of regional hubs because it’s more efficient, he said. “But to be resilient, you need a bit of redundancy. The delta outbreak is exposing that this system is really vulnerable to external shocks.”

Over the past decade, Japanese automakers have invested heavily in Southeast Asia, looking to the region as a source of cheap labor and to supplement their China operations amid trade tensions with the U.S. Thailand is a major production hub for Toyota, Mitsubishi Motors Corp., Honda Motor Co. and Nissan Motor Co. Those automakers make up about half Thailand’s vehicle production capacity and source a number of parts from neighboring countries. Toyota alone works with suppliers that have more than 400 plants located in Malaysia and Vietnam, data compiled by Bloomberg show.

That concentrated approach worked, until it didn’t. Midway through this year, Southeast Asia began to grapple with one of the world’s deadliest virus resurgences. Governments declared lockdowns and restricted business activities, at times halting entire plant operations upon the discovery of just a handful of confirmed cases.

Vietnam is Japan’s biggest source of wire harnesses. Several Japanese parts makers operate plants in the country. The Hai Duong factory that shut in early August belongs to Sumitomo Electric Industries Ltd., which declined to comment on individual site operations. Another major wire-harness maker and Toyota supplier in the region, Furukawa Electric Co., has been forced to limit operations due to Covid restrictions, according to a company spokesperson.

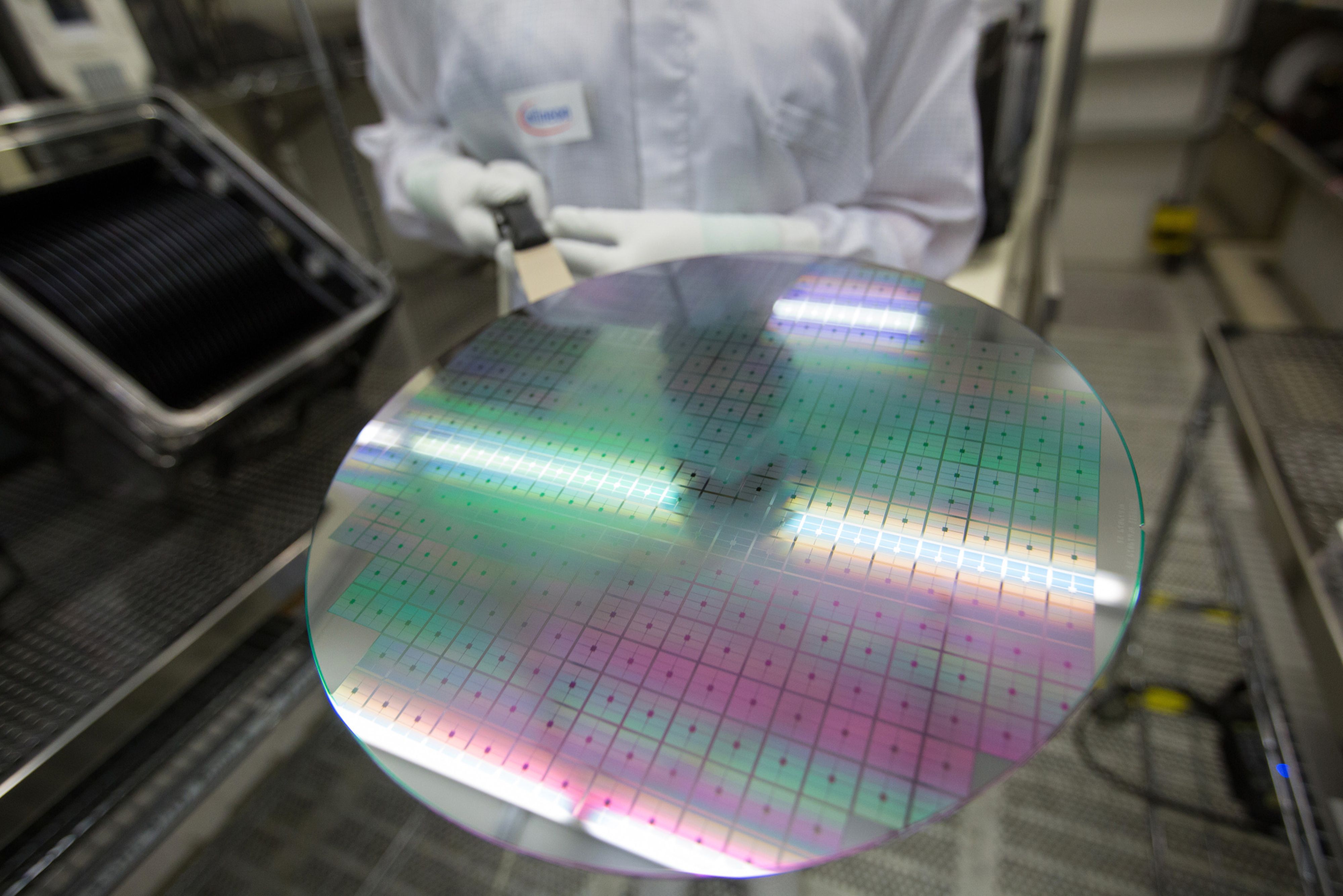

An Infineon Technologies employee displays a 300mm silicon wafer. Photo: Bloomberg.

Similarly, Malaysia has emerged in recent years as a major center for end-stage chip packaging — the smallest and least-profitable component of the semiconductor manufacturing process. Rising Covid cases have forced key auto suppliers STMicroelectronics NV and Infineon Technologies AG to close facilities, worsening a shortage of chips that’s been hammering automakers for months. Bloomberg’s supply chain analysis data show Toyota sources from both of those companies.

Striking a Balance

For now, automotive suppliers in the nations are showing signs of getting on a path to recovery. Most staff at Sumitomo Electric’s Hai Duong wire-harness plant returned to work by around the second week of August, according to the province’s official television station. As of last week, Malaysia’s chipmakers were essentially back to normal levels of operation and Toyota has said it expects to begin to recover lost production in October.

The question remaining is whether this supply chain disruption will spark a long-term shift at Toyota and other manufacturers’ operations.

If the delta outbreak in Southeast Asia proves to be relatively short-lived, it may not make much sense to uproot supply chains, Bloomberg Intelligence analyst Tatsuo Yoshida said. Greater economies of scale are possible with single sourcing and diversifying supply chains requires significant time and money. Hubs have formed in Southeast Asia for a reason — labor-intensive processes can be performed cheaply there, he said.

At the same time, if Toyota’s relatively strong performance amid the pandemic and supply chain mess thus far says anything, it’s that the automaker is willing to take action after breakdowns. The company’s methods of maintaining high visibility into its supply chain and strategy of keeping stock of riskier parts like semiconductors are legacies of 2011, when an earthquake and tsunami knocked its suppliers’ plants offline, disrupting Toyota’s operations for a full half year.

Kumakura acknowledged last month that because production of certain widely used parts is concentrated in Southeast Asia, a disturbance in the region has the potential to ripple across a much wider geography. In the future, Toyota “will look at how to allocate production and diversify risks so as to not concentrate on one specific area,” he said. “We’ll reflect and draw on this knowledge to further strengthen ourselves.”

In the end, it comes down to striking a balance between efficiency and resilience, said Yu, the management professor. Certain parts don’t seem critical until they “blow up production systems” because there are limited suppliers concentrated in a particular region. In a good quarter, dipping into profit to invest in rainy-day resilience is “what long-term perspective is about,” he said. “And this isn’t just a story of Toyota.”

RELATED CONTENT

RELATED VIDEOS

‘VIP-Lane’ Pandemic-Mask Supplier Embroiled in London Trial

Subscribe to our daily newsletter.

Timely, incisive articles delivered directly to your inbox.

Popular Stories

Outpacing Disruption by Regionalizing Supply Chains

Red Sea Crisis Could Bring Early Start to Peak Shipping Season

U.S. Supply Chain Activity Slows in April Amid Mix of Factors

U.S. Manufacturers Praise New Tariffs on Medical Supply Imports from China

The B2B Integration Playbook for Microsoft Dynamics

Digital edition.

2024 Supply Chain ESG Guide

Case studies, recycled tagging fasteners: small changes make a big impact.

Enhancing High-Value Electronics Shipment Security with Tive's Real-Time Tracking

Moving Robots Site-to-Site

Jll finds perfect warehouse location, leading to $15m grant for startup, robots speed fulfillment to help apparel company scale for growth.

Just-in-Time Production Method: Toyota Company’ Case

What is jit.

The JIT commonly refers to the just-in-time method of production. The major area of its implementation is the Japanese car manufacturing. It is a holistic system of managing the process of production. The major objective of this manufacturing method is an attempt to reduce production waste and make as little by-products as possible. For the first time, the system was developed by an engineer Taiichi Ohno and was introduced at the Toyota production on a daily basis.

The idea was holistically simple since the manufacturers considered that with a large number of suppliers of smaller parts for one mechanism, there would be a possibility to reduce the waste. Particularly, each next step of the production would only start when the previous step is finished. Each detail would only be developed when all the details of the previous stage were ready (Womack, Jones, & Roos, 1990). The concept was reflected in the production method’s name. Every stage of production finishes just in time for the next one to begin. The idea was difficult in implementation because it had a major danger of impeding the entire manufacture. In other words, if any of the stages failed the whole process would stop.

What is JIT philosophy?

The philosophy of the JIT principle relies on the assumption that the production with solely the inventory required for a certain stage is more effective. The major principle is to waste neither materials and supplies nor the time. The process of production should be structured and divided into orderly stages, without any chaos or unnecessary waste ( Lean Manufacturing and Just-in-Time Production, 2016). Apart from that, each stage of the manufacturing relies on the previous one, which makes each step of the work more significant both for the managers who administer the process and for the employees who attribute more importance to their work. It encourages responsibility and effective time management on all the levels of the production process, as well as uses the human factor as an advantage of the production.

What did Toyota do to overcome the problems the fire caused?

Due to the recently discovered technical problems, Toyota recalled nearly 6.5 million of its vehicles worldwide. The nature of the problem concerned the majority of the vehicles produced between 2005 and 2010. Particularly, the problem was the potential fire danger because of the inflammability of the power windows and their switches. As a result, the company experienced some major financial losses.

Moreover, it influenced immensely the company’s reputation since it had already had similar recalls in 2009 and 2010. Therefore, Toyota decided with a new motto “Moving Forward” to regain its place on the market as a manufacturer of safe and reliable vehicles and to put to rest the previous incidents (Kelly, 2012). They launched a different marketing strategy but did not give up on their main principles.

What does this experience tell you about just-in-time? That is, what lessons could be learned from the experience?

Although just-in-time has a perfect justification from the theoretical point of view, in practice it is linked to a number of risks. Firstly, an error at a single stage of production can result in the invalidity of the entire process. That factor is hazardous both for the major manufacturers with a large number of produced items and for the starting businesses who are more likely to make some mistakes. The second danger of difficult implementation and the extremely high standards of discipline and quality that are hard to sustain.

Kelly, A. (2012). Has Toyota’s Image Recovered From The Brand’s Recall Crisis? Forbes. Web.

Lean Manufacturing and Just-in-Time Production – organization, levels, system, advantages, model, type, company, competitiveness, system . (2016). Web.

Womack, J. P., Jones, D. T., & Roos, D. (1990). A machine that changed the world . New York, NY: Simon and Schuster. Web.

Cite this paper

- Chicago (N-B)

- Chicago (A-D)

StudyCorgi. (2020, November 14). Just-in-Time Production Method: Toyota Company’ Case. https://studycorgi.com/just-in-time-production-method-toyota-company-case/

"Just-in-Time Production Method: Toyota Company’ Case." StudyCorgi , 14 Nov. 2020, studycorgi.com/just-in-time-production-method-toyota-company-case/.

StudyCorgi . (2020) 'Just-in-Time Production Method: Toyota Company’ Case'. 14 November.

1. StudyCorgi . "Just-in-Time Production Method: Toyota Company’ Case." November 14, 2020. https://studycorgi.com/just-in-time-production-method-toyota-company-case/.

Bibliography

StudyCorgi . "Just-in-Time Production Method: Toyota Company’ Case." November 14, 2020. https://studycorgi.com/just-in-time-production-method-toyota-company-case/.

StudyCorgi . 2020. "Just-in-Time Production Method: Toyota Company’ Case." November 14, 2020. https://studycorgi.com/just-in-time-production-method-toyota-company-case/.

This paper, “Just-in-Time Production Method: Toyota Company’ Case”, was written and voluntary submitted to our free essay database by a straight-A student. Please ensure you properly reference the paper if you're using it to write your assignment.

Before publication, the StudyCorgi editorial team proofread and checked the paper to make sure it meets the highest standards in terms of grammar, punctuation, style, fact accuracy, copyright issues, and inclusive language. Last updated: November 14, 2020 .

If you are the author of this paper and no longer wish to have it published on StudyCorgi, request the removal . Please use the “ Donate your paper ” form to submit an essay.

Just-In-Time - Toyota Case Study

Get full access to Lean Management: Just-In-Time Training and Certification and 60K+ other titles, with a free 10-day trial of O'Reilly.

There are also live events, courses curated by job role, and more.

Get Lean Management: Just-In-Time Training and Certification now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.

Don’t leave empty-handed

Get Mark Richards’s Software Architecture Patterns ebook to better understand how to design components—and how they should interact.

It’s yours, free.

Check it out now on O’Reilly

Dive in for free with a 10-day trial of the O’Reilly learning platform—then explore all the other resources our members count on to build skills and solve problems every day.

IMAGES

VIDEO

COMMENTS

Toyota's Just-in-Time System, in the past there have been situations which ultimately lead to closure of Toyota factories only because of lack of inventory for its production. The output of the research will take the form a case study of three major shutdowns

Mahajan S. (2017), "Implications of Just-In-Time System of Toyota: A Case Study.", March 2017, Ritsumeikan Asia Pacific University from Toyota President Akio Toyoda's Statement to Congress Feb 2010

Not the case, say Toyota executives. TPS is alive and well and is a key reason Toyota has outperformed rivals. ... This led many people to argue that just-in-time and lean production methods were ...

Sarah Jane Johnston: Why study Toyota? With all the books and articles on Toyota, lean manufacturing, just-in-time, kanban systems, quality systems, etc. that came out in the 1980s and 90s, hasn't the topic been exhausted? Steven Spear: Well, this has been a much-researched area. When Kent Bowen and I first did a literature search, we found ...

Keywords: Lean Manufacturing, Just in Time, Kanban system, Case Study, Toyota Production System. I. INTRODUCTION Lean manufacturing is the basic techniques for improve the production rate with the minimum available resources. This concept is comes out after the World War 2. This manufacturing, an approach that depends greatly on

Why Toyota's Just-in-Time Method Is Critical to Its Success. Toyota began using the Just-in-Time method in 1938. However, the true potential of this strategy was realized when it integrated this ...

Conclusion. Toyota's Just-In-Time system is a testament to the power of innovation born from necessity. It's a story of how keen observation, a deep understanding of processes, and the courage to challenge conventional wisdom can lead to revolutionary outcomes. In the annals of manufacturing history, JIT stands as a beacon, illuminating the ...

Whenever you buy a complex piece of equipment such as a TV or a car, do you ever wonder: how exactly did they put this all together? This video analyzes Toyo...

Computation of the Number of Kanban. (source: Nielsen Book Data) Publisher's summary. A bestseller for almost three decades, Toyota Production System: An Integrated Approach to Just-In-Time supplies in-depth coverage of Toyota's production practices, including theoretical underpinnings and methods for implementation.

Integrated Approach to Just-In-Time supplies in-depth coverage of Toyota's production practices, including theoretical underpinnings and methods for implementation. Exploring the latest developments in the Toyota Production System (TPS) framework at Toyota, this new edition updates the classic with

Just-in-time (JIT) production is a 'pull' system of providing the different processes in the assembly sequence with only the kinds and quantities of items that they need and only when it needs them. Production and transport take place simultaneously throughout the production sequence - inside and between all the processes.

Production System" by Yasuhiro Monden, "A Study of the Toyota Production System from an ... The most famous element of the TPS is no doubt the Just-in-Time pillar of the production system. The phrase Just-in-Time was coined by Kiichiro Toyota in 1937 after the start of Toyota ... (just in case), or invest in more equipment (due to ...

The case focuses on the Just-in-Time manufacturing system pioneered by Toyota. The case discusses in detail the Kanban concept, which was one of the principles on which Toyotas JIT was based. The Kanban philosophy is compared with the western manufacturing philosophy, and the JIT system is compared with non-JIT systems. The case also touches on the disadvantages of JIT and the future of JIT

Plant circadian clocks increase photosynthesis, growth, survival, and competitive advantage, and may involve production of certain proteins in a "just in time" manner, anticipating daylight soon enough to produce the photosynthesis machinery, but not so much in advance that certain unstable proteins start to degrade.

He went on to describe just-in-time as "a more lasting possibility of major cost reduction," citing the potential for reducing cash tied up in inventory. He pointed out that in 1984, General ...

We would like to show you a description here but the site won't allow us.

An ocean away, Toyota Motor Corp. Chief Purchasing Group Officer Kazunari Kumakura was watching intently. The factory is operated by a key Toyota supplier and is one of Vietnam's biggest assemblers of wire harnesses — a basic but essential yoke for cables that holds the inner workings of an automobile together.

The JIT commonly refers to the just-in-time method of production. The major area of its implementation is the Japanese car manufacturing. It is a holistic system of managing the process of production. The major objective of this manufacturing method is an attempt to reduce production waste and make as little by-products as possible.

In this video, we will study about Toyota that how it became world's best Car company and how it implemented "Just in Time" & "JIDOKA" model in the organisat...

This paper focuses on the effectiveness of corporate strategy in making engineering organizations successful with a specific case study of Toyota Motors Corporation. The Study uses two approaches ...

This case study also shows the benefits of reduction in waiting period by employing JIT. The conclusion of this research indicates that JIT system is successful and operating JIT system leads to many advantages to the case industry. Procedia Engineering 97 ( 2014 ) 2232 â€" 2237 1877-7058 2014 The Authors.

2005. TLDR. Plant circadian clocks increase photosynthesis, growth, survival, and competitive advantage, and may involve production of certain proteins in a "just in time" manner, anticipating daylight soon enough to produce the photosynthesis machinery, but not so much in advance that certain unstable proteins start to degrade. Expand.

Just-In-Time - Toyota Case Study Get full access to Lean Management: Just-In-Time Training and Certification and 60K+ other titles, with a free 10-day trial of O'Reilly. There are also live events, courses curated by job role, and more.